CAM Toolpath Strategies Push Limits Of Aged VMC

This shop was ready to capitalize on a heavy machine gun sight mount that could save lives in Afghanistan and Iraq, but its older VMC had difficulty producing enough models to bring the prototype to production. Tool paths generated by CAM developer Surfcam’s TrueMill technology enabled the light-duty machine to efficiently hog through the quantities of steel required to make the mounts and win large defense contracts.

Share

ECi Software Solutions, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

As part of what is arguably the most advanced fighting force the world has ever seen, U.S. troops depend on high-tech weaponry and equipment to complete their objectives while minimizing risk to themselves and civilians. However, while new missile systems, robots, unmanned aerial drones and other high-profile advances have changed the face of modern warfare, devices that may seem trivial by comparison can also make a big difference on the battlefield.

One such device has been saving lives in Iraq and Afghanistan for two years. The ATSS MKIII and MKIV sight and illumination mount systems allow soldiers to equip heavy, vehicle-mounted machine guns with the same optical sights and aiming devices used on their M4 rifles and other personal munitions. Rather than a big name in defense manufacturing, the mount was developed by a an entrepreneurial, husband-and-wife team with a good idea and a CAM package that allowed them to make the most of their single, veteran milling machine.

Lowell and Ardis Kenney are the owners of Eagle View Research Center, a Shelton, Washington-based prototype shop. Without the floorspace or budget to purchase a new machine, the couple turned to their CAM supplier, Surfware, to provide a solution that would allow their aged VMC to cut steel more efficiently. The software developer’s TrueMill CAM engine enabled the Kenneys to ramp up speeds, feeds and metal removal rates while avoiding tool breakage, leading to significant cost and cycle time savings. "I may be cutting my own throat, but I know people who adapt TrueMill technology will be able to compete better than those who don’t," Mr. Kenney says.

Eagle View was founded in 2001, when the couple purchased a 1992-model VMC along with the Surfcam 21/2D CAM package and began making aerospace parts from their home. When the terrorist attacks of Sept. 11 sent the airline industry into a tailspin, the Kenneys reestablished their business as a research and development shop. Dabbling in work ranging from outdoor recreation equipment to firearm components, the couple began to design prototypes, figure out the best way to machine them and contract with local machine shops when products were ready for full production.

The business took a decided change when the Kenneys’ oldest son returned from his first tour as an Army captain in Iraq. He brought with him a series of sketches he’d drawn on napkins depicting a mount designed to add high-tech sights and aiming devices to the Browning M2HB .50-caliber machine gun. Commonly mounted on vehicles such as the HMMWV, Bradley armored personnel carrier and Abrams M-1 tank, this weapon is effective against everything from infantry to light vehicles and even aircraft. The gun’s versatility has made it a mainstay in the U.S. armed forces that has seen service in every conflict since the early 1920s.

Mr. Kenney himself had used the M2HB during his service in the Vietnam War, when standard practice was to shoot in the general vicinity of the enemy and then "walk" the rounds into the target. However, the urban battlefields of Iraq and Afghanistan present challenges unlike those faced in most other conflicts, a fact Mr. Kenney’s son understood all too well. "Dad, we can’t range in the gun like you used to," he explained to his father. "We can’t ricochet bullets in the streets of Mosul or Baghdad and expect to win friends—we need to be on target every time."

Once Mr. Kenney had machined a suitable prototype, his son challenged him to make the devices for the whole Army. That became the start of a new division that the Kenneys call Advanced Tactical Sighting Systems (ATSS). However, the shop’s VMC had difficulty cutting the large quantities of CR 1018 steel required to make enough prototypes to market the sight mount. Most machinists would consider that old workhorse to be a light production machine, even for cutting aluminum, Mr. Kenney says. "I was trying to push things as hard as possible, and I was breaking lots of tooling," he explains.

However, after asking Surfcam technical support for help with a programming problem, Mr. Kenney was introduced to a product that could push his old VMC to new limits. The applications engineer asked why the shop was not using TrueMill, a CAM engine designed to create more efficient tool paths. Mr. Kenney was skeptical—he had heard of the software before but thought it was designed primarily for big shops using fast new machines with large memories.

When Surfware provided some feeds and speeds for use with the program, Mr. Kenney set up a piece of 5/8-inch-thick steel used to produce one of the sight mount’s components, an A-frame-style tower that typically took between 17 and 20 minutes to cut. Mr. Kenney reprogrammed the VMC with TrueMill and set up a DNC drip feed so the machine’s limited memory could accommodate the part program. He was so sure he would break a tool that he left a

worn cutter in the machine. With the coolant turned off and a hand hovering over the panic button, he started the machine and waited for the 1/2-inch, TiAlN-coated carbide end mill to break.

He soon realized that the cutting action had never sounded better, and long, thin chips poured from the cut. Sliding the door open and cleaning the pocket with an air nozzle revealed a smooth side wall cut to the full 0.625-inch depth. The spindle load meter had not gone above 25 percent, and Mr. Kenney says the cutting pattern was different than anything he had ever programmed. After a week of testing, he applied higher feeds and speeds. Although these more aggressive settings pushed the load meter to 50 percent at times, Mr. Kenney experienced no crashes or tool breakage and finished the part in about 9 minutes. "I wouldn’t have even cut aluminum like that a year ago—TrueMill just hums," he says.

Most CAM systems generate tool paths based on a given stepover value and the shape of the geometry being machined. However, with this method, the tool’s engagement with the material can radically and rapidly change when it encounters an inside corner, the developer says. This greatly increases the load on the tool and the tool’s temperature, either of which can result in chatter and other undesirable cutting conditions.

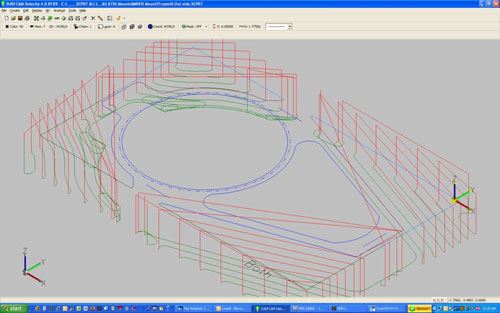

Rather than geometry, TrueMill tool paths are driven by engagement angles—that is, the portion of the cutter’s periphery in contact with the material. Thus, the shape of the geometry doesn’t dictate the flow of the tool path. Rather, each cut is conducted in a way that allows the next cut to proceed at the desired engagement angle. Though the part shape is ultimately produced, it doesn’t become apparent until the final passes of the tool.

TrueMill manages tool engagement by varying stepover according to the toolpath radius and in-process material boundary. In addition to ensuring that the tool is never over-engaged, the software ensures that spindle speed, feed rate and depth of cut stay at set, user-defined limits. According to the developer, keeping all four of these factors constant reduces variation in not only the tool’s load and temperature, but also chip thickness. This allows for more aggressive cutting parameters and a higher, more consistent metal removal rate.

Powering their Surfcam CAM software with TrueMill has enabled the Kenneys to increase depth of cut from 0.2 inch to 0.6255 inch, spindle speed from 2,000 to 6,000 rpm, and feed rate from 15 to 60 ipm. The resulting improvements in cycle time have significantly reduced costs—the aforementioned tower component now costs only $9.75 to produce, compared with $18.42 before TrueMill. "I’m cutting more steel faster and more accurately, and the results are better than ever," Mr. Kenney says.

Moreover, once they determine the best way to machine a part—whether a customer-requested design alteration to the ATSS sight mounts or an entirely new product—the Kenneys can provide TrueMill-generated programs to the job shops they use for mass production. The engagement-driven tool path’s benefits are amplified on these shops’ newer, more sophisticated machines, enabling Eagle View to demand more from its business partners and speed delivery to customers. As a result, the Kenneys are currently working to secure an order for as many as 20,000 sight mounts for the Department of Defense and are considering a shop expansion.

Related Content

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)