Not many manufacturing companies can say that one of the founders is a well-known movie star. CINC Industries of Carson City, Nevada, can. Kevin Costner, of Hollywood fame, helped get this company started in 1983. However, the company would rather talk about the vital role its products share in responses to critical situations such as environmental disasters. The recent oil spill in the Gulf of Mexico is a prime example. It’s a story that illustrates the key part the company’s machining capability plays in manufacturing some of the most efficient, most powerful centrifuges ever built.

The machine tools involved are primarily large lathes and turn-mills from Doosan Infracore (West Caldwell, New Jersey). In addition to other tight-tolerance workpieces, they are used to produce the rotors that represent the heart of a centrifuge. Precision machining ensures that rotors in the company’s largest models can spin as fast as 2,500 rpm with as much as 55 gallons of liquid inside the separation chamber. Because precise machining results in components that can be balanced to within a few grams for virtually vibration free rotation, the centrifuges operate efficiently and reliably even if the fluid inside changes composition widely. This versatility makes them ideal for environmental cleanup applications such as separating crude oil from seawater. The importance of this capability was proven in the Gulf of Mexico, where the ratio of oil and water varied greatly depending on conditions at the surface of the seawater.

However, the company’s centrifuges are also used in many other industries that require effective and economical liquid separation equipment.

The machine tools at CINC Industries have to be accurate and efficient to produce components in a range of sizes and a variety of workpiece materials. For example, the company requires its lathes to perform both rough and fine turning. According to Bret Sheldon, the current owner and president, the lathes that support milling operations are particularly valuable. Combining turning and milling eliminates setups and enhances part accuracy—important concerns when large, heavy workpieces are involved.

Combining and streamlining processes also help the company balance the production of its centrifuges with contract machining jobs, another part of its business.

Technology in the Spotlight

Actor, producer and technology advocate Kevin Costner is indeed one of the founders of CINC Industries. He and his brother Dan formed the company 27 years ago to manufacture a new kind of centrifuge based on technology developed by the U.S. Department of Energy for its nuclear programs. At the time, another oil spill disaster was in the news—the wreck of the Exxon Valdez tanker in Prince Williams Sound, Alaska, one of the Costners’ favorite fishing spots. Removing oil from the Sound’s once pristine waters became an urgent concern for them. They were eager to apply this new method of mechanically separating oil from seawater to help save the Sound. Dan was the engineer and hands-on shop manager at the new company, while Kevin (who has a degree in finance) was the financial backer and business promoter.

Originally, the company was located in

California. The success of the centrifuges in Alaska established the company as a viable business, and their innovative design was subsequently adapted for use by pharmaceutical companies, biodiesel fuel refineries, energy-related laboratories and other industries. Nevertheless, the Costners never lost interest in the technology as a potential boon in disasters such as an oil spill.

In 1995, the company relocated to Carson City, Nevada. Around this time, Mr. Sheldon joined the firm as manager of manufacturing operations. His background was in manufacturing and included a stint with Thiokol when that firm was building components for the space shuttle program. He eventually bought CINC Industries in 1997, but the Costners remained involved as technology advisors and supporters.

This involvement led Kevin Costner to take his case for the potential of this centrifugal separation technology to the U.S. Congress in May 2010 as the oil spill in the Gulf of Mexico was unfolding with catastrophic consequences. His testimony attracted much attention, ultimately leading to a surge in orders for CINC Industries’ largest centrifuge. These were successfully deployed in the Gulf cleanup effort.

Fortunately, the leaking well was capped in August, 2010, thus limiting the environmental damage caused by this accident. However, heightened concern about preventing and responding to oil spills at offshore drilling operations around the world has resulted in new orders for equipment from CINC Industries. In fact, the company has ordered additional machine tools to increase its machining capacity.

Setting the Stage

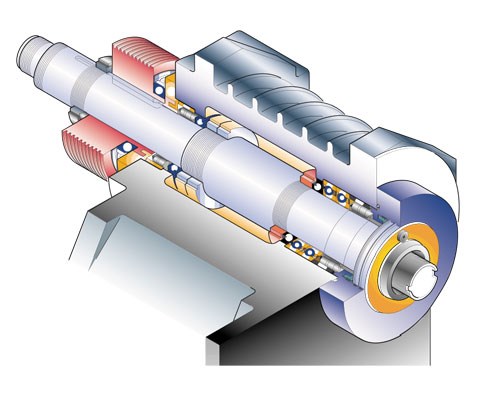

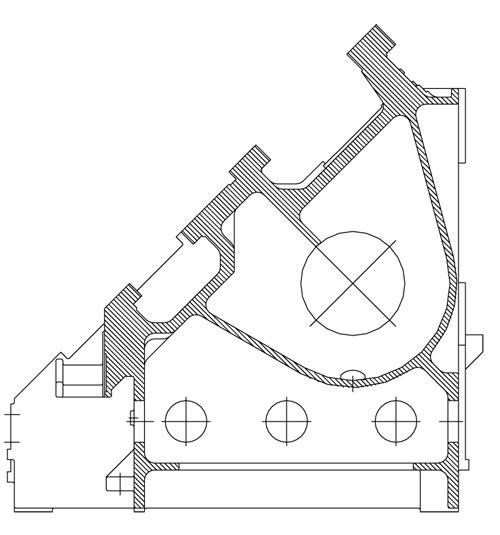

CINC Industries operates in a 61,000-square foot facility in a business park on the outskirts of Carson City, which is in the northwest corner of Nevada. It employs about 30 people in its manufacturing facilities. Producing centrifuges, the company’s flagship product line, involves a combination of fabricating expertise (especially welding) and precision machining capability. This combination is best exemplified in the production of rotors, the part of the centrifuge that rotates at high speed.

This rotation spins the liquid contained within the separation chamber. The resulting centrifugal force causes the lighter-by-volume oil to retreat to the inner portion of the chamber where it can be siphoned off, leaving only clean water behind. The unusual design of the rotor and chamber in CINC Industries’ centrifuges enables them to remove more than 99 percent of the oil from incoming contaminated water. Water departing the centrifuges is clean enough to return directly to the ocean, while the oil can be collected for eventual refining.

Most of the rotors are manufactured from a variety of castings that are welded together, then machined. A typical rotor requires about 15 separate welding and machining operations. Turning is the most important machining operation because it is ideal for creating geometry that must be uniformly symmetrical around a centerline. How well these parts can be turned on CINC’s machine tools directly determines how well they perform in the centrifuge.

Turning’s Leading Role

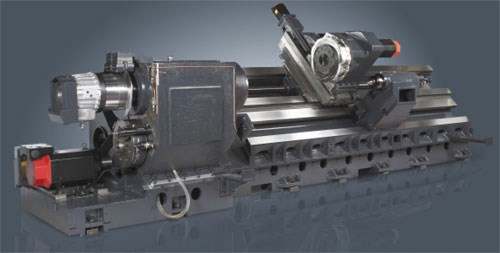

CINC Industries relies on two CNC turning centers for its large rotor turning capability: a Doosan Puma 400 LMB and a Puma 700.

Rotors for the largest centrifuge model are produced on the Puma 400 LMB. This 50-hp machine can turn parts as large as 22 inches in diameter and 80 inches between centers. According to Mr. Sheldon, the machine’s milling capability enables it to combine operations in one setup. For example, the long stroke of the C axis is especially useful for reaching features that would otherwise require complex setup on a milling machine. More importantly, eliminating additional setups results in a more accurately finished rotor.

Accuracy is critical because it affects the rotor’s balance, which determines its ability to rotate at high speed with low vibration. High rotational speed is necessary to separate large volumes of mixed liquids efficiently. At the same time, low vibration prevents bearings in the centrifuge from wearing excessively and increasing operation and maintenance costs.

Many of these rotors are large and heavy. To put this into perspective, Mr. Sheldon notes that the stainless steel rotor for the V-20 model, which can handle 200 gallons a minute, features an approximately 800-pound rotor measuring 20 inches in diameter. The liquid contained within the separation chamber might weigh as much as 400 pounds. By balancing the rotor to within 3 grams or less, the centrifuge can operate virtually vibration free at 2,500 rpm.

Although the Puma 400 LMB enables the shop to consolidate a number of turning and milling operations, the stainless steel rotors must be removed for heat treating before they are returned to this machine for finish turning. “This machine has the torque and rigidity to handle the rough turning operations as well as the precision for finish turning,” Mr. Sheldon says.

In addition to stainless steel rotors, CINC also produces Hastelloy models for pharmaceutical industry applications. Although these rotors are not the largest the company produces, the tough workpiece material requires a machine with higher horsepower and torque. Here is where the Puma 700 model fits in well. This machine has a 60-hp spindle motor and can accommodate workpieces as long as 65 inches with diameters ranging to 35.5 inches. This machine is capable of the heavy cuts required for machining Hastelloy, which tends to become work-hardened when subjected to light cuts.

According to Mr. Sheldon, the Doosan machines have proven to be reliable workhorses that hold tight tolerances. He attributes this to the size and weight of their Meehanite cast iron beds. The beds feature torque tube construction, which means that they are built around a cast iron cylinder. The cylindrical shape is naturally resistant to flexing, thus enhancing the machine’s overall rigidity. Boxway construction of the axis ways also keeps the machine rigid, especially under the load of cutting at full power. These features enable the shop to hold precision despite the large size of the parts. “We routinely produce rotor bearing surfaces on these machines to ±0.0002 or 0.0003 inch, depending on the size of the rotor,” Mr. Sheldon says.

Not a One Act Play

The shop’s newest machine is a Doosan Puma VT1100, a vertical turning lathe. This machine accommodates workpieces ranging to 45 inches in diameter and 40 inches tall. It features a spindle motor that is rated at 60 hp (continuous) and 75 hp (30 minute heavy duty cycle). Besides giving the shop another resource for turning large parts, it will also support production of a V-40 model centrifuge that CINC Industries is developing. This model will process even larger volumes of liquid and provide even higher separation rates than the largest current model. Rotors for the V-40 will measure 40 inches in diameter.

Because CINC Industries does contract machining in addition to producing its line of centrifuges, having a range of large turning centers and turn-mills enables the company to attract jobs from customers in the nuclear power, wind turbine and other industries, Mr. Sheldon says. This strategy of diversification has served the company well during the recent recession.

Nevertheless, the company intends to keep its focus on its line of centrifuges. Although the Gulf oil spill is no longer in the headlines, cleanup efforts are still underway. Moreover, companies moving toward sustainable manufacturing and green technology are increasingly interested in zero-discharge operations. This trend, Mr. Sheldon believes, will create new applications for high-efficiency separation of liquids for recycling.