Share

On their own, automatic pallet changers can increase a shop’s throughput. But these systems still require an operator to load and unload the pallets. On the flip side, collaborative robots, or cobots, can reduce a shop’s man hours, but it’s a slower form of automation. These robots have limited speeds compared to traditional industrial robots, which makes them safe to use without cages or fences and easy to integrate on a shop floor. But it also means that the machine tool is sitting idle as the cobot loads and unloads parts. Combining the two forms of automation can help shops maximize unattended machining time. Midaco, which has a wealth of experience with automatic pallet changers, now offers a cobot mount for its automatic pallet changers that can help shops add robotic automation to their pallet changers.

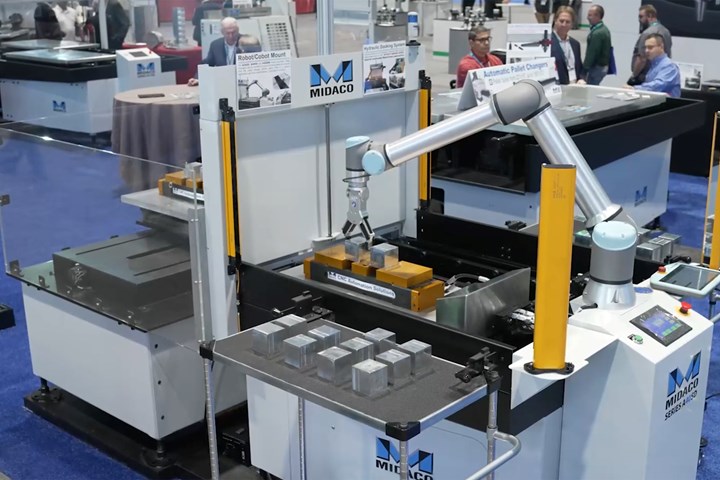

Midaco showcased its Robot Ready automatic pallet system at IMTS 2022. The demo included Midaco’s cobot mount, a UR cobot, its automatic pallet changer for VMCs and hydraulic docking system. Photo Credit: Midaco

Combining a pallet changer with a cobot enables the machine to continue running while the cobot loads another pallet. “Adding the collaborative robot (to the pallet changer) just reduces the man hours necessary to keep the machine running,” explains Mike Munao, vice president of sales at Midaco. “It becomes more machine-driven rather than man-driven.” Say a shop has an automatic pallet changer with two pallets, with each pallet taking an hour to machine. That gives the shop two hours of unattended machining time before an operator needs to switch out the parts. A cobot can use the hour that the one pallet is in the machine to unload and reload the other pallet. The limit for unattended machining then becomes how many blanks the shop can stage for the system.

As the labor shortage continues, shops are continuing to look for ways to increase unattended machining. “There are no operators necessary once it’s up and running,” says Michael Cayley Jr., vice president of manufacturing at Midaco. “So for companies today who can’t find the labor to help them out, it’s a definite way to go.”

“There are no operators necessary once it’s up and running,” says Michael Cayley Jr., vice president of manufacturing at Midaco. “So for companies today who can’t find the labor to help them out, it’s a definite way to go.”

Two Forms of Automation Are Better Than One

The cobot mount is not Midaco’s first foray into combining robotic automation and palletization. In the mid to late 2000s, the company started showcasing applications with automated pallet loading and unloading, but they used full industrial robotic arms that required safety cages, taking up valuable floor space. Midaco introduced the new mount a few years ago, enabling shops to reap the benefits of collaborative automation. Cobots have limited force and speed, and use light curtains for safety instead of fences or cages, which saves floor space. “With the introduction of the collaborative robots, the price point on the robot is more attractive to job shops,” Munao adds.

The mount can be added to new or existing Midaco pallet changers, and users have the ability to choose the type of cobot. The mount is compatible with cobots from Universal Robots and FANUC, but could be expanded to include other brands as well. Users can also select the best way to present blanks to the cobot arm, whether it’s a staging area, cart or conveyor belt.

While one pallet is in the machine, the cobot can load another one, increasing throughput when compared to applications that use just a cobot for machine tending, and giving more unattended machining hours than applications with just a pallet changer. Photo Credit: Midaco

Midaco’s cobot-fed Robot Ready automatic pallet system works with VMCs or other similarly configured machines (such as CMMs, surface grinders or laser marking machines). Applications are limited by the cobot’s payload capacity, so the system works best with smaller parts. And because collaborative robots are designed to be easy to program, this system is well-suited to high-mix, low-volume environments. “The cobot can be loading families of parts on one pallet and do something different on the other pallet,” Munao says. “It just makes the machine more versatile.”

The company also describes one application where a customer had parts that were 30 inches long. Positioning a robot in front of the machine to load parts through the front door would have taken up too much space and made it difficult for operators to perform tasks inside the machine tool. But with the Robot Ready automatic pallet changer mounted on the side of the VMC, the front of the machine remains fully accessible.

Another user found that adding a pallet changer was useful for loading non-uniform parts. In these applications, the robot requires extra time to correctly orient the parts for loading, so being able to perform this task while one pallet was in the machine increased throughput.

The cobot arm’s reach determines the size of pallet that can be used. For example, Universal Robots’ largest cobot, the recently released UR 20, has a reach of 68.9 inches, making it compatible with Midaco’s AS50SD pallet, which is 50 inches long by 20 inches wide. Munao says that this pallet could hold 50 parts or more, depending on part size.

Midaco’s hose-less hydraulic docking system provides an automated way to clamp parts for unattended machining. The pallet sits in the docking station as the robot loads the blanks, then it locks the fixtures into place and sends the pallet into the machine. When the cycle is complete, the pallet returns to the docking system, which automatically releases the parts for unloading. Photo Credit: Midaco

Docking Points

Midaco also offers a hydraulic docking system that helps enable unattended machining. “Using a robot, there needs to be an automated way of clamping parts,” Munao notes. Typical hydraulic clamping systems require the use of hoses, which are dragged into the machine along with the pallet, causing them to wear out quickly. But Midaco has developed a hose-less hydraulic docking system that works well with robotic applications. The pallet sits in the docking system while the robot loads the blanks. Then it locks the fixtures or vises in place, which stay charged as the pallet goes into the machine. When the cycle is complete, the pallet returns to the docking system, which automatically releases the fixtures so the robot can unload the pallet and reload it with more blanks.

Automation Made Simple

Munao says the pallet system with cobot mount is designed to simplify the combining of these two forms of automation. “That’s why we’ve put this package together, to take the complexity out of it,” he says. “So that once the customer learns how to program the collaborative robot, there aren’t any additional hurdles to using it on the pallet changer.”

Related Content

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreWhich Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

Read MoreRead Next

When Too Many Customers Spoil the Part

Duo CNC used to take on as many customers as the shop could handle. But when growth stalled, a top-down audit by the company’s general manager revealed that its customer base was inhibiting growth — and causing the shop to be less efficient and productive.

Read MoreView From My Shop Episode 4: Prototype Machining From a Garage Shop

Guy Driscoll’s shop, Metal Parts Machine, is a garage shop that found success with automation. This mom-and-pop shop uses lights-out machining to run parts with 5-axis capabilities, cobots, pallet changers and more.

Read MoreQ&A: How Universal Robots Developed the UR20, a New 20kg Industrial Cobot

Anders Beck, VP of Innovation at Universal Robots, talks about the journey to building a cobot that pushes the boundaries of the technology’s capabilities.

Read More