Are Your Operators Race Car Drivers or Pit Crew?

If machine operators act more like the latter, always stopping to “change the tires,” you might want to take another look at the cleanliness and organization of your facility.

Share

Toolcraft, a contract machine shop near Seattle, Washington, operates a lot differently since achieving ISO 9001:2008 certification in 2012. “It’s helped us become a lot more process-based,” says Operations Manager Steve Wittenberg about how much things have changed in 5 years. Advice like “Go and ask Joe” is now less common when questions arise, he explains. Rather, the company has built previously “tribal” knowledge into the process.

ISO certification has also helped to ensure everyone always has everything they need, albeit in an indirect way. The work of scrutinizing and documenting processes and procedures inspired a new vision among the shop’s leadership: a laboratory-like environment that would better reflect its more scientific approach. Everything would have its place, and there’d be little room for activities detrimental to spindle uptime, whether searching for a needed tool or leaving one’s station to ask a question. To that end, the Toolcraft crew set about cleaning and reorganizing the entire facility, a task that involved everything from rearranging the machinery layout to conducting targeted 5S exercises to upgrading the air-filtration system.

Although the shop looks more like a lab than ever before, another analogy is a better fit for illustrating the benefits of these reforms:

“Our machinists are a lot like race car drivers,” Mr. Wittenberg explains. “You never see a NASCAR driver jump out and change the tires. In the same way, machinists need to have work orders in the right place at the right time. Raw material should be in the right place at the right time. All needed cutting tools should be loaded and ready to go. There shouldn’t be any running around ‘changing the tires,’ if you will.”

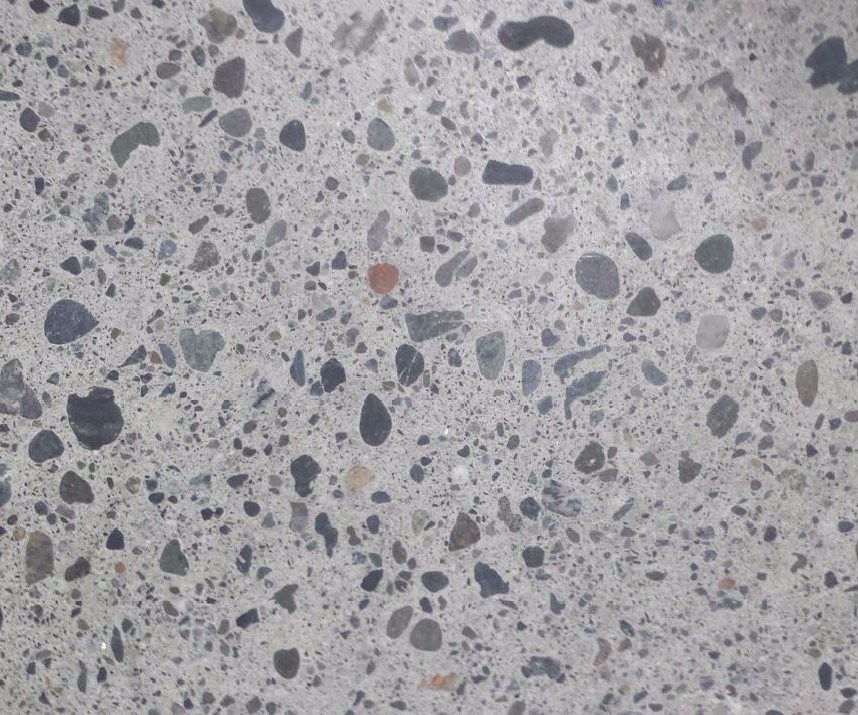

Some of the activities associated with cleaning and organizing the facility have a more direct impact on production than others. It’s easy to see the results of, say, organizing and standardizing the tooling at individual workstations; changing all the lights in the shop (a 45-percent improvement in energy efficiency); or even moving from a single air-filtration unit to a seven-unit system (assembly is reportedly easier because less grime accumulates on the parts). On the other hand, painting the walls didn’t directly impact efficiency or productivity. Polishing the floor makes it easier to clean and reportedly makes dropped tools easier to find, but such gains are difficult to link directly to the bottom line. And yet, such changes have been highly prioritized anyway.

An unmotivated driver isn’t likely to run a good race, Mr. Wittenberg explains. Less humid air helps to keep the crew more comfortable—and happier—on the shop floor. Cleaner, shinier floors and a fresh coat of paint not only make the facility more attractive and sophisticated to visiting customers, but help to instill pride in the work—pride that might also impact outsiders’ first impressions. “It’s hard to quantify a return on improved morale,” Mr. Wittenberg says, but such intangibles are important for Toolcraft all the same.

Just as race car drivers aren’t likely to be replaced by unfeeling robots anytime soon, manufacturing will likely always involve people to some extent. That’s regardless of the ongoing march toward greater automation (for its part, Toolcraft is considering the addition of machine-tending robots, having only recently installed its first multi-axis turning center and, a few years before that, its first horizontal machining center). In Toolcraft’s view, a clean and organized facility can not only ensure shopfloor personnel act more like drivers than pit crew, but also put those drivers in a competitive frame of mind.

Read Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=300;quality=90)