Adopting a Growth Mindset for Additive Manufacturing

Failures can help us learn, especially in the case of additive manufacturing. Breaking down psychological barriers like fear of failure can help AM users succeed.

Share

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Efforts like the Additive Manufacturing: Why the Failure? (#AMWTF) series on LinkedIn are helping to destigmatize build failures and foster a growth mindset for the AM community.

With all the talk of build failures, flaws and defects, it is easy to see why people can get scared of using additive manufacturing (AM), and metal AM in particular. Keyholing, lack of fusion, gas porosity, delamination, recoater crashes… the list goes on and on, and we academics only tend to make it worse. Why? Because these failures help us justify the research and experimental work needed to understand the problem and mitigate the associated risk. The outcome and intentions are good, but I am starting to worry that we have only exacerbated people’s fears, not cultivated the growth mindset that is needed to overcome them.

I am just as guilty of this as anyone else. In fact, I gave an entire day-long workshop to a group of senior engineers who wanted to know everything that could go wrong with the metal AM used on their medical implants. Their goal was to understand what questions they needed to ask their engineering staff to make sure that things did not fail, and it was one of the most fun workshops that I have ever done in a company. Unfortunately, by the end of the workshops, even I was asking myself why the heck would I ever want to use AM given everything I had just learned. Needless to say, I have never offered that particular workshop again, and I make sure to provide at least one solution to mitigate each risk whenever failures are discussed.

At the same time, one of the best ways to learn is through failure — something that many people fear or don’t want to admit happened to them. It is referred to as “productive failure,” but as an academic, I have a hard time publishing a paper on anything that fails. Journals (and peer reviewers, in particular) only want to know what works and what improvements have been made; they don’t want to publish all of the false starts or mistakes along the way.

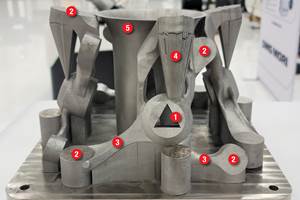

This is what motivated me to launch Additive Manufacturing: Why The Failure? (#AMTWF) with Peter Zelinski — the editor-in-chief of Additive Manufacturing and Modern Machine Shop — this past spring. Each month, we share one of the build failures from CIMP-3D, the metal AM center that I co-direct at Penn State. As each failure is revealed, anyone can comment on why they thought the build failed or pose questions to help them ascertain why the failure occurred. I then respond to each comment, revealing additional information and, occasionally, another image of the failure. Eventually, the discussion tapers off, and Pete and I videotape an explanation of why the failure occurred, incorporating comments posted on LinkedIn into our discussion. We also make sure to discuss how this failure could be avoided or mitigated in future builds.

Our #AMWTF series seems to have struck a chord within the AM community (or at least those of us online) as the response to each posting surpassed our expectations. We quickly picked up a steady online following from both industry and academia, and new participants would join as we posted each new failure. The interactive nature of the “comment-reply-comment” kept everyone engaged, and a dialogue emerged online that began to destigmatize AM build failures, alleviating some the shame or disgrace that can be associated with a failure.

Granted, no one wants to fail, but AM is still so new that users will invariably fail along the way as they push the limits of their capabilities or try something new with an AM process. As an AM engineer and designer, I am constantly asking, ‘How do we make this wall thinner? Do we really need support structures on this overhang? Is this bridging distance too much?’ Or even more unorthodox questions about intentional porosity or leaving trapped powder inside a structure.

The list of questions goes on and on and on, and you never know what idea or innovation a crazy question will trigger — or what a build failure will reveal. If users are afraid to face their fears and come at AM with a fixed mindset, then you can imagine how difficult it will be to fully embrace AM and enjoy its benefits. Unfortunately, the situation can be even more daunting in an organization where “failure is not an option,” as the associated culture and risk tolerance will invariably stymie AM adoption from the start.

This is where a growth mindset is essential for AM right now. Individuals need to be willing to embrace new challenges, take risks and persevere in the face of failure — without the fear of humiliation. Granted, we do not want AM parts that fail in use, but organizations need to create psychologically safe environments where people can be creative and explore AM so that they get it right. This is easier said than done, and not something that changes overnight. It takes time, commitment and resources to overcome not only the technical challenges associated with AM but also the psychological barriers individuals and organizations will face when trying to displace well-established manufacturing methods with AM.

AM is hard, but don’t let the fear of failure hold you back. More and more companies are figuring it out, and you have to be open and willing to take risks and face your fears to make it happen. Otherwise, you will find yourself (and your company) left behind with a fixed mindset that failed to achieve the benefits that others are finding.

Related Content

The Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D printed parts.

Read MoreThe Cool Parts Showcase Seeks Innovative 3D Printed Parts

Do you solve problems with 3D printing? Enter your 3D printed parts in this contest from The Cool Parts Show.

Read MoreDigitalization and Done-In-One Reign Supreme at BIEMH 2024

European manufacturers may have a different balance of markets than their U.S. counterparts, but the practical challenges they must overcome are often similar — as are the solutions.

Read MoreDesigning a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More