Business Software Reduces Project Time by 75 Percent

When order processing time was on the rise, Southfield Packaging implemented Exact Online for Manufacturing business software to streamline its processes and view real-time business insight anytime, anywhere.

Share

Autodesk, Inc.

Featured Content

View More

While Southfield Packaging in Stamford, Connecticut, is not in the business of making chips and cutting metal, it does face some challenges that job shops can easily relate to. Mainly, it needs to be able to access information about inventory, stock, order status and other key business operations in real-time to remain competitive at providing packaging and fulfillment services to manufacturers. When the company noted that order processing time was on the rise, it turned to Exact Software (Waltham, Massachusetts) for a cloud-based business software that substantially helped reduce project time.

Prior to using Exact Online, the company was using a popular ERP package that was not meeting its needs—it was expensive and it didn’t offer the real-time business insight access the company needed, such as financial data, stock levels and purchase history. Plus, employees commonly worked on Saturdays during the company’s busy spring and fall seasons. Southfield Precision President Mark Melfi began looking for business software that was not only comprehensive enough to meet the organization’s complex needs, but also came with an attractive price tag.

“I run a shop with 25 employees, but I don’t necessarily think of our business as small, so having the right fit in terms of business software makes a huge difference,” he says.

As the business grew, Mr. Melfi needed to consider security. He became more and more wary of making big technology investments without knowing that his business data was secure and wasn’t at risk for deletion or loss, which he knew could be a possibility through the cloud.

The final straw was finding an overall decreased efficiency in the business. Order processing time was on the rise, increasing by 10 percent, making it difficult to take on more business without risking decreased customer satisfaction.

With all of this in mind, Mr. Melfi decided to move forward and transition Southfield’s business data into the cloud by implementing Exact Online for Manufacturing.

The timing couldn't be better. Southfield was working on a large project—a 35,000-piece launch needed for a live airing on a TV retailer network. According to Mr. Melfi, the product was so delayed that once it arrived, he not only had employees working overtime, but he also had to add more employees to the project to treat it with the detail and precision it needed. Though the extra staffing and by using Exact software, Mr. Melfi and his team saved approximately four days of work by streamlining the receiving process, getting samples to the customer on time, and enabling the entire team to monitor the project online from start to finish.

Since implementing Exact Online for Manufacturing, Southfield Packaging has cut order processing time by 65 percent due to its ability to access all of the data employees need on the shop floor and in the warehouse—whether that be a purchase order, inventory reconciliation, lot tracking or item transaction history—with just a few clicks.

This is the dashboard. It enables the foreman or management to see a high-level view of what is going on in the shop with the ability to drill down and get more details. It also has task and alerts to keep things from falling through the cracks. (Click on photo to enlarge.)

Employees can access the cloud-based manufacturing software via their smartphones or tablets whether on the floor or in the warehouse, or even after-hours outside the facility, so jobs can get underway quickly. As a result, Southfield Packaging has been able to take on more orders while simultaneously relieving a burden on its employees.

According to Mr. Melfi, the most important and useful capability of the software is its streamlined logic of the entire manufacturing process. He finds the ad-hoc reporting capabilities particularly useful, as well as the ability to integrate with any application on his mobile device.

“Just knowing that whatever data I need is available to me whenever I need it and through whatever medium I have on-hand gives me great peace of mind,” he says.

In the spring of 2015, Southfield processed more orders than it did in the same time period the previous year without logging any overtime, reducing project time by nearly 75 percent. Additionally, the organization has cut its overall technology costs by using a cloud-based solution that doesn’t require the company to continually invest in new equipment and maintenance.

“Time is money,” Mr. Melfi says. “There isn’t an exact science to qualifying our cost savings, but I will say that the benefits we experienced with our old software cannot compare to the time and money we’re saving today. There’s no way to quantify that, but once you experience it, there’s no looking back.

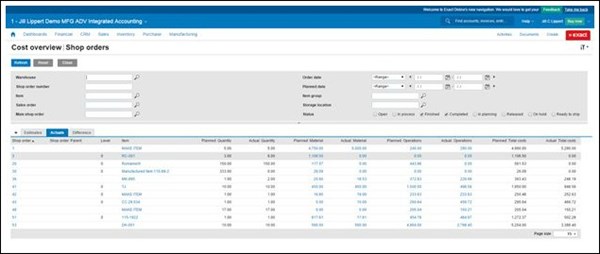

This is the page used by management to determine if job are profitable. It also assist in planning for the next time they do the job by comparing what was planned to what actually took place. (Click on the photo to enlarge.)

“It’s clear that Exact built its online software with small-business DNA in mind. Not only are we more efficient since using the product, by my employees also love to use it on the device of their choice. Getting Exact Online is one of the best things I ever did for our business,” he says.

Related Content

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreCan AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreCan ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)