CAD/CAM Helps Shop Achieve Tight Tolerances for Medical Components

For Valley Machine, manually programming its turn-mills was time-consuming, requiring multiple edits. Esprit software's CAD/CAM postprocessors eliminated code editing and sped production of complex medical parts.

Share

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

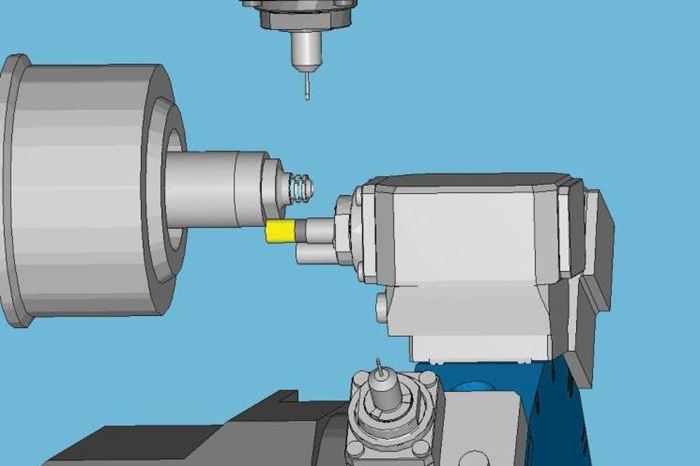

Valley Machine specializes in suppling precision-machined components as well assemblies for customers in the medical, semiconductor, photonics, optics and aerospace industries. To best support this variety of industries, the North Plains, Oregon, machine shop uses a range of equipment, including vertical machining centers; horizontal machining centers; conventional turning centers; two Miyano BNJ42S twin-turret, twin-spindle turn-mills; and an Index C200 three-turret, twin-spindle lathe.

Previously, the manually written numerical control (NC) code for turning centers often required significant editing before it would enable those machines to produce good parts, eating away at the programmer’s available time while leaving the machine idle.

To remedy this, Valley Machine decided to implement CAD/CAM software for its standard turning centers and more complex turn-mill machines. After evaluating numerous packages, the shop chose Esprit CAD/CAM software from DP Technology Corp. (Camarillo, California), in part because of its standard postprocessors, which could generate code that required no editing for the shop’s machines, therefore eliminating the time and cost involved in proving out the code.

The primary feature for generating edit-free code is the software’s multi-channel synching ability, which is said to effectively enable coordinated motion of multiple turrets and spindles on the turn-mills. Another important capability is simulation, which enables programmers to view the complete machining operation offline—including simulated parts, tools and machining—prior to post processing.

After purchasing the new software and attending a week-long training program, Valley Machine immediately began modifying jobs that it had previously run, and it began programming new orders on its two Miyano BNJ42S machines. For these machines, Esprit helped reduce the cycle times required to produce complex parts by moving operations from one spindle to another so that both spindles were continuously working.

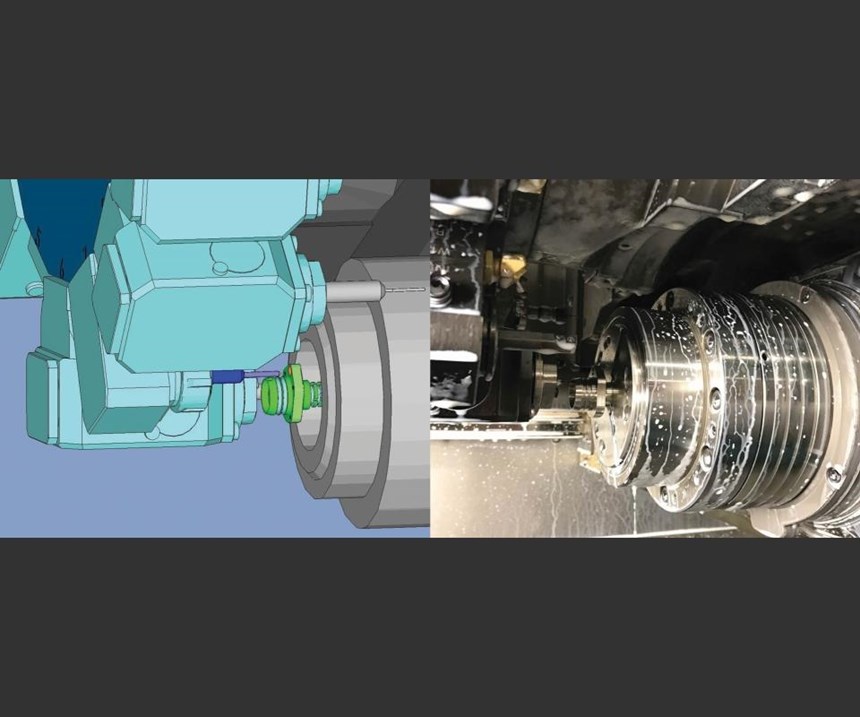

Once the shop was confident Esprit could handle its complex programming needs, it began to optimize the machining capabilities of its new Index C200 to effectively machine an important component for one of its medical customers. This project involved producing 2,000 medical interconnects made from 303 stainless steel. Previously, the shop faced many challenges in trying to manufacture these medical interconnects. For instance, in addition to problematic handwritten programs, the machine on which these parts were originally manufactured could not hold the required tolerances. Instead, the company had to machine the parts on a twin-spindle lathe and then move them to a VMC to machine the face holes and other profiles, which cost valuable production time and money. The company reduced the time required to produce these parts by 30 percent by moving them to the Index C200 machine and using Esprit to quickly resequence cutting operations.

Now, the company can hold tolerances within a few ten-thousandths of an inch by resequencing operations to avoid the potential for deflection that could cause machining errors. In addition, the shop can use the software to produce solid, edit-free lathe programs that help reduce both setup and cycle times, while also improving part quality.

Today, Valley Machine enjoys quicker machine setup times in Esprit with postprocessors that consistently generate accurate NC code, saving valuable machining time and increasing productivity. The shop says it can now efficiently machine any part on its complex turn-mills with the software. Jeremiah Archer, lead programmer at Valley Machine, notes that it is also easy to make changes and try new machining strategies when a part is programmed in Esprit, because the software’s realistic, full-machine simulation enables visualization of each operation. Valley Machine continues to expand its technology and capabilities, and it is gaining additional opportunities to machine more complex parts in new markets with the help of Esprit.

“The support we received prior to even purchasing the product was superior, and immediately providing the help I need is something at which the Esprit support team excels,” Mr. Archer says. “There was never a hesitation when I asked to borrow a machine setup or post for evaluation.”

Related Content

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreCan AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreContinuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=150)