Ball-End Tool Contours, Chamfers and Finishes in One Pass for Most Materials

The new IMCO Carbide Tool Pow•R•Arc end mill, to be shown at IMTS 2022, emphasizes speed. The cutter is able to run and increase feed rates to machine one’s mold up to five times faster than a four-flute tool.

Share

Autodesk, Inc.

Featured Content

View More

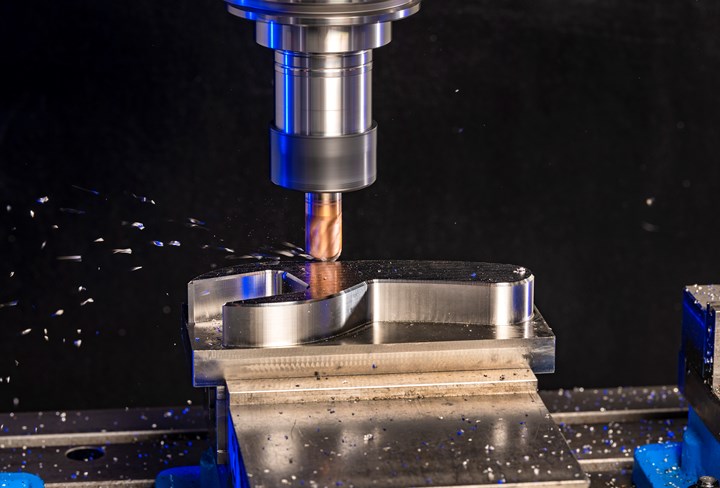

Pow•R•Arc A108 (¾" diameter, eight-flute ball end and 1" LOC) machines a 0.050" perimeter chamfer in 6AL-4V titanium. Compared with a four-flute tool, the Pow•R•Arc cutter leaves a bur-free finish at high speeds. Photo Credit: IMCO Carbide Tool

IMCO Carbide Tool launches the Pow•R•Arc ball-end cutter, the newest of IMCO’s high-performance cutting tools, at IMTS 2022. The company says its product is all about speed; the Pow•R•Arc is designed for contouring and chamfering at the fastest possible speed and feed rates in most materials, even cutting smoothly in workpieces with dissimilar materials, with no digs or handwork needed. Available with six or eight flutes, it is said to feature advanced geometries and a next-generation coating for faster feed rates, greater lubricity, reliable chip ejection and what is reported to be double the tool life over competitors’ tools tested.

When asked the single most important benefit of this technology for a mold builder, IMCO points to the large reduction in cycle time that it would take to machine one’s mold, the result of an end mill that is said can be run and increase feed rates up to 5x those of a four-flute tool. This means reduced cycle times, and increased profits because a moldmaker would be able to build more molds in the same amount of time, the company notes.

According to IMCO, the Pow•R•Arc cuts and finishes in one pass in hardened metals up to 62 HRC, aluminum, stainless steel, low carbon steel and super alloys such as high nickel alloys, cobalt chrome and titanium. It’s effective in both low-speed and high-speed machines, and it’s ideal for use in five-axis machines. The cutting tool can be ordered with long necks for working in deep pockets and easier maneuvering around mold guide pins.

Learn more about Pow•R•Arc IMTS booth #43-431522.

Related Content

-

Custom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

The Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

.png;maxWidth=300;quality=90)