A Smooth Transition to Five-Axis Machining

A mold manufacturer that specializes in precision, thin-walled container molds chose an integrated approach to establishing an effective five-axis “3 + 2” machining process.

Share

Takumi USA

Featured Content

View More

Every machine shop that adopts a new equipment platform faces an inherent learning curve. That’s why it’s not surprising that Steve Nadeau, general director of Canada’s Moulexpert, was cautioned by some of his shopfloor employees that it might take a bit of time to get any real production out of the company’s first five-axis machine. But as it turns out, the injection mold manufacturer located in Levis, Quebec, was running jobs on its new five-axis machine a mere two and a half weeks after it was delivered.

After years rebuilding molds for customers producing thin-walled containers for food and other consumer products, Moulexpert now uses its five-axis machining capability to manufacture precision, thin-wall container molds of its own design. The machine recently installed in the center of its facility enables the company to speed delivery times of those competitively priced molds.

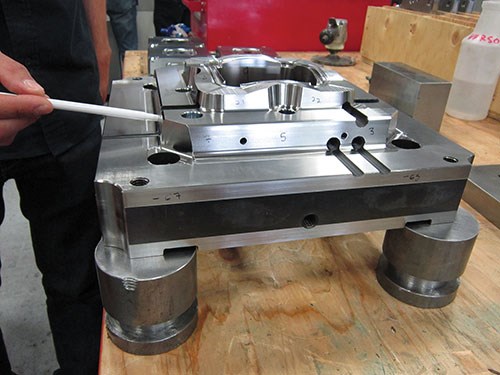

The company doesn’t use its new machine to perform full-five-axis contouring operations, however. Instead, it finds great value in five-axis positioning, or “3 + 2” machining, whereby a three-axis milling program is executed with the cutting tool locked in a tilted position made possible by the machine’s rotational A and C axes. This technique is especially helpful for drilling cooling holes in the thin-wall container mold inserts that parallel the angled walls of the insert cores and cavities. Unlike holes drilled normal to an insert’s parting line surface, angled holes provide more effective cooling, resulting in a faster, more consistent injection molding process.

However, drilling these holes on a conventional three-axis machine requires insert blocks to be refixtured multiple times. The 3 + 2 approach allays this problem, because the additional rotational axes enable the tool to approach five faces of a block at virtually any angle in one setup. Plus, 3 + 2 makes it possible to use short, rigid cutting tools because the spindle can be positioned closer to the workpiece. Shorter tools permit faster feeds and speeds with less tool deflection.

I recently met with Mr. Nadeau and Marc De Grandmont, company project manager, who outlined how the company established a five-axis process that best suited its particular needs. The men also revealed how the support and advice they received from their equipment and software providers helped streamline the integration of five-axis machining into their shop.

Three-Axis Limitations, Five-Axis Alternatives

Moulexpert opened in 2001. It’s a modest-sized operation with 20 employees, but Mr. Nadeau says that manageable size gives it the nimbleness to more quickly respond to customers’ special requests. Most employees have been with company for many years as well as with other mold makers, so there’s a great deal of collective machining and moldmaking experience, especially with thin-walled containers.

When the decision was made in 2012 to focus on designing and manufacturing its own thin-wall container molds, it was clear that the company’s three-axis equipment would hamstring its efforts to produce quality molds effectively. This was largely due to the number of angled holes that these molds’ inserts require not only for cooling, but also for venting and hydraulic circuits. The number of holes differs for the core and cavity sides, but it can range from 30 for a simple mold insert to 100 for a more complex design.

Mr. De Grandmont explains that by using a three-axis machine, operators would have to perform separate setups for each face of an insert block and also for each hole that wasn’t perpendicular to those faces. This could result in 10 to 25 different setups. Each setup means that the block needs to be unclamped, lifted with a crane, rotated and then re-clamped, aligned and zeroed on the machine before starting the next drilling or milling operation. Five-axis machining would enable the shop to complete all these machining operations in just two setups.

The company’s first step was to determine what type of five-axis machine would be most appropriate, because they are available in a number of configurations. Machines with trunnions were considered but eventually ruled out because trunnions limit the size of workpiece that a machine could otherwise accommodate. Most thin-walled container mold inserts aren’t terribly big. However, Moulexpert also serves customers producing precision die cast parts as well as plastic parts for automobiles, snow mobiles, watercraft and shovels whose molds might be too big or heavy for most trunnions. The same is true for the support plates for multi-cavity, thin-walled mold inserts. In addition, a trunnion’s inherent U-shaped body can prevent cutting tool access to some workpiece features, potentially requiring additional setups.

Moulexpert also wanted the machine to have a good deal of spindle power and torque to perform both drilling and rough-milling operations. Ultimately, the company chose an HPM 1350U machine from GF AgieCharmilles, which has a moving-column design. Its 360-degree C-axis rotation is provided by a 43.3-inch-diameter table having 3,527-pound load capacity. The spindle head provides A-axis rotation ranging from +16 to -120 degrees. Plus, the machine features a 15,000-rpm, HSK-A63 spindle with 51 horsepower and 142 foot-pounds of torque.

Mr. Nadeau says this universal machine provides the right combination of features for the range of work that runs across it. The table offers sufficient size without obstructions, and the spindle is versatile enough to perform drilling and tapping, as well as roughing and semi-finishing operations. During roughing operations, the A and C axes are hydraulically locked into position to provide rigidity for heavy cuts and long tool life.

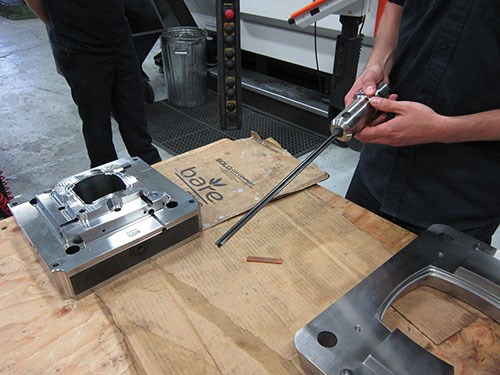

Unlike Moulexpert’s three-axis machines, the HPM 1350U has high-pressure, through-spindle coolant delivery, enabling the company to take advantage of more advanced cutting tools that are currently available. This is especially helpful for drilling operations with long carbide tools, such as the one shown above, because it facilitates chip evacuation to minimize the number of pecking retracts. Early on, the company received a good bit of advice from its cutting tool distributor, Baron Cutting Tools. Baron carries a number of tool lines and has worked closely with Moulexpert over the years, so it has a good understanding of the mold manufacturer’s tooling needs and, in this case, what tools should be considered to get the most out of the new five-axis machine. In fact, Baron is located in the same facility as Moulexpert, which greatly streamlines communication and interaction between the two organizations.

Software Choices

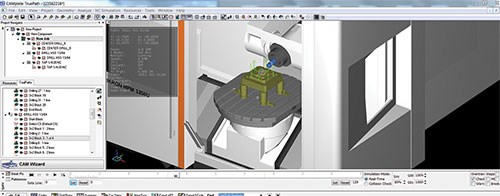

Even before settling on the type of five-axis machine to purchase, Moulexpert realized that simulation software would be an important part of its five-axis process, given the more complex choreography of tool and table movements. During discussions with GF AgieCharmilles, the mold manufacturer learned about TruePath software from Camplete Solutions, which the machine tool builder offers this as an option for its Heidenhain-based five-axis machines. TruePath is a machine-specific software platform that performs postprocessing, simulation and toolpath optimization.

Jeff Fritsch, Camplete’s vice president of sales, says his company has close relationships with select machine tool builders that provide 3D models of every standard and optional machine component. Mr. Fritsch says Camplete is the only software company with access to such machine-specific 3D models. This enables TruePath users to perform very accurate and detailed simulation in real time to detect and avoid collisions, view material removal, see the difference between the programmed five-axis tool path and the actual path the tool will follow, identify over-travel cutter positions and so on.

TruePath also generates postprocessors with support for all major CAM systems. As Mr. Fritsch points out, the postprocessor is the direct link between a shop’s CAM system and machine. However, many postprocessors for five-axis machines don’t account for the complex, non-linear motion unique to each type of machine. This can lead to unpredictable tool motion and variations in cutting conditions that can result in poor surface finishes, gouging and increased tool wear. TruePath generates error-free code tailored to the machine, he notes.

Mr. Nadeau says he purchased the optional TruePath software package because he appreciated this close integration of simulation, postprocessing and machine. It seemed like a plug-and-play solution.

In practice, a CAM programmer first develops a part program using PowerMill from Delcam. Once a program is completed, TruePath opens the PowerMill-generated .XML program file that contains all the data needed to properly run a simulation. This includes toolpath files, the tooling database, part models, the location of all data in reference to the machine coordinate system, etc. The programmer can then perform a simulation to verify the program before postprocessing.

Operators can also access TruePath at a computer near the machine to view the simulation and note the order of operations. One important advantage that the software offers is the ability to change that order of operations to suit production needs. Although the CAM programmer generates a sound, collision-free program, an operator who might be tending multiple machines could recognize that re-ordering the operations would result in higher spindle utilization. For example, it might make sense to skip some shorter operations on the five-axis machine that would require operator intervention and move ahead to a longer running operation. This would free the operator to tend to other machines that require immediate attention, rather than letting those machines sit idle. Running another simulation would ensure that the suggested change to the sequence of operations on the five-axis machine would not result in a collision. The key is that these changes automatically update the tool path and the G-code without having to re-post the program.

Beyond 3+2 Machining?

Mr. Nadeau envisions moving to full-five-axis contouring at some point, but the application would have to be right. For now though, Moulexpert is realizing all the benefits it envisioned when it first considered 3 + 2 machining.

And he’s still impressed with how smoothly the transition to five-axis machining was for the company. So, too, are the employees who voiced their initial concerns early on.

Related Content

Which Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

Read MoreHigh RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreFive-Axis Machines Speed NASCAR Engine Production

Moving from an aging set of five-axis mills to more advanced machines enabled Hendrick Motorsports to dramatically improve its engine production.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More