Share

A new tool offers a fundamentally different method for forming internal threads in aluminum and other lightweight alloys. Emuge Corp. developed the Punch Tap in conjunction with Audi, which held exclusive rights to its use in the automotive industry until its wide-market debut at the International Manufacturing Technology Show (IMTS) 2018. While other threading techniques slowly enter and exit the hole to avoid damaging the threads, the Punch Tap is designed for quickly plunging into the material to thread depth, cold-forming the threads with a single twist and exiting—all in a fraction of the time it takes to using a traditional tap, cold-forming tap or a thread mill. Thanks to its atypical geometry, it can move quickly without damaging the threads it forms.

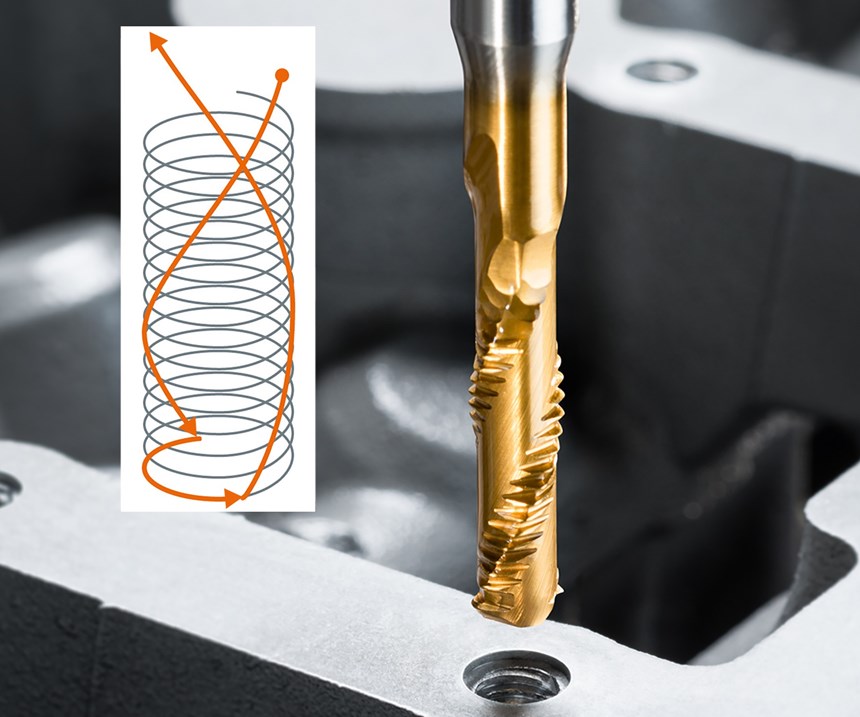

The tool has two helical rows of flutes with thread-forming teeth, offset 180 degrees from each other, traveling down the length of the tool. Two pilot edges, one at the tip of each flute, create two helical clearance grooves for the flutes to follow. These grooves ensure the thread-forming teeth do not touch the interior wall as the tool rotates clockwise into the hole. Once the tool reaches full depth, it stops, then rotates 180 degrees counterclockwise. Only then do the teeth contact the hole wall to cold-form all of the threads. After the 180-degree rotation, the rows of flutes are aligned with the clearance grooves opposite of those they followed plunging into the hole. The tool continues a counterclockwise rotation as it exits the hole to keep the flutes inside the helical clearance grooves. After the Punch Tap exits the hole, the clearance grooves remain, but are said to have a negligible effect on thread function. (The process is demonstrated in this video.)

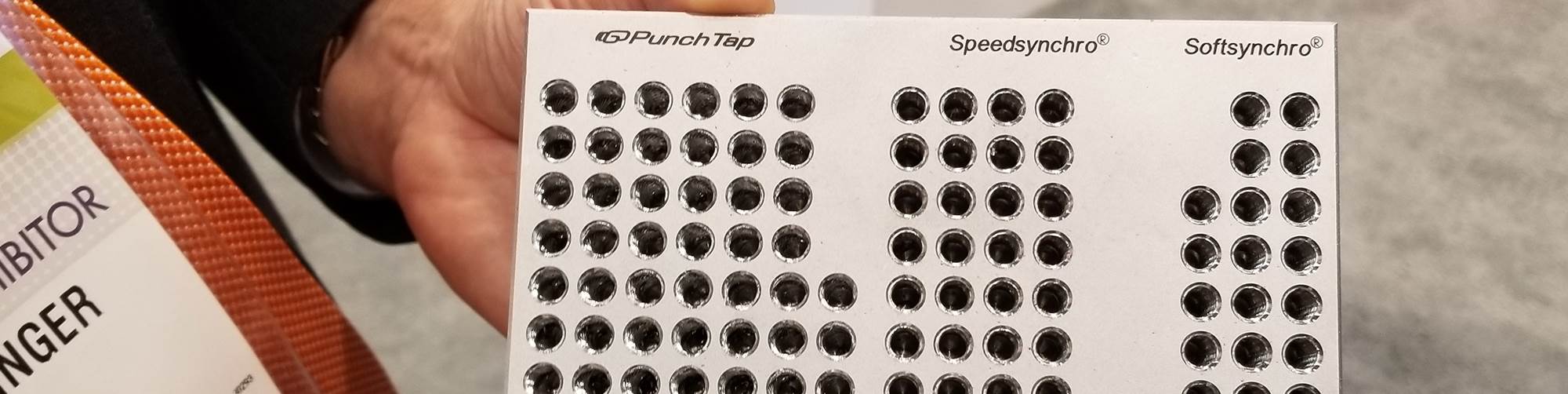

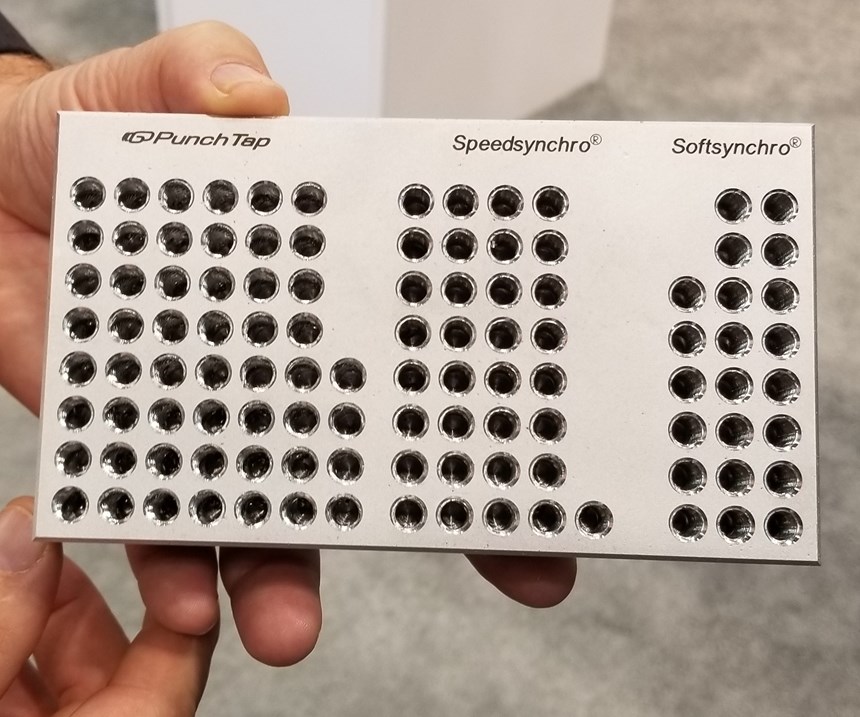

The company says this tool can improve hole-threading speed by 75 percent compared to conventional and cold-forming taps, which require precise rotation to prevent damage to the newly created threads as the tool exits the hole. In demonstrations at this year’s IMTS, the Punch Tap took less than half a second to completely thread and exit a hole in an aluminum workpiece. This speed can translate into substantial time savings for any manufacturer needing to thread large numbers of holes in lightweight metal parts.

Unlike many tools, the Punch Tap is only available as a customized product. “It is an engineered product that has design features which are application-specific to an end-user’s component design and material composition,” says Emuge Product Director Mark Hatch. He says the company will work with customers to perform detailed analysis and adjustments, depending on a broad range of technical issues.

The Punch Tap requires a specialized toolholder called the PT Synchro. This holder provides force-locked rigid clamping via a cylindrical ER collet that enables high torque and reduces the stress on the tool. The standard surface treatment is a TIN-T26 coating, and it forms threads in sizes ranging from #8 through 5/16.

The tool is unsuitable for metals much stronger than aluminum, both because it creates threads via cold forming and because the cutting edges that produce the entry grooves can take only a limited amount of shearing force. Additionally, the plunging motion of the tool path requires a the manufacturer use a CNC machine with a control capable of performing the specialized Punch Tap cycle, currently available in the latest generations of Heidenhain, Siemens and FANUC controls.

Related Content

Selecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreHow to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreForm Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

Read MoreToolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=300;quality=90)