A Manufacturing Road Map

This hydraulic system producer describes why and how it implemented an ERP solution.

Share

At the Milford, Michigan, manufacturing facility of A.B. Heller, it used to be that every department—from quality to accounting to manufacturing—set its own schedules, monitored its own overtime and conducted activities differently from shift to shift. “We basically had islands of information and no universal management system in place,” says Ashish Patel, chief operating officer. Most departments had their own spreadsheets or systems for tracking data. Frequently this data either was outdated or conflicted with other areas of the shop. “It was starting to have an adverse effect on our business in terms of production and efficiency,” he says.

Recognizing this problem, Mr. Patel and CEO Robert Dalton began the cumbersome task of gathering information to determine how A.B. Heller could improve shop performance and production. They wanted an integrated management system that was cost-effective, easy to operate and highly scalable. One that would bridge the communication gap between departments and help A.B. Heller become a leaner, more effective manufacturing organization. Many shops want to achieve this integration; A.B. Heller actually did it. The company’s successful implementation of enterprise resource planning (ERP) software should be of interest to any business hoping to gain a holistic view of its entire operation.

First, some company history.

A.B. Heller is a full-function CNC machining operation handling parts for high-pressure hydraulic systems (diesel and natural gas fuel systems). In the 1980s, it produced 4 million parts per year for a single component: a fuel stop for a hydraulically activated, electronically controlled unit injector (HEUI). Today, it produces fewer than 1 million parts per year of several different components, including orifice plates, valve plates, stops and neck studs.

The TS:16949- and ISO 140001-certified company has more than 125 machines for processes including turning, grinding, milling, lapping, and measurement and inspection relevant to these operations. In 2003, it relocated to an 80,000-square-foot facility in Milford, and it ramped up production just in time for business to slow down significantly in 2007-2008. While obviously not good from a production standpoint, this slowdown gave management an opportunity to examine the company’s core policies and make necessary improvements.

Why Invest in ERP?

Through his research, Mr. Patel realized the way data was being collected and received in every department at A.B. Heller was the organization’s greatest weakness. These various systems couldn’t communicate with each other. Discussions with the management team kept coming back to a need for an integrated ERP system that could provide two key benefits:

1. Utilize the same data and network in every department.

2. Move products and orders at a more productive rate.

“Our business metrics spelled it out for us. We were lacking in several key performance areas, and we needed to become more efficient, top to bottom,” Mr. Patel says.

Mr. Patel wanted a software system that was suited specifically to manufacturing. One that could collect time sheets and schedule jobs as well as purchase raw materials and streamline shipping and receiving.

From his own past experience, he knows that it’s important not to have unrealistic expectations of ERP. “The software is not a magic wand,” he says. “It’s not going to change your bottom line overnight, but it can assist you in storing, managing and collecting data seamlessly from department to department.”

He also believes that, for a facility of A.B. Heller’s size and scope to invest in an ERP solution, it’s valuable to have a few people on staff who understand how the software ultimately works. Mr. Patel has a background in ERP and information technology, as well as a master’s degree in project management and organizational development. A.B. Heller’s management team knew about potential budget, training and hardware issues that might come up before, during and after ERP implementation. This would help alleviate issues that would occur down the road. It would also help in the rather detailed process of choosing an ERP software to match the company’s manufacturing operation.

Selecting an ERP Vendor

The executive team at A.B. Heller looked at both large and small ERP providers when it began shopping for software, not wanting to rule out any potential products. It looked at large integrated systems offering a wide range of capabilities, as well as smaller, more focused products built specifically with manufacturing customers in mind.

“The large vendors obviously had a great product,” Mr. Patel says. “The technology was top-of-the-line, it looked fantastic, and it could do more than most of the competition, but the learning curve and the cost seemed extreme.”

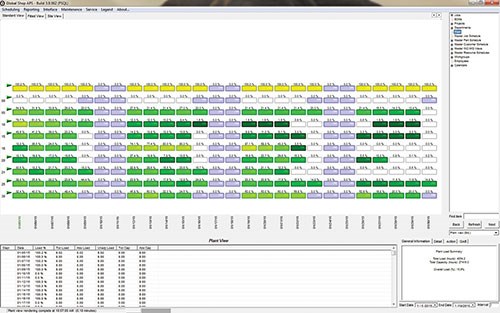

A tool manufacturer in Saginaw, Michigan, that worked with A.B. Heller was using an ERP program from Global Shop Solutions, which focuses specifically on solutions for manufacturing. Mr. Patel and part of the executive team took a tour of the Saginaw facility, spent time with the employees and received a firsthand account of the software’s performance. Seeing the data system in real time on a shop floor proved invaluable.

“The most important piece of advice I can give about ERP software is this: See the system live in a manufacturing environment,” he says. “We knew exactly what we were getting into based on this shop visit. We also saw a lot of things with the demo of this particular software that we could easily transition into our own business.” This included a routing system that mirrored the existing one at A.B. Heller, data reports that could be customized to personal preferences and a quality control system that could work hand-in-hand with lean manufacturing principles.

ERP Implementation

A.B. Heller wanted to have the ERP system up and running in 90 days. Data conversion was one of the first priorities. This included importing old Excel files, updating customer information and getting rid of outdated records. Basically, this meant taking all the existing data from A.B. Heller and finding a way to make it work in an ERP system, a task that, according to Mr. Patel, took many long nights and lots of prep work.

The next priority was training. With a staff of 130, management had to designate “power users” from each department who would be assigned to train other staff on the ERP system. A “play” company identical to A.B. Heller was set up strictly for experimentation. The executive team added all A.B. Heller part numbers, routers, work centers, vendors, etc., as data for the play company to assist in the training process. “We had the ability to train users and verify our settings without polluting the new system,” Mr. Patel says. “Employees were trained without having the fear of doing something wrong or deleting information. We could learn (and teach) from our mistakes. This was very helpful.”

Global Shop Solutions periodically sent an implementation manager to check on A.B. Heller’s progress, answer any questions and provide further feedback. The implementation manager’s role was to recommend certain aspects of the ERP system that would be beneficial everywhere from the accounting department to the manufacturing floor. It was the job of Mr. Patel and the management team to determine what software features worked and what didn’t.

“Bob and I were done with the pilot program after four or five visits from the implementation manager. It was more important to see how these changes looked on the actual shop floor than in the training model,” Mr. Patel says. They wanted to know what software tools would work best for tracking work-in-progress (WIP) orders, for example, or how older purchase orders would be received in the new system. The software features needed in the accounting department had to be customized.

Unfortunately, the play company couldn’t give the management team a clear idea of how such features would work at A.B. Heller, so the team began making changes in the real system. Communication was very important during this phase of the operation. “If I made a change, the rest of the management team would know about it,” Mr. Patel says. “This would have been more challenging in a larger organization, but I wanted to see what these changes would look like before we went live.”

The work and the research paid off. The live system was in place in 60 days instead of the planned 90. By October 2008, A.B. Heller had successfully implemented ERP software.

Identifying the Roadblocks

Despite the smooth implementation, Mr. Patel would have changed some things if he had to do it all over again. Training the staff, for example. While the company designated power users in key functional areas by department, the rest of the staff was far from comfortable using the new system when A.B. Heller went live. Many of the employees had never worked in a system like this before. “The play company was extremely helpful, but it didn’t have the same impact someone would get from actually using the software to do their job,” he says. “I think we could have handled this better if the training involved more real-world scenarios on the shop floor. Our employees needed to see something they could actually connect with.”

Long-term investment into ERP is another area that has proved somewhat challenging for A.B. Heller. It’s also one of the more important aspects of selection and implementation of a system, according to Mr. Patel. “The vendor provided a great deal of specifications on what we could do and what we could achieve with the software, but we were responsible for planning for the future,” he says. “This is where many mistakes can be made.”

For example, Mr. Patel recommends that a company consider what its ERP hardware and storage needs might be five years from implementation. Is the RAM expandable? Is it a storage solution that can change if needed? Will the company be able to budget to keep the software up-to-date in areas like speed and security? Mr. Patel stresses the importance of future financial planning for ERP. “Be prepared to spend more money to keep the ERP system optimized,” he adds.

Is it Worth the Investment?

Six years since implementation, the ERP system has made day-to-day activities more manageable for A.B. Heller. Mr. Patel says there is a sense of unity now among the departments; accounting, shipping, manufacturing and quality control have better tools at their disposal. The software also has been pivotal in controlling and tracking operational costs.

In addition, the software has made it easier for staff to access part information. This was one of the biggest focuses when Mr. Patel was originally evaluating ERP systems. A parts supply/demand option allows users to get the history and geography of a part—not just its sales history, but how it is made and what material is used. A reporting option enables the user to dig deeper into a specific transaction and pull up any relevant information, all at the push of a button.

With the ERP system in place, the shop floor at A.B. Heller has transformed into a state-of-the-art manufacturing facility that utilizes both the software and lean manufacturing principles through several work cells. Data accountability and intercommunication has increased productivity within each department. The “islands of information” have disappeared, according to Mr. Patel.

Employees now have a clear, detailed set of guidelines to help them maximize the work they do on a daily basis. Additionally, the ERP system has helped A.B. Heller provide faster response time and improved customer service, he adds.

Mr. Patel compares the whole ERP project to putting a large factory-floor jigsaw puzzle together, analyzing where and when to put each piece along the way. “If all the pieces of the puzzle come together into one picture,” he says, “then that unity is what justifies the decision to implement ERP.”

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreCan AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More