Share

Don Dumoulin (second from left), owner and CEO of Precise Tooling Solutions in Indiana, evaluates a mold built for a customer. “The shop is humming again,” he says. Photo: Precise Tooling Solutions

How important is the 25% tariff the United States recently reinstated on China-built injection mold tooling?

For Precise Tooling Solutions, this action by the federal government could not be more meaningful. Order activity is already making it clear that this will be a good year for the shop, whereas 2019 was not. By the middle of January 2020 — that is, just three weeks into this year — this Columbus, Indiana, mold builder with a staff of 40 had already booked more molds than it did for the entirety of 2019. Employees who might have grown accustomed to 40-hour weeks will now be called upon to work significant overtime. I spoke to owner and CEO Don Dumoulin about the change. How much of the upswing does he attribute to the tariff?

“All of it,” he says. The tariff went into effect during the final days of 2019. Since then, the shop has been hearing from mold buyers who had never been customers before — injection molders that, until that point, had been committed to sourcing their tooling from China.

2018 was a strong year for the shop, too. The tariff went into effect in July of that year. It was rescinded at the end of that year, and now recently restored, as the presidential administration apparently agreed with comments filed by 150 American mold builders on behalf of this action. Precise’s experience certainly demonstrates the effectiveness of the move. “The shop is humming again,” Mr. Dumoulin says. Meanwhile, he argues the tariff was also the right move.

A tariff is arbitrary, to be sure. This is one of its problems: It is a cost set by politics and bureaucracy rather than market forces and value. However, U.S. moldmakers have long struggled against arbitrary moves opposing them. Among these is the support foreign governments (China and others) give to their domestic toolmakers. By virtue of the tariff, the U.S. is now supporting its toolmakers as well.

The artificially lower cost overseas leads to another irrational factor, he says, which is the short-term actions of mold buyers. “U.S. businesses get caught up in cost savings that hurt their interests long-term,” he says. Molders saving cost by buying from foreign sources is particularly galling to him, he explains, because the mold frequently amounts to only 3-4% of the total cost of a plastic part. However, the loss of domestic moldmaking capability — a real possibility as significant amounts of mold work shift to China — would imperil plastics manufacturing. Since a new product made of plastic is defined by the mold, the ability to invent with plastics relies on access to moldmaking, and intellectual property is literally contained in the mold. If a tariff is “protectionism” — and it is — moldmaking is a capability arguably worth protecting, at least against artificial distortions.

Is 25% a fitting number? Again, arbitrary. But in this case, Mr. Dumoulin says that figure seems just right. U.S. molds are still costlier, but where the price difference compared to China used to be huge, the tariff now leaves the price of Precise’s molds generally within about 10-15%, he says. This gap is slight enough that the desire to buy domestically can close it. To many molders, the ease of proximity and the expectation of service, quality and delivery that come from sourcing from an American mold shop justify a reasonable price premium.

“Customers have always told us, if you can get the price within 20%, we will buy American,” he says. The tariff is now proving this to be true.

Related Content

How to Achieve Unmatched Accuracy in Very Large Workpieces

Dynamic Tool Corp. purchases two bridge-style double-column CNCs to increase the cutting envelope and maintain 5-micron cutting accuracy in the long term.

Read MoreFor This Machine Shop, Licensing Is the Answer to the Inventor’s Dilemma

Machine shops are natural inventors, but not necessarily suited to supporting and marketing a product. This Minnesota shop with an invention related to micromolding will share it through licensing.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

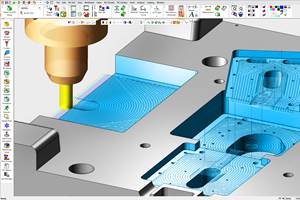

Read MoreCimatron's Updated CAD/CAM Software Streamlines Mold Design

Eastec 2023: Cimatron V16 includes a clean new user interface and increased automation for faster mold design, electrode creation and NC programming.

Read MoreRead Next

From Making Parts to Making Profits

New management layers bold, data-driven decision-making atop a legacy of moldmaking expertise.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More