Share

Hwacheon Machinery America, Inc.

Featured Content

View More

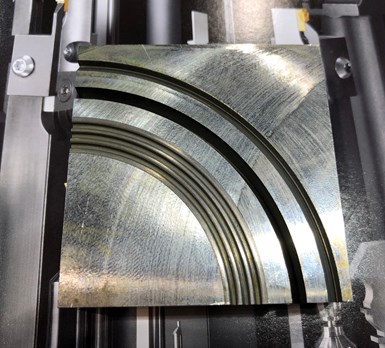

Until recently, shops had two options to machine circular grooves in the face of a part. One is to spin a part in a turning center and feed in a static face-grooving tool. The other is to use a machine tool to circle-interpolate using an end mill. Shops typically go with the latter option when the part cannot be chucked in a turning center, has a geometry that includes bosses or features impeding tool access, or would create an out-of-balance condition when spun. However, tool breakage and long cycle times can be an issue, especially when using small-diameter end mills. Plus, those tools create only symmetrical groove profiles.

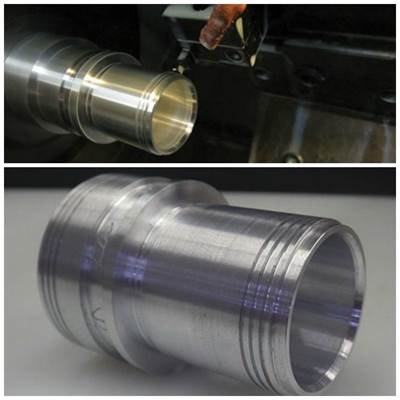

This tool enables a range of groove diameters — with a symmetrical profile or not — to be created.

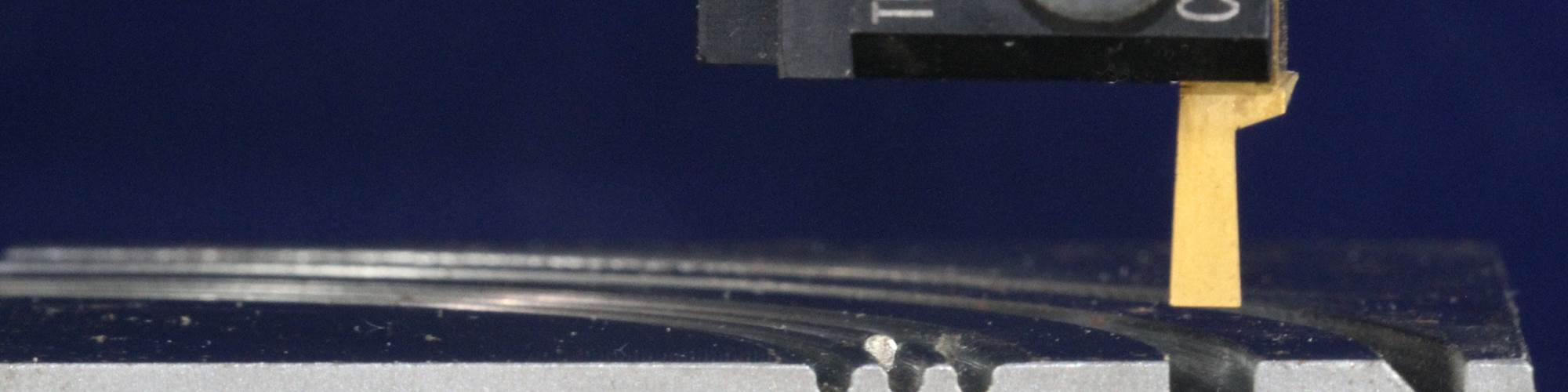

Recently, Thinbit/Kaiser Tool Co. has developed a trepanning-type tool based on the static, lathe, face-grooving inserts it has offered for many years to enable single-point cutting of grooves on a machining center. Called Mill A Groove, this line of tools installs in a user’s boring head to enable a range of groove diameters — with a symmetrical profile or not — to be created.

Custom insert profiles can be created based on application requirements.

“We’ve noticed an increasing number of applications in which end mills are used on machining centers to create face grooves primarily for seals or where parts mate together in an assembly,” says company COO Ken King. “With Mill a Groove, we’re using our lathe face-grooving inserts, which range in widths from 0.004 to 0.150 inch, in a newly designed toolholder to enable trepanning operations on a milling machine.” (See video of this tool in operation.)

Mr. King says compared to end milling, this tool offers advantages such as better groove concentricity and surface finish. It can also eliminate the need to take a milled part to a lathe for a secondary face-grooving operation. In addition, tests have shown that the tool can produce grooves as much as 90% faster than machining with an end mill. The Mill A Groove produced a 0.125-inch-wide face groove in steel in 18 seconds versus three minutes with an end mill. Cut data for the Mill A Groove is determined by simply converting the speeds and feeds used in a lathe face-grooving operation to a single-point milling operation.

Shanks are available in seven sizes to accommodate a range of boring head models.

The Mill A Groove can also be used to perform face milling as a single-point, fly-cutting operation. This can be advantageous for applications in which minimal machining witness marks are desirable. For example, using a 1-inch end mill to face a surface wider than that will leave behind multiple 1-inch rows of witness marks. Setting up a Mill A Groove tool in a boring head with a diameter bigger than the part width and performing a fly-milling operation leaves a more uniform surface finish.

Mill A Groove shanks are available in seven sizes — 0.5, 0.625, 0.75 and 1 inch and 16, 20 and 25 mm — to accommodate a range of boring head models. Custom insert profiles can be created based on application requirements.

Related Content

GWS Tool Group End Mill Provides Dynamic Milling

Eastec 2023: The Hurrimill AT4 all-terrain end mill features radial-end gashing, which enables drilling, steep ramping and aggressive helical entry.

Read MoreThe Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

Read MoreKennametal's Expanded Tooling Portfolio Improves Performance

The company has launch eight new products that expand on and support existing platforms across multiple applications.

Read MoreTungaloy Expands Line of Barrel-Shaped End Mills

The new SolidMeister barrel end mills are efficient tools for complex 3D-surfacing operations used in mold making, orthopedic implants and the machining of other freeform surfaces.

Read MoreRead Next

Economies of Usable Cutting Tool Edges

Recent introductions from a major cutting tool maker illustrate the engineering and application of tools designed to deliver an increased number of useful edges.

Read MoreThe Right Tools for Micro Grooves

Mack Tool and Engineering used modified inserts to create micro-grooves, but they were prone to breaking. After switching to Thinbit Groove ‘N Turn tools from Kaiser Tool, the company experienced increased tool life.

Read MoreCoolant’s Impact on Face Milling Aluminum

Testing shows that understanding the interplay among cutting speed, tool wear and cutting power can lead to more informed evaluation of metalworking fluids and more predictable machining.

Read More

.jpg;maxWidth=300;quality=90)