Center-Drive Offers A Turning Alternative

An interesting aspect of the metalworking industry is that for a given application there is often more than one way to process the workpiece.

Share

An interesting aspect of the metalworking industry is that for a given application there is often more than one way to process the workpiece. We've seen in recent years, for example, the growth of multi-processing machine tools that combine one or more operations on a single machine platform. In many cases, these machines allow a shop to fixture a workpiece blank and perform all of the operations necessary to complete it.

In turning, the imagination has been stretched with the advent of turn/mill, turn/grind, turn/laser and other process combinations. Moreover, the traditional configuration of the VTL (vertical turning lathe) has literally been turned upside down with the popularity of inverted spindle lathes. These innovative machine tools use a carrier-mounted chuck as a combination workholder and part handler.

There is another wrinkle in multi-processing turning center design that hasn't seen much exposure. It is the center-drive lathe concept. Shops with an application for them find the design ideal. But much of the general metalworking industry has not been exposed to the concept.

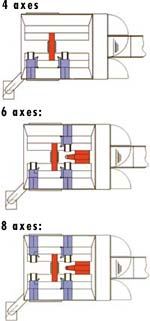

What differentiates the center-drive lathe configuration from other horizontal turning centers is the placement of the machine's headstock unit in the middle of the turning center bed. Slides operate on either side of the headstock and carry the X, Z and sometimes Y axes motions. These machines are built with a minimum of one tool carrier on either side of the headstock. For this reason, they are a least a four-axis turning center. However, there are configurations available that can put four tools on a workpiece simultaneously. These machines use up to eight linear axes of linear motion.

Center-drive lathes are specifically designed to process cylindrical workpieces for automotive, truck, marine and related industries. Because the workpiece is gripped in the middle, both ends can be machined simultaneously. This setup promotes production of close tolerance workpieces owning to a single chucking of the blank. With reduced handling, concentricity and geometric relationships between part features are preserved.

For production applications, the ability to bring two, three or four cutting tools to bear simultaneously on the workpiece keeps cycle times to a minimum. Integrated loading and unloading devices are available to automate the machine for higher volume and lightly attended production.

A newly developed line of center-drive lathes was introduced in the United States at IMTS 2000 by German manufacturer WMS Sinsheim. These lathes are imported by Sytec Corporation (Essex, Connecticut). The design of these center-drive lathes accommodates live tooling and up to two programmable tailstocks for outboard support of long workpieces. Called the C-series, these machines have a 20 kW main spindle drive with 6,000 rpm speed capacity.

The machines are modularly designed and can be equipped with two, three or four tool turrets all programmable from the machine's CNC. Two headstocks are available, and capacity is 15.75 inches in diameter with a standard part length of 10 feet and an optional length of 23 feet.

As shops continue to seek ways to reduce or eliminate multiple workpiece handling, the multi-processing capability of the center-drive concept may be worth a look. It's a proven concept, and maybe it's an answer for your shaft work.

Related Content

Industry Analysis: Machining Semiconductor Components

With many machine shops anticipating long-term growth in demand from the semiconductor industry, it is worth the time to heed the advice of manufacturers who have already been servicing this end-market for years.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreInverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

Read MoreFacilitating Lean Manufacturing Through Modularity

Knowing how to subdivide machines and jobs has enabled Danobat to create a lean manufacturing process that improves its lead times by up to 25%.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More