Bridging a Skills Gap with Micromachining

As experienced model makers aged out of the jewelry industry, R&D Manufacturing found a faster alternative to hand crafting in Datron’s Neo micro milling machine. It all came down to rpm.

Share

ECi Software Solutions, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Takumi USA

Featured Content

View MoreOn the surface, R&D Manufacturing may look like any other 100-employee U.S. manufacturer working in sectors like aerospace or automotive, designing and producing metal end products. But R&D Manufacturing manufactures jewelry parts for brands like Tiffany and Co. and Bryan Anthonys, which may order as many as 1 million pieces a year. Not all of the company’s customers are that big; many are artisans who bring new design ideas with orders requiring as few as 25 pieces. Regardless of material and size, jobs often require moldmaking.

Starting off as a new company in 2003, R&D Manufacturing grappled with a jewelry industry that had experienced a twofold change. Enough machine, engineering and moldmaking capacity had moved overseas that there was a noticable loss of knowledge and skill as experienced model carvers for jewelry molds had aged out.

Phil Montalto, who had experience in the manufacturing sector redirecting negative-growth businesses, joined the company in 2010 as CEO. “When I got involved with R&D Manufacturing, I was just looking at creating some efficiencies and trying to figure out how we could keep a jewelry manufacturing business alive in this new era.” But the task became filling a void left by hand craftspeople. “Our challenge was figuring out how to adapt some machine tools to the industry by taking the CAD capabilities that we already had harnessed, and then coupling those with technology that could yield something close to what a human can make by hand. I didn’t know how to do that.”

Becoming a Machinist

Design engineer Marc Fournier took the reins in researching and finding a solution to the problem. “I learned that it all came down to rpm,” he says. “We needed to be able to run really small tools in order to get that handmade look and intricate detail. I realized this wasn’t going to come from a 12-foot-long metal-hogging CNC or a high-speed mini mill using air spindles with high failure rates. When I found Datron on the internet, their solution looked promising.”

A trip to Datron’s Technology Center in New Hampshire confirmed Mr. Fournier’s intuition. He and Mr. Montalto were pleased both with the technology and the Datron staff. “I am not a machinist. I do not talk the talk. I may have been asking questions wrong, but they knew what I was getting at and were able to explain everything to me in layman’s terms that I could understand.”

In the end, the company acquired a Datron Neo milling machine, which has a 40,000-rpm spindle. In fact, R&D Manufacturing was among the first manufacturers in North America to install one. The Datron Next touchscreen interface and control software was particularly useful to Mr. Fournier, providing an easy workflow to leverage his significant CAD expertise without requiring him to be a trained machinist. The machine uses an integrated camera/probe combination designed to speed up the time-consuming task of setting up jobs. The camera shows the machining table below, and the operator can select the workpiece by tracing the area on the touchscreen where the workpiece is displayed. Once the part is located and the machining parameters are set, any irregularity is automatically compensated for in the software. This virtually eliminates part rejection due to improper setup, the company says. An onboard CAM Assistant guides the operator through the program and tool management on an interface that has the look and feel of a smartphone.

All of these tools combined to help Mr. Fournier, a novice operator, create machined parts. “I’m a CAD person, and the Neo has gone into my workflow flawlessly,” he says. “I’m learning machining, and it’s been such an easy transition. What I love so much about this machine is how versatile and how simple it is. With the pneumatic clamping system, one minute I could be milling a block of teak and the next I’m milling aluminum. I literally never know what’s going in that machine. The Neo has grown our capacity tremendously.”

A 4,000% Improvement (Literally)

Currently R&D Manufacturing is using the Datron Neo almost exclusively for product development, prototyping, and the creation of master models, one-offs, and unique pieces. These would normally take an experienced hand model maker three or four days to create. With the Datron Neo, the shop can produce them in about 15 minutes. More complex pieces may take up to 2 hours.

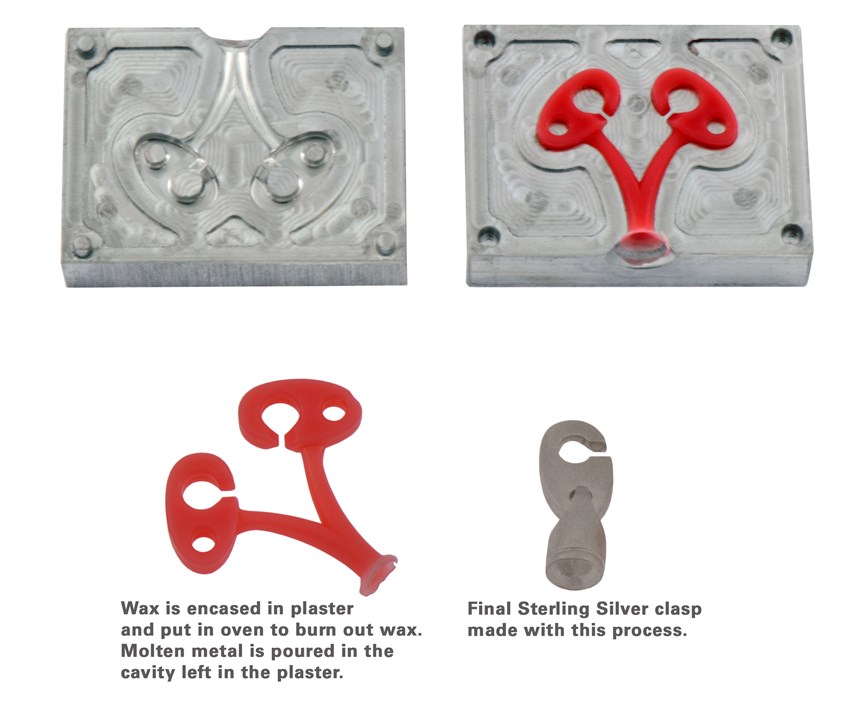

The company manufactures as many components, tools and machines as possible by casting with molds as well as using pneumatic stamping and striking using dies. These are the two biggest starting points for generating a base piece before it goes through the rest of the production process. The company performs enameling, polishing, inspection, mass finishing, soldering, assembly, milling, EDM, laser welding, engraving, die pressing, casting and other processes in house. 3D printing is another technology to be found in the shop.

However, unlike many other companies in the jewelry industry, R&D Manufacturing has been moving away from 3D printing in the creation of master models and prototyping because the Neo allows the company to machine a metal model and skip the casting from the wax 3D print. Now it can go straight to the model or straight to the mold and skip a number of steps. Mr. Montalto marvels at the difference: “A project used to take 12 hours to 3D print, and then we’d send it into casting, wait for it to come back and then polish it. The process would take a week if we were lucky. So, let’s quantify: We went from a week to 15 minutes. Even a 30-minute cut is a 4,000% improvement. The Datron Neo is 240 times faster than the casting process, and we are completing the process within our own facility.”

This advanced technology and added efficiency has helped R&D Manufacturing grow, which has also contributed to the growth of its customers. For example, one young couple who started a jewelry brand with an order for 20 pieces five years ago went on to order almost a million pieces in 2018.

Reflecting on these numbers, Mr. Montalto says of the Neo: “We don’t really know what the capacity is. We haven’t gotten there yet.”

Related Content

How to Pass the Job Interview as an Employer

Job interviews are a two-way street. Follow these tips to make a good impression on your potential future workforce.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreFinding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

Read MoreHow I Made It: Amy Skrzypczak, CNC Machinist, Westminster Tool

At just 28 years old, Amy Skrzypczak is already logging her ninth year as a CNC machinist. While during high school Skrzypczak may not have guessed that she’d soon be running an electrical discharge machining (EDM) department, after attending her local community college she found a home among the “misfits” at Westminster Tool. Today, she oversees the company’s wire EDM operations and feels grateful to have avoided more well-worn career paths.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)