An Alternate Contract Machining Business Model

The Future of Machining - 2005 The number of shops that will not communicate with or even know their customers will increase.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

How some manufacturers and their machine shop vendors interact will change. It may be that shops won't even know their customers by name, and vice versa.

The way some manufacturers design components, obtain machining quotes and order parts for their products will change in the next 5 or so years. A newly designed business model is likely to soon catch traction, offering with it not only a streamlined procedure for OEMs to get their parts, but also a potential steady work stream for a variety of job shops.

Enter the online machine shop.

In ordering parts from an online machine shop, there is a chance that a manufacturer will never directly communicate with the shop that actually produces its parts. In fact, the manufacturer may not even know the name of said shop. All processes that go into part production, including secondary and finishing operations, will be transparently handled and managed by the online machine shop.

Prediction:

The number of shops that will not communicate with or even know their customers will increase.

The simplicity of the online ordering process will benefit both manufacturers and existing machine shops. A manufacturer, one that might never have dealt directly with a bricks-and-mortar machine shop, can develop a part design and obtain a nearly instant job quote online, eliminating logistics and multiple-vendor headaches common to the traditional quoting routine. (Parts will be ordered and received directly from the online shop.) As online shops grow, they will need additional support from "traditional" machine shops, offering another avenue for those shops to gain new work.

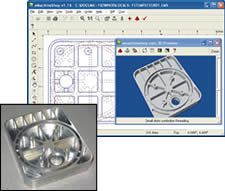

One early adopter of this alternate online business model is the eMachineShop (www.eMachineShop.com), led by its president, Jim Lewis. The foundation of this online machine shop is its proprietary 3D CAD and quote-generating software, which manufacturers download at no cost. Though this is the only software eMachineShop supports, the software was designed so that even those with no CAD experience could quickly ramp up. During part design, the software will provide feedback to the designer by flagging possible problems. Once the design is completed, the software's quote generator will consider part geometry, material and a variety of other parameters and, in a matter of minutes, automatically provide a price quote and delivery date. If all is acceptable to the customer, the parts can be ordered with a few mouse clicks.

At this point, the job is assigned to one of eMachineShop's partnering vendors. The online shop currently has in its stable shops that offer CNC machining, fabrication, EDM, casting, injection molding, extrusion and thermoforming processes. This list is likely to expand. So, too, will the opportunities for more jobs shops to become suppliers to online shops.

Existing shops must first not only recognize the potential that this new business model offers, but also be open to accepting it. To partner with such online shops will require quality, reliable delivery and competitive pricing. According to Mr. Lewis, the ideal partnering vendor to an online machine shop is one that is relatively small, yet managed well enough to keep a good quantity of small- to medium-run orders on schedule.

One possible hurdle that online shops may face relates to confidentiality, given the inherent disconnect between the manufacturer and the shop that produces its parts. Mr. Lewis indicated that after detailing its confidentiality policy, eMachineShop has had few concerns from customers about privacy. Still, some manufacturers may want to have face-to-face contact with the vendors that make their parts.

Manufacturers may also be leery about repeatable quality on repeat jobs, because the shop that machined that first batch may not machine the next one. In such cases, eMachineShop allows manufacturers to specify that the shop which produced the first batch of parts produces successive batches.

Is this the model that the big captive shops will use to obtain their parts? Maybe not. However, it may change the way many manufacturing companies think about developing prototypes or obtaining small- to medium-sized batches of parts. It likely will also change the way that existing machine shops think about how to bring new work in house.

Read Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=300;quality=90)