Amerimold 2016: Positive Vibes, Sophisticated Technology

Moldmakers reported good business and optimism for the future amidst displays of technology ranging from modular workholding to new machine tools to non-contact measurement.

Share

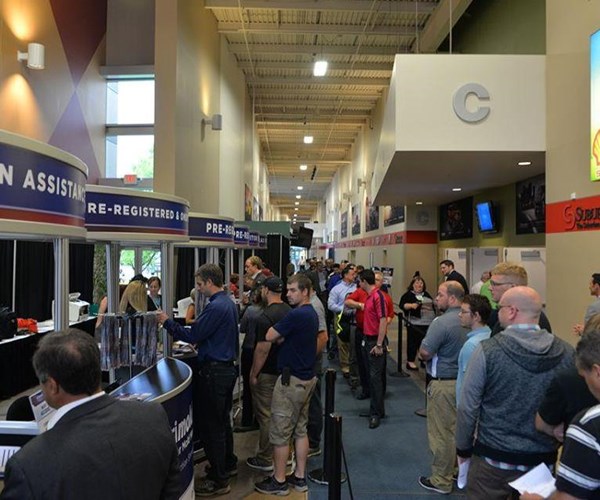

Attendees line up at the opening of the Amerimold Show. A minor glitch—a power outage that slightly delayed the opening—didn’t seem to dampen anyone’s spirits.

Walking out of the Amerimold show at closing time on the first day, I was struck by the fact that plenty of conversations were still happening at booths in all corners of the hall. As a veteran of plenty of trade shows, I’d have expected traffic to drop far more markedly and far more quickly in the waning hours of the event, even on the first day.

Perhaps everyone was simply waiting around for the subsequent MoldMaking Technology “Leadtime Leader” awards presentation and overview of the always-humorous “Top 10 Reasons to be a Moldmaker,” not to mention the Casino-themed after-party. Regardless, the mood was overwhelmingly positive among the attendees and exhibitors that I had a chance to engage at the Amerimold 2016, hosted June 15-16 at the Suburban Collection Showplace in Novi, Michigan. And, there were more of both compared to last year’s edition of the show, with 3,000 registrants versus 2,700 and a record 197 exhibitors.

Somewhat unusually for the manufacturing trade show landscape, those exhibitors include not just technology suppliers, but also a large number of end-user shops (28, to be exact). Many of these mold manufacturers indicated that tool programs they’ve been waiting for, particularly in the automotive industry, have already or will soon be released, and that they expect at least steady business through 2017.

Highlighting just how competitive this sector is, capability to build quality tooling doesn’t seem to be enough for some of these shops. Across the sector, recent years have seen many add to design/engineering services on the front end of build, and, particularly, tool sampling on the back end. The Amerimold show has transitioned right along with them. This year, the technical conference program added an injection molding-focused track to the typical engineer, build and maintain topics. The show was also co-located with the Thermoplastic Composites Conference for Automotive (TCC Auto), which focuses on automotive light-weighting.

Still, this expanded focus did nothing to diminish Amerimold’s role as a showcase of technology that moldmakers rely on to cut cores and cavities from hardened steel—technology with potential applications that go far beyond moldmaking. This slideshow features a number of examples, including modular, quick-change workholding, cutting tools for long reaches and other difficult conditions, non-contact metrology and more.

.png;maxWidth=300;quality=90)