Burning Away the Burrs

Searching for an efficient means of deburring internal passages led this company to develop a specialized machining cell that incorporates thermal energy to smooth away rough edges.

Share

Autodesk, Inc.

Featured Content

View More

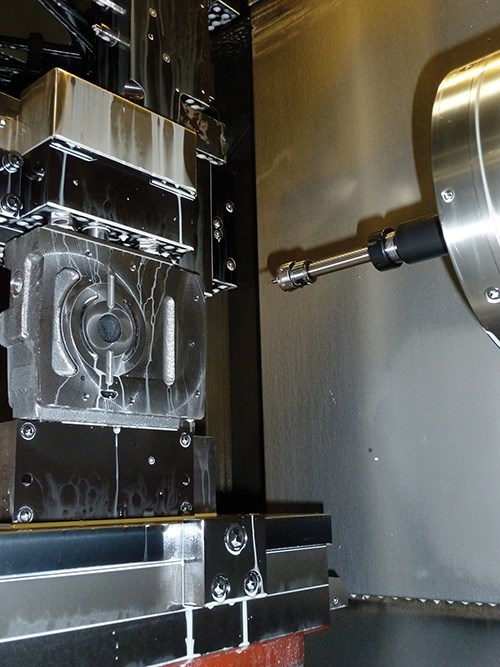

Removing burrs in a flash would seem to be the perfect solution for an automated cell that had to be developed for a new product line to be manufactured in the United States. The mandate to Danfoss Power Solutions’ cell designers from its global headquarters was straightforward: Be able to take a raw casting through machining, measurement, marking, deburring and washing so that the finished part could then go directly to final assembly. The stiffest challenge to the designers, however, involved deburring of the deep, threaded holes that would be bored into the part. Traditional deburring methods were studied and eventually ruled out, considered too difficult or requiring too much time to meet the cycle time parameters set by the project managers.

Ultimately, Danfoss designers were able to incorporate into the cell a process that does, in fact, remove burrs “in a flash.” This thermal energy method (TEM) involves igniting a mixture of methane gas and oxygen inside a chamber that can be robotically loaded and unloaded with machined workpieces. The combustion creates an extremely intense, but extremely short, burst of heat energy that literally burns away all burrs instantaneously, leaving the rest of the part unaffected except for a slight residue of oxidation. Total time for the deburring operation for each batch of parts that fits into the chamber is less than one minute.

Because quickly removing burrs has been successful in this cell, which also includes four HMCs, Danfoss has been able to meet its production requirements since the cell went into operation in 2008, and it is currently producing 64,000 assembly-ready parts a year. The cell requires only one operator per shift, addresses safety and environmental concerns, and is expandable.

Getting to this point did not happen in a flash, however. The cell designers knew that, although the assignment handed down in 2006 was fairly straightforward, the stakes were high, the learning curve would be steep and the cell would require a significant capital investment. But the payoff was an efficient system for transforming a casting into the central components of a new product line in a matter of hours, from machining to assembly.

Thinking Nontraditionally

Lubos Hanulik, the engineer and product line manager who headed up the design and installation efforts for this manufacturing cell, quickly recognized that the traditional method of manual deburring using air pencils and brushes would take too much time and effort, so in addition to mapping out how such a cell would function, he knew the company would need to explore all the latest deburring technologies. High-pressure water deburring was first on the list for consideration. Although this method works well for certain materials, such as aluminum, it wasn’t effective on the cast iron part in question, even at pressures as high as 10,000 psi. Robotic deburring was attractive in terms of automating the process, but the cycle times required by the project parameters could not be met using this method. After working with equipment manufacturers and trying a number of different configurations involving these two approaches, all to no avail, Danfoss decided to look more closely at a process already in use at one of the company’s manufacturing facilities overseas.

“We were using the thermal energy method, or TEM, to deburr parts at one of our plants in Slovakia,” Mr. Hanulik recalls. (A native of that country, he had started his engineering career with Danfoss Power Solutions there.) “We were familiar enough with the process to know that it worked, but also that we had a lot to learn before we could determine whether or not it would fit into our plans for an efficient, streamlined machining cell,” he says.

Concerns included the safety of the process, which involves igniting a mixture of oxygen and methane gas, and how those gasses would be handled, delivered and maintained. Then there was the matter of parts washing—would both a pre- and post-deburring wash be required? Could a chemical be substituted that was less-toxic than the sulfuric acid traditionally used to remove oxidation resulting from the TEM process? Surface finish was also a major concern, of course, if the company was to meet the goal of producing a part that was ready to go directly to assembly.

Danfoss, a global company, encouraged a global search for answers to these questions and concerns.

Cell Division

Headquartered in Nordborg, Denmark, with manufacturing facilities in 19 countries and primary markets of China, Germany and the U.S., the Danfoss Group is comprised of four divisions including Drives (power electronics), Cooling (refrigeration and air conditioning controls, industrial compressors), Heating (residential heating, commercial controls) and Power Solutions. This last division focuses on hydrostatics, work function and controls.

In 2006, Mr. Hanulik found himself at the Danfoss Power Solutions facility in Ames, Iowa. It was his second stint at the plant, where he had already overseen the launch of a new product line some years earlier. When the Danfoss Group decided to manufacture another new product line in the U.S.—a hydrostatic transmission for heavy equipment primarily used in farming and construction—he was charged with developing, from scratch, a new and improved method for manufacturing this product’s central components: the end cap and the connector. All he was told was that, beginning with a casting, he was supposed to deliver a finished part, ready for assembly. It was his responsibility to figure out the fastest and most cost-effective way this could be accomplished.

He knew that the processes within this manufacturing cell would include CNC machining, measurement, marking the part, washing and deburring. How to connect these processes in an efficient system that could be run by a single operator would be determined with the help of various equipment makers, third-party integrators and Danfoss engineers. Mr. Hanulik began reaching out to companies to develop proposals for the cell, asking them to specify what type of equipment it would contain, how it would be configured and what types of processes it would use, particularly how it would deburr the internal passages of the parts.

“There were really no limitations in terms of what the cell would contain and how it would be structured,” he recalls. “There were just goals involving cycle times and costs per part. And I had to justify whatever proposal I ended up presenting, from a financial standpoint.”

A number of CNC machine tool manufacturers, including Mazak, were invited to submit proposals. Industrial Tool Inc. (ITI), a systems integrator based in Minneapolis, Minnesota, and Kennametal Extrude Hone, manufacturer of the TEM equipment Danfoss had already purchased for its plant in Slovakia, also were contacted.

Mr. Hanulik managed the roles and responsibilities of the bidding team members, culminating more than a year later in separate proposals from all those involved. In the end, he decided to move forward with a cell design incorporating Mazak HCN 6000 horizontal milling machines, FANUC robots and a custom-designed washer from Extrude Hone, who would also provide a P400 five-station TEM machine for thermal deburring. Although the cell’s final form was beginning to materialize, there was still much work to be done. While the engineers and operators who would be running the cell were quite familiar with CNC machining, none of them had worked with TEM deburring, and even Mr. Hanulik’s experience was somewhat limited.

Feel the Burn

The thermal energy method involves two principles: combustion and oxidation. The parts to be deburred are first loaded into the combustion chamber of the TEM machine. The chamber is then sealed, and a fixed volume of methane (the fuel) and oxygen is then compressed into the chamber in amounts determined by the part material, the burr thickness and the number of parts being processed. The oxygen is stored in a tank outside the building, and the gas is piped in as a utility. Mixing takes place outside the facility as well, and the mixture is then pumped to the TEM machine inside.

A spark system ignites the mix, resulting in a burst of heat reaching 6,000°F and lasting only a few milliseconds. The burrs, which are so much smaller than the workpiece itself, are instantly burned away, no matter where they are located on the part, with its larger body acting as a heat sink. This leaves an oxidized residue that does not bond with the surface of the part. Once the part has cooled, it can be cleaned in an immersion bath. Although some companies rely on sulfuric acid for this final cleaning, Danfoss uses a neutral solution that can be processed by its onsite water filtration system.

With TEM established as the deburring method of choice and the makeup of the rest of manufacturing cell secured as well, a mock cell was assembled at ITI’s facility in Minneapolis and extended testing was conducted. The results were good: The cell produced a clean part, free of burrs, with an excellent surface finish and ready for assembly. The deburring part of the process took less than one minute. Mr. Hanulik was ready to make his proposal to the company’s executive team. Here’s how the system worked:

Crated castings are placed on two conveyors at the cell’s entrance, one for end caps and the other for connectors. They are loaded manually with an overhead vacuum tool. A robot picks up the parts and loads them into the HMC.

Once the part has been machined, the robot carries it to the measurement machine, which checks the accuracy of its dimensions, and then onto another conveyor leading into the washing/deburring area of the cell.

A separate robot loads the parts from the second conveyor into a basket for pre-washing, and then lifts them from the bath and places them in a layer on a pallet.

The second robot transports the parts from the pallet into the TEM machine’s combustion chamber, where five are placed at a time onto separate fixtures that are specially designed to withstand the high temperatures.

After the deburring cycle is completed and the part has cooled, the robot loads the workpieces into another basket for a separate post-wash. (Kennametal Extrude Hone designed the three-chamber parts washer/filtration unit especially for this application.)

Parts are then loaded onto a final conveyor to be marked by a pin marking machine prior to being loaded for transport to the assembly area, some 50 feet away.

Although what has been described in this article is an extremely condensed version of a multiyear process involving the advice and guidance of professionals from a variety of metalworking fields, the result was approval of the machining cell described above.

In addition to the aforementioned benefit of elimination of all burrs on the machined part, regardless of their location, TEM deburring, unlike traditional mechanical deburring, leaves no material behind in internal passages, so no secondary burrs are produced either. And because it is a non-contact process, there is no chance of damaging the surface finish on the part. Finally, extremely high production rates can be achieved at a very low cost, since the process can occur continuously and very little gas and electricity is required.

In addition, the cell can be run by a single operator, and the model is expandable should production volumes increase. Initially installed with a single CNC machine tool, Danfoss’s cell now features four machines linked by the company’s proprietary monitoring network.

Taking Ownership

It’s been seven years since the machining/deburring cell went into production at Danfoss, and Mr. Hanulik says that lessons have definitely been learned along the way. From an organizational standpoint, he says he wishes he’d spent a bit more time planning the scope of responsibility that all the players involved in the project would be expected to fulfill. Even so, he admits that the organic nature of the process forced all members of the team developing this cell to be flexible and willing to adapt as the project evolved. Some things simply couldn’t be anticipated.

Operationally, with the bulk of the group’s attention focused on joining all of these different technologies into a unified whole, some things were overlooked in the cell’s original design, such as fixturing. Even though non-critical parts can be loaded directly into a basket within the TEM machine’s combustion chamber, the parts being deburred in this operation—each weighing some 35 pounds—were shifting during ignition of the fuel, throwing them around with such force that damage to the surface finish was a concern. Fixturing had to be developed that would hold both the parts being deburred and would also withstand the blast. There could be no welded seams, since the welds would deteriorate during the process, and special heat-resistant materials had to be used—in this case, 316 stainless steel. In addition, even though the fixturing must be replaced every few years, it provides benefits beyond protecting the part, such as ensuring uniform energy distribution.

The biggest discovery, however, wasn’t a surprise so much as a validation of Mr. Hanulik’s approach to management. One of the many decisions he had to make very early in the process of developing the manufacturing cell was who among the company’s employees would be the best candidates to operate the cell. Once the three individuals had been identified, they were made an integral part of the entire planning process, even traveling with Mr. Hanulik to conduct tests offsite and to meet with all of the team players. He is convinced this is a central part of the project’s success.

“These guys were involved in all the conversations we had and all of the decisions we made,” he says. “They provided their input, and they took ownership. Now each of them can run the cell on his own, and they’ve become experts on TEM deburring.”

Related Content

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

Read MoreFour-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

Read MoreHow to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=150)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)