At a Grand Opening, Sodick Reveals More Than New Machines

Along with launching a new line of hybrid machines, the EDM manufacturer is tailoring one of its EDM models specifically for post processing additive parts.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View MoreSodick’s grand opening for its new North American headquarters in Schaumburg, Illinois, offered ceremonial flourishes fitting for a company that has regard for its cultural traditions and Japanese roots. After the event opened with remarks from Sodick Inc. President Yuji Akutsu and a ribbon-cutting ceremony with the city’s mayor, spirits were lifted by a traditional sake ceremony (kagami-biraki) that commenced with the wallop of a wooden mallet upon the sake barrel’s lid.

For Sodick, there was plenty of reason to celebrate. The company’s new North American headquarters is impressively modern. The 40,000-square-foot building is decked out in the company’s signature white and green with plenty of natural light shining on a $5 million inventory of spare parts. But out of view was something just as important to Sodick: a new strategy that melds the company’s core business—EDM—with its growing investment in additive and hybrid technologies.

The highlight of the grand opening itself may have been the company’s new additive technology center and the two machines housed within it: the OPM250L and the OPM350L hybrid metal 3D printers. At the very least, these machines represent an acknowledgement of additive and hybrid manufacturing’s rising significance to Sodick, a company so dedicated to EDM that it produces more than 80 percent of its machine parts in house across three countries.

Clearly, EDM and metal additive manufacturing (AM) have been complementary technologies for years, especially wire EDM’s application for cutting AM parts away from build plates. That hasn’t gone unnoticed by this manufacturer of EDM equipment, which launched its first hybrid metal AM printer, the OPM250L, two years ago at the International Manufacturing Technology Show (IMTS). The direct metal laser sintering (DMLS) powder bed printer combines a 500-W ytterbium laser with a 45,000-rpm linear motor spindle, which can perform milling operations during pauses in the printing process that allow access to internal features that otherwise would be inaccessible when the part is finished.

Since the OPM250L’s launch nearly two years ago, Sodick has focused on technology and capacity upgrades to its OPM hybrid product line. Last year, the company introduced its parallel mode technology, which optimized the machine’s 500-W laser path by allowing it to target four points simultaneously within a build. All programming takes place offline on Sodick’s dedicated CAM software that controls both sintering and three-axis milling operations, including cutting tool changes. If a tool breaks or the part becomes out of a specified tolerance during a milling operation, the software detects those conditions and instructs the machine to replace the broken tool with a sister tool for remachining.

Since the OPM250L’s launch, the OPM line has expanded to include the OPM350L, a larger-capacity hybrid machine that includes Sodick’s materials recovery system (MRS) unit. This system, which comes standard with the OPM350L and is available as an option for the OPM250L, automatically delivers powder into the OPM’s material feeder for use in the additive manufacturing process. As excess powder is delivered to the OPM’s powder receptacle, the MRS unit conveys this material back for sieving and return to the OPM material feeder. By continually recycling powder, Sodick says that the MRS unit allows the OPM to run continuously for up to a week using just 30 kg of material.

Sodick’s ongoing commitment to additive manufacturing via the OPM line doesn’t mean the company is any less committed to its core business. At the North American headquarters’ grand opening, the company also unveiled two EDM models out on the main floor.

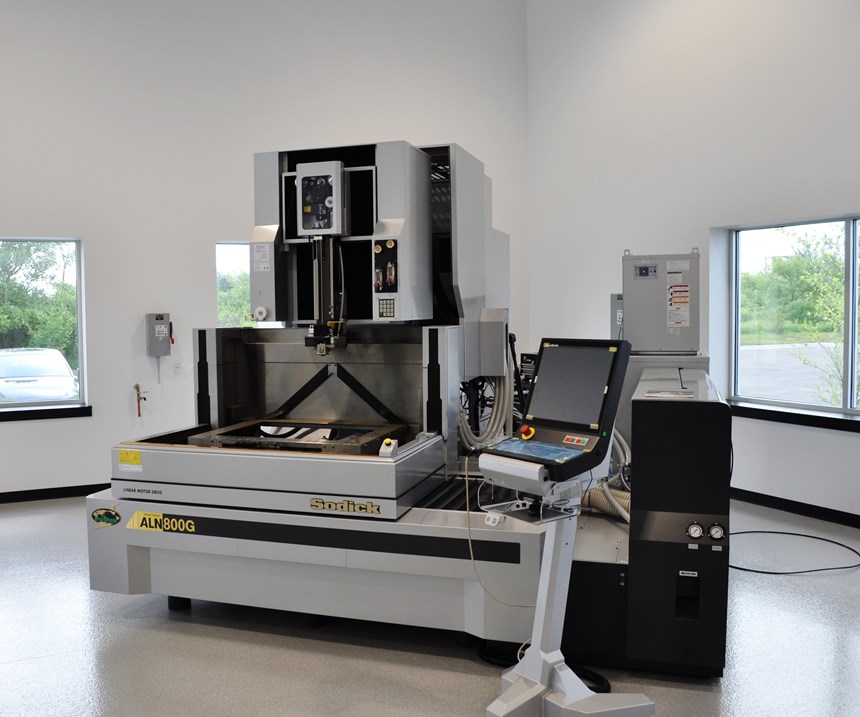

The ALN800G wire EDM, which Sodick says is the largest drop-tank EDM model in the world, is designed to accommodate workpieces large enough to require the use of a crane. While EDM models with a front drop door limit an operator’s access to the work area, the drop tank makes the entire work area accessible. Sodick says that the ALN800G also has a high-column option available that makes it the tallest wire EDM on the market, with an 800-mm (31.5-inch) Z axis, versus a standard Z axis of 500 mm (19.7 inches).

The other machine receiving its first public showing, the VL600QH wire EDM, is a high-column economy EDM specifically targeted at the additive industry. Evan Syverson, Sodick’s additive business development manager, told me that Sodick’s ability to serve post-processing needs for additive is a key business strategy for the company moving forward. “As additive companies keep expanding the capacity of their DMLS machines, users must also make sure that their post-processing equipment is keeping pace,” he says. Because of that, the demands of additive applications are a bit different than most EDM work. Baseplate and support cutoff doesn’t necessarily require the extreme precision in which EDMs can excel. What it does require, however, is a tall Z axis that can accommodate the ever-growing size of 3D printer baseplates.

Mr. Syverson added that a high column typically demands investment in a advanced wire EDM model. Thus, there is a significant cost to end-users who are not only paying for a high-column option, but who are also paying for many capabilities not actually needed in processing AM parts. This is why Sodick is marketing the VL600QH as an economy high-column EDM—a trend likely to continue as machine tool builders recognize the unique post-processing needs that additive parts require.

All the machines mentioned above will be at Sodick’s booth at IMTS.

Related Content

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)