CAM Software Helps Shop Take on Complex Work

For Sluterbeck Tool and Die, programming at the machine created substantial downtime. Mastercam Mill Level 1 software improved machine uptime with offline programming.

Share

Even when competent machinists are proficient at writing CNC programs at the machine, the very act of on-machine programming creates inherent downtime in a manufacturing process. To alleviate this, shops must weigh the costs and benefits of investing in a CAM system and programming parts offline. In the case of Sluterbeck Tool and Die Co. Inc., the company purchased a basic seat of Mastercam from CNC Software Inc. (Tolland, Connecticut) to begin improving machine uptime; however, it also discovered new productivity-enhancing features along the way.

Sluterbeck has grown through the years, expanding from its original two-car garage in 1953 to today’s 12,000-square-foot space in Clayton, Ohio, where fourth-generation family member Nick Sluterbeck has worked since 2006. He learned to be a machinist from his father, uncle and grandfather, and through the CNC classes he took at Sinclair Community College. During his time at the shop, business has thrived and the company has added a CNC machine or two almost yearly. Yet in 2011, Mr. Sluterbeck found himself constantly programming at the machine, which created a major amount of downtime. “We would lose an hour at the machine every time we wrote a program instead of moving right into setting up and cutting the next part. That’s when we decided to get CAM software,” he says.

Key software considerations were ease of use and capability for growth as programming requirements became more sophisticated. Mastercam’s Mill Level 1 software met these requirements and was an economical choice considering the basic 2D programming tasks at the core of the business. The day the software arrived, Mr. Sluterbeck began writing part programs. The ability to do this at the same time parts were being manufactured helped the company realize immediate time savings. He eventually obtained certification in both Level 1 and Level 2 training through his Mastercam reseller, and the company currently has a Level 3 license. He also has become proficient with the software’s roughing and contouring capabilities on his own, with some as-needed reseller support.

Beyond ease of use and improving machine uptime with offline programming, Mr. Sluterbeck had no set expectations regarding the advantages that a CAD/CAM programming system might deliver in a multifaceted job-shop environment in which every job can be different from the next. His plan was to investigate various Mastercam productivity tools within the CAM system whenever there were appropriate opportunities. Many of these are now used routinely.

One such productivity tool is simulation for collision avoidance, which enables him to machine even complex shapes at optimal high speeds. “I use it constantly. You can set collision parameters with the holder of the tool shank to automatically eliminate many operator setup errors. It eliminates a lot of stress knowing that you’re not going to hit something major like your spindle. If that goes down, you’re in big trouble,” he says.

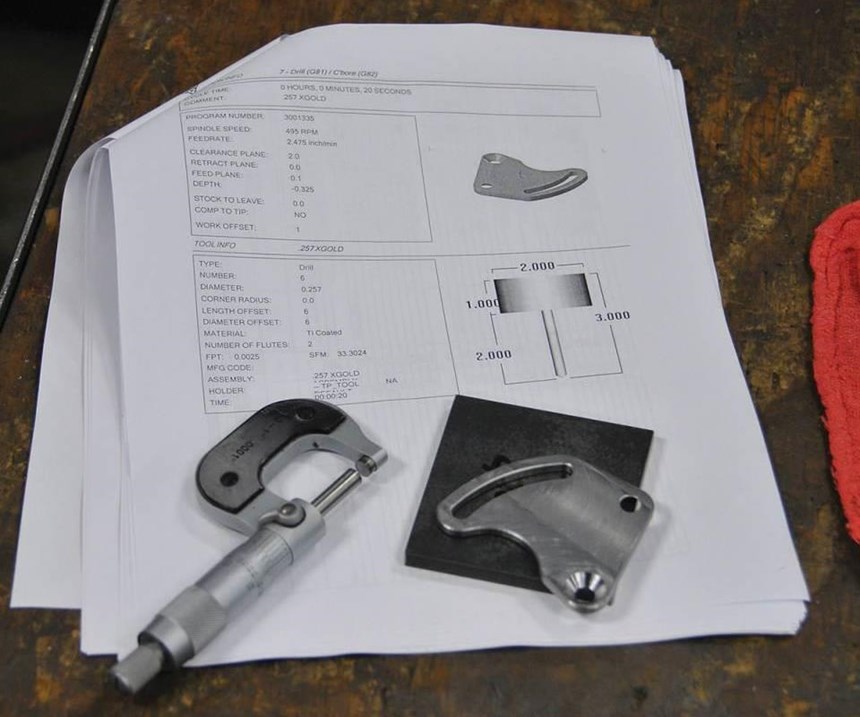

CAM has enabled Sluterbeck to venture into manufacturing unusual and complex shapes if a customer should need them. One prerequisite for doing this is having the ability to prepare the CAD model for CAM programming and also design secure fixturing that allows unrestricted access to critical areas of the part and reduced setups. Mastercam’s integrated CAD package has unique tools for meeting these objectives. For example, Mastercam enabled Mr. Sluterbeck to design fixturing with clearances for a 5-by-10-by-10-inch part that had a pyramid-like shape with multiple angles coming off it. The part was manufactured with the software’s 3D milling features.

Mastercam’s 3D contouring also greatly expands the range of geometric complexity the company can handle and has shrunken setup-time requirements. “One of the biggest things that I try to do is reduce setups and write programs to make parts that are completely chamfered and ready to go out the door. All the machine operator has to do is inspect it,” he says. That type of one-and-done machining strategy is efficient for typical short-run job-shop and prototyping assignments. It also enables the company to compete effectively for production work when quantities need to be increased.

Another productivity tool is constant-chip-load machining. Mastercam’s Dynamic Motion technology enables Sluterbeck to machine parts safely at optimal material removal rates based on the cutting tool vendor’s recommended chip-load setting. The software automatically adjusts tool motions to maintain the correct chip load, even as the tool enters and exits corners, so there is no danger of damaging the tool or the part.

“That’s primarily what I do: high-speed machining, running in the 300- to 400-ipm range on my feed rate with a 10 percent stepover. You can rough out complex profiles in no time compared to what we used to do: taking thick cuts with a big tool that puts a lot of stress on your machine. Those monster cuts used to make my machine vibrate and dance around. Now it sounds a lot cleaner, like a symphony,” Mr. Sluterbeck says.

Mastercam’s nesting tools have also dramatically improved the shop’s productivity. In one case, a complex part with multiple drilling operations required six or seven setups on conventional equipment. Making them one at a time, the shop could produce about 16 a week. Today, three fixtures on the machining center enable parts to be produced in just three consecutive operations using 3D machining at speeds as fast as 400 ipm. With this approach, the shop produces 50 parts per week.

Sluterbeck also has begun performing Y-axis milling and drilling operations on production lathes with bar feeders and parts catchers. The transition to using lathes with live tooling was relatively simple because the Y-axis tool paths are identical to those used in the milling software. This equipment significantly reduces setup times and secondary operations to get parts shipped faster, at even higher levels of quality.

During the past nine years, the shop has experienced significant growth. “It seems like once we got Mastercam, we just started buying machines like crazy,” Mr. Sluterbeck says. In addition to its 2D equipment, the company has grown from one machining center to nine and has also added two production lathes with live tooling. Today, he programs five of the CNC machining centers. Two operators work with him, setting up machines based on setup sheets created within the software, along with loading and unloading the equipment. CAM also makes it possible for the shop to take on more unusual orders. “In the past, we were more likely to turn down very challenging work. Today, we are more likely to say, ‘Oh yeah we can do that.’”

Related Content

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)