An Alternate Micromachining Process for Composites

This process combines sandblasting and photolithography to enable fast machining of multiple, accurate features into composites.

Share

Machining composites with conventional machine tools is challenging largely because composites have properties that require special approaches to milling and drilling. They are highly abrasive, meaning cutting tool life can be very low. Plus, the low-thermal-conductivity materials do not produce sizeable chips that carry heat away from a workpiece during machining. Thus, the wrong tool (or a worn one) can cause the material’s resin to burn or melt. Delamination and splintering are also issues given the material’s structure, which consists of resin-bound fibrous layers. In addition, cycle times for workpieces that require multiple machined features can be lengthy because milling and drilling operations create just one feature at a time. That means tooling costs can be high, too, especially when the part requires holes with many different diameters.

Waterjet is an option that provides more flexibility to do a variety of hole shapes and sizes, but the process still can lead to delamination. However, another versatile alternative, Photo-Machining, is now available to enable burr-free machining of composite parts that require multiple small features. The process was developed by Ikonics Micro Machining Solutions, a manufacturer located in Duluth, Minnesota.

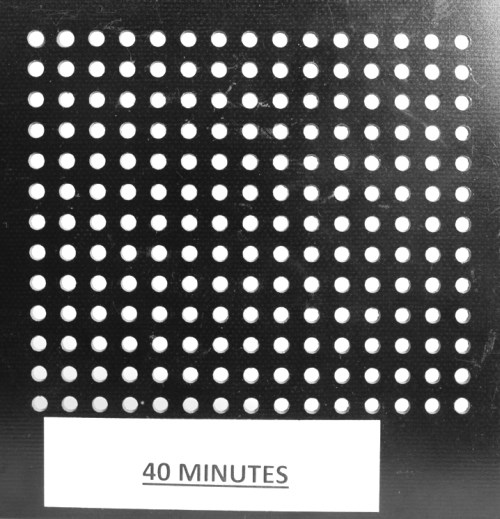

Although it’s not a complete replacement for any of the aforementioned composites machining methods, Photo-Machining can effectively produce multiple perforations, blind holes, cavities and other features simultaneously over large surface areas. This includes array patterns with numerous holes, such as those found in blocker doors for jet engines. In fact, the company says its process can reduce production time for some applications by as much as 75 percent compared to conventional machining processes.

The Photo-Machining process melds two existing technologies—sandblasting and photolithography—to enable the machining of features into various types of composite materials. The process starts with the creation of a protective mask via photolithography with “windows” of all the features required for the part. Users simply email the feature pattern artwork to Ikonics, which, in turn, photo-processes the pattern to create the sandblast-resistant mask in a proprietary, photo-reactive film. After receiving the self-adhesive mask, the user applies it to the surface of the composite part and the features are created via sandblasting. After sandblasting, the mask is removed from the part to reveal the precisely machined features.

Photo-Machining offers a resolution of 200 microns, making it possible to machine highly accurate small holes and geometric features with fine details. It is especially effective for acoustic and other industrial applications in which a specific hole pattern, size, depth or design is required. The inherent nature of sand blasting produces a taper in the perforated hole. The angle of this taper ranges from 0.5 to 15 degrees depending on the hole diameter, the material and the part’s thickness. This means the entry hole diameter will be larger than the exit hole (the process is limited to a maximum thickness-to-hole diameter ratio of 2:1). However, the company points out that theoretical research suggests such a taper may be helpful for some acoustic applications because it enhances sound attenuation.

Because the mask has a finite life before degrading, machining depth is limited. Attainable hole depth also depends on the fiber and resin materials as well as the types of features being machined. In general, the Photo-Machining process is suited for composites as thick as 5 mm. It offers diameter size accuracy and repeatability for through holes to within ±50 microns.

According to the company, the dry Photo-Machining process doesn’t burn or delaminate composite workpieces, and it doesn’t create burrs that must be removed via secondary operations. In fact, the sand blasting process actually smoothes the hole surface as it perforates the material. Tooling and setup costs are minimal, too. Because multiple holes are created simultaneously, throughput (therefore overall machining cost) is not a function of the number of holes or features required for a part. Plus, the masks can be created rapidly, so design or pattern changes can be made quickly and inexpensively.

In addition to mask creation, the company can also provide automated sandblasting equipment and abrasive media for a turnkey solution to ensure the process delivers a uniform cutting rate and maintains a consistent nozzle distance away from the workpiece. The company also offers material testing to help dial-in the process for a given material as well as complete contract machining services at its Duluth facility.

Read Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)