Benchmarking: A Measure of your Shop’s Success

Learn about the second edition of our Top Shops benchmarking survey and the types of shops that participated. Further survey analysis is found in three articles other articles.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

The best way to determine whether your shop is as successful or effective as it could be is to compare its key performance indicators with industry leaders. Our Top Shops benchmarking program enables you to do just that.

Launched last year, Top Shops offers all types of shops the chance to see how they stack up against similar companies. Our 2012 program began early in the year with a comprehensive online survey that identified shopfloor practices as well as operational and business metrics that define world-class competitiveness in discrete parts manufacturing.

Shops that participated recently received three reports that present survey data broken out by shop type (captive, contract and job), gross sales and number of parts produced. They also received an Executive Summary that compares performance data of the Top Shops benchmarking group with the other shops that took part in the survey. The benchmarking group is a collection of the best-performing shops determined by totaling the points assigned to certain financial- and technology-related survey questions.

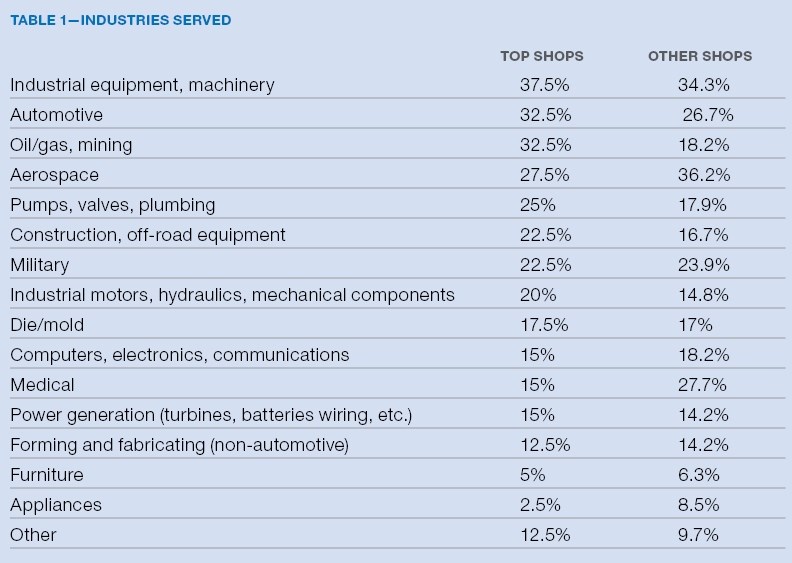

This year, more than 500 shops completed at least a portion of the survey. For analysis purposes, we considered only the 358 shops that answered at least one of the questions used to identify the benchmarking group. Table 1 to the left offers a glimpse at the type of companies that took the survey.

Further Analysis

The following three articles in this special Top Shops issue highlight noteworthy findings from the survey:

- Top Machining Strategies and Shopfloor Practices—Learn more about the machining techniques and technologies applied at leading shops.

- Defining Business Characteristics of Top Shops—Find out about the sometimes atypical financial and human-resources strategies that enable the Top Shops to achieve a higher level of business performance.

- What’s the Secret to Success?—Consider these key shopfloor approaches that the Top Shops identify as major contributors to their overall success.

Honor’s Program Successful Seven

Our Top Shops program includes an Honors Program to highlight a few of the interesting shops that comprise the Top Shops benchmarking group. Vetted by Modern Machine Shop senior editor Derek Korn, these shops represent a quality cross-section of U.S. machining businesses relative to location, size and industries served. Those named to the Honors Program for 2012 are listed below.

- Hoyt USA, Salt Lake City, Utah

- L&H Industrial, Gillette, Wyoming

- Leggett and Platt, Carthage, Missouri

- McCoy Global, Broussard, Louisiana

- Premier Machining Industries, Midland, North Carolina

- Southern Machine Works, Duncan, Oklahoma

- Toth Technologies, Pennsauken, New Jersey

Related Content

-

Machine Shop Mastery: Insights from America’s Top Shops

Ever wonder what sets Top Shops apart from the competition? Dive into their award-winning practices and explore behind-the-scenes strategies for operational excellence.

-

Job Shops Can’t Do Everything, And That’s OK

Deciding to narrow down its jobs and customers was a turning point for 2023 Top Shops Business Strategies honoree Manda Machine that has led to improvements in the front office and on the shop floor.

-

Benchmarking: An Invaluable Business Tool

Modern Machine Shop’s Top Shops program shows shops their strengths and opportunities for improvement, and provides recognition for high-performing businesses.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)