December 2023 Issue

December 2023

Digital Edition

Features

Featured articles from the December 2023 issue of Modern Machine Shop

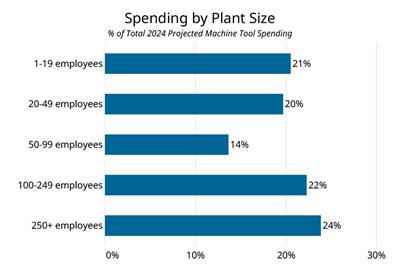

Large Plants Plan High Rates of Capital Spending in 2024

Gardner Business Media’s Capital Spending survey projects a modest decline of 7.4% in machine tool spending next year. While job shops are taking a wait-and-see posture, large plants plan robust spending with machining centers leading the way.

Read More

Random Thoughts on Manufacturing, Innovation, What We Appreciate, and More

Here are several mini-columns merged into one. Take these thoughts all at once or in small doses.

Read More

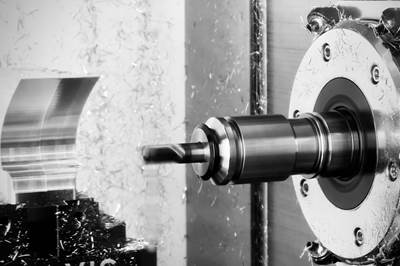

How Important is Spindle Power?

Consider these spindle attributes to make a choice that is balanced, usable and compliments your processes as best as possible.

Read More

An Open Letter to Kids About Machines and the World of Making Things

This is an open letter to middle- and high-school students about choices they’ll soon face. It is also an introduction to Career and Technical Education (CTE), the world of CNC machining, and a reminder that there are options outside of the traditional four-year college path.

Read More

Metalworking Activity Continues its Roller Coaster Year of Contraction

October marks a full year of metalworking activity contracting, barring just one isolated month of reprieve in February.

Read More

5 Benefits of Having a Manageable Backlog

Shops must effectively deal with workloads and not let the backlog grow too large in order to keep customers satisfied.

Read More

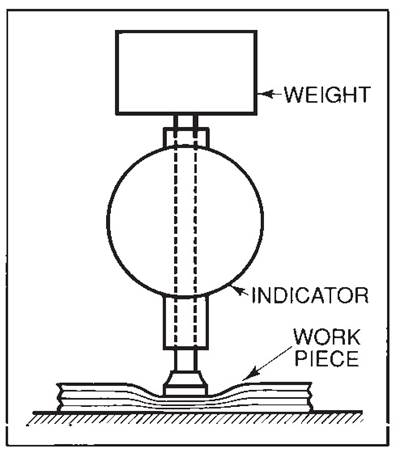

The Many Ways of Measuring Thickness

While it may seem to be a straightforward check, there are many approaches to measuring thickness that are determined by the requirements of the part.

Read More

Controlling Extreme Cutting Conditions in Large-Part Machining

Newly patented technologies for controlling chatter and vibration during milling, turning and boring operations promise to drastically reduce production time and increase machining performance.

Read More

The Keys to Combining High- and Low-Volume Production

Process expertise and precise production planning enable the Kinetic Company to produce both high- and low-volume jobs requiring machining, grinding, heat treatment and other processes.

Read More

Combining Functions With User-Defined G & M Codes

CNC programmers gain flexibility when using custom macros to define G and M codes themselves.

Read More

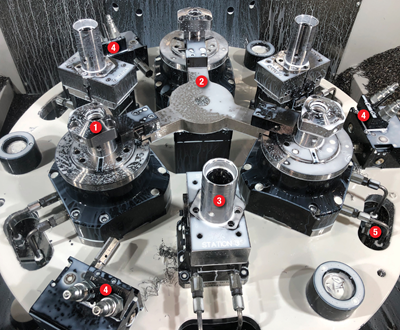

Machining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read More

.jpg;maxWidth=300;quality=90)