Automating Thread Measurement

This automated, non-contact measurement system can eliminate operator errors when measuring UN series threads on thread gages and workpieces.

Share

ECi Software Solutions, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

Autodesk, Inc.

Featured Content

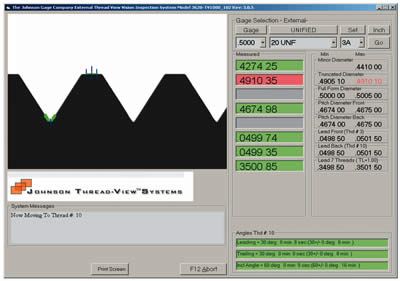

View MoreTraditional thread measuring procedures require operators who possess not only the skills to properly manipulate the measurement equipment, but also the experience to correctly interpret the results. Different operators can come up with different findings, depending on the measuring method. Johnson Thread-View Systems, LLC (Bloomfield, Connecticut) has developed what it says is the only automated, non-contact measurement system that, in 3 minutes, can measure all 11 ASME-required thread parameters to 0.5 micron accuracy. Its Thread-View system aims to remove the potential for introducing human error when measuring UN series threads on thread gages and workpieces.

The heart of the system is a collimated LED light source, which the company has found provides good beam accuracy despite fluctuations in temperature, humidity or other environmental conditions. This stability is critical when measuring to one millionth of an inch as required for thread gages.

An operator needs only to mount a thread gage or workpiece in the system’s fixture and enter basic thread specifications into the system’s software. This information includes thread size, pitch and class. In operation, the focused light source travels across the threads and continues to a mirror that directs the thread profile to a microscope camera assembly. The camera captures a high-resolution image of the thread profile and sends it to the Thread-View software for analysis. The software calculates the various thread parameters and prints a NIST-traceable calibration report. The thread parameters measured include major, minor and pitch diameters; leading and trailing angles; included angle; lead; lead over several threads; and root radius (for UNJ series threads).

Special fixtures are available to hold threaded workpieces. When inspecting threads on a workpiece, an operator enters the part’s length, as well as starting and ending measurement points. The system can measure as many threads as necessary. Minimum workpiece diameter is 0.06 inch; maximum is 4 inches. The system can measure parts as long as 6 inches, though the company is working to increase this capacity to allow measurement of longer workpieces.

Related Content

-

The Link Between CNC Process Control and Powertrain Warranties

Ever since inventing the touch-trigger probe in 1972, Sir David McMurtry and his company Renishaw have been focused on achieving process control over its own manufacturing operations. That journey has had sweeping consequences for manufacturing at large.

-

How to Evaluate Measurement Uncertainty

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

-

Rethink Quality Control to Increase Productivity, Decrease Scrap

Verifying parts is essential to documenting quality, and there are a few best practices that can make the quality control process more efficient.

.jpg;maxWidth=300;quality=90)