Loading the player ...

Roughing the same pocket, OptiRough reduced total machining time by nearly two-thirds compared to traditional techniques.

When programming roughing routines to mill a contoured pocket, the usual concept is to employ a big cutter, use its full diameter to sweep out the material at a Z-level depth that allows quick removal of the material, then drop to the next Z level. This proceeds until the cutter is too big to accommodate further tool paths within the pocket’s geometry. The remaining material must then be removed by smaller cutters as milling operations bring the workpiece close to its net shape.

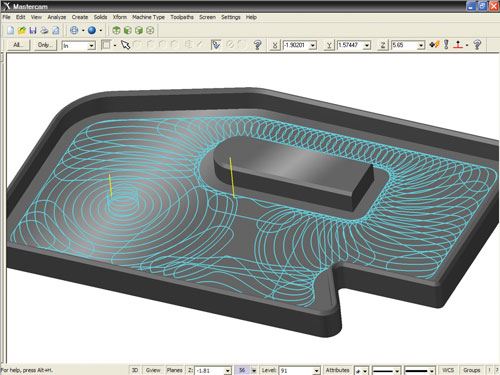

Mastercam from CNC Software Inc. (Tolland, Connecticut) has added a new feature in the X5 release of this software that follows a different, somewhat counterintuitive approach to roughing. The basic idea is to start with a small tool that cuts very efficiently at an initial depth using the full length of its flute. This new roughing technique is called OptiRough.

This roughing technique is based on the Dynamic Milling capability introduced in an earlier version of this software. Dynamic Milling is a pocketing/contouring technique that constantly monitors tool engagement and adjusts the tool path to maintain a consistent load. Resulting tool paths do not have the “plowed cornfield” look that results when the tool centerline follows the contours of the pocket. That’s because Dynamic Milling avoids the corner turns that tend to bury a cutter as it changes directions. Instead, the cutter moves in arcs and circles at a speed and feed that optimize chip formation and minimize tool wear for efficient, economical material removal, the company says.

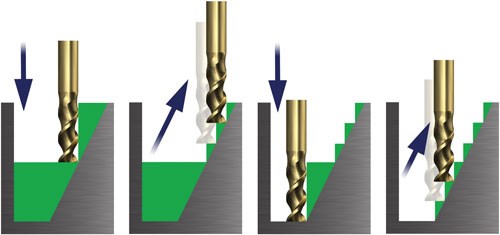

OptiRough applies this milling strategy to roughing. The following example is given to compare typical roughing techniques to the new one, and to show the benefit of using a small cutter to full depth. The task is to rough out a pocket with a boss in the center. The material to be roughed out is 1.2 inches deep. The typical approach might take a 0.2-inch deep cut using as much of the cutter diameter as possible, leaving a level floor at this depth. The next cut would proceed at another 0.2-inch depth, followed by successive cuts at the same depth until the desired metal removal was achieved.

The new technique starts with a cut that is 0.6 inch deep, but follows the Dynamic Milling pattern. (This example assumes that 0.6 inch represents the full flute length of the cutter.) Tool paths are such that only a small but consistent percentage of the tool diameter is engaged with the material. Limiting tool engagement allows the cutter to travel at high speed, thus removing a large volume of material. After cutting aggressively at that initial level, the cutter then takes lighter, successive up-cuts at 0.2 inch steps. The roughing program then repeats at a second 0.6 inch depth, followed by more up-cuts at 0.2 inch. The picture on this page illustrates this new pattern.

Tests conducted by the developer show that this OptiRough technique leaves the same specified roughness as the conventional approach, but requires far less machining time and lighter, more even wear on the cutting edges. Using the small cutter has other benefits. For example, a small carbide tool is likely to be a less expensive than a larger one because it contains a smaller amount of the costly carbide material. It is also likely that a tool already stocked in existing inventory will be usable for this kind of roughing. Furthermore, no time is lost switching to cutters of different sizes to complete the roughing routine.

Mastercam X5 includes a number of other new features, including additional Dynamic Milling techniques, a plunge turn toolpath strategy, enhanced simulation for multi-axis machining and a suite of new surface and solid analysis tools for design.

.jpg;maxWidth=300;quality=90)