An Insider’s Look at MTConnect-Enabled Applications

A new whitepaper from the MTConnect Institute is designed to help software developers create client applications that take advantage of the valuable data generated by manufacturing equipment but previously more difficult to access.

Share

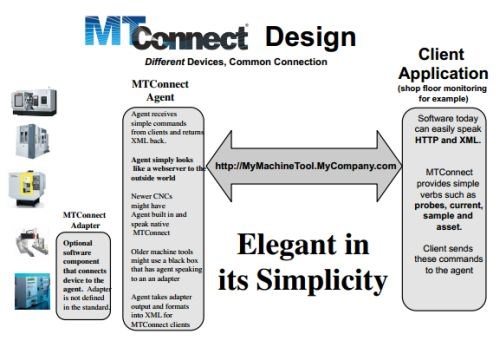

The whitepaper photo above depicts the Three As of MTConnect:

agents, adapters and applications.

MTConnect is an open and royalty-free standard for manufacturing that is connecting manufacturing equipment with applications by using proven Internet protocols. But MTConnect is not an application. Applications are software products designed to use data in the specified MTConnect format for such purposes as machine monitoring, energy usage management, cutting tool control and many others. A new whitepaper from the MTConnect Institute is designed to help software developers create applications that take advantage of the valuable data generated by manufacturing equipment that was more difficult to access before MTConnect appeared.

Although the content of this whitepaper is rather technical and thorough, it is readable and well-organized, so any shop interested in what MTConnect can do to improve operations ought to check it out for its insights into the inner workings of useful applications. The paper includes an overview of MTConnect, definitions of key terms, illustrations of essential concepts and basic outlines of application architecture. The whitepaper is available here.

Related Content

-

Give Job Shop Digitalization a Customer Focus

Implementing the integrated digital technologies and automation that enhance the customer's experience should be a priority for job shops and contract manufacturers.

-

Process Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

-

Shop Quotes Smarter, Works Harder with Machine Monitoring

Temco first installed MT-LINKi to optimize quoting. Now, the software helps the shop optimize its machines — and machine purchases.

.jpg;maxWidth=300;quality=90)