A Breakthrough in Power Skiving

Advances in machine design, cutting tools and process simulation software have finally converged, making it possible for Gleason to offer a practical and highly productive power skiving solution. Here’s how the new process can revolutionize the way internal gears are produced.

Share

By Dr. Edgar Weppelmann, Manager of Application Engineering, Gleason Pfauter Ludwigsburg and Johannes Brogni, Technical Director, Gleason Pfauter Studen

When Wilhelm von Gleason CorpPittler filed his skiving patent in 1910, no one could have imagined that such a promising new process for producing internal gears would take about 100 years to finally realize its full potential. It’s true that, along the way, some in our industry have made brief forays into skiving. For example, Pfauter, which was aquired by Gleason Corp. (Rochester, N.Y.) in 1997, introduced skiving machines in 1968, 1985 and, most successfully, 1999, with its PF 200, a machine that used skiving as a hard finishing process. Yet none of these solutions achieved the full promise that many in our industry believed skiving held, particularly in comparison to shaping. On paper, at least, it’s long been recognized that skiving would be a much more productive process than shaping for cutting many (but not all) internal gears. Shaping generates the gear teeth with an oscillating stroke movement—a downstroke that performs the cut followed by a nonproductive return stroke. Consequently, a great portion of the shaping cycle time consists of noncontact time and acceleration/deceleration of the stroke movements.

Power skiving, on the other hand, is a continuous cutting process that produces a gear in a much shorter time because it almost entirely avoids noncontact situations as well as frequent acceleration movements. This continuous cutting process makes power skiving about four times faster than shaping.

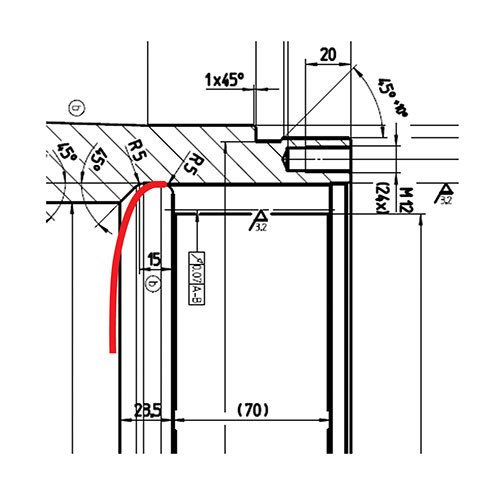

Similar to hobbing, the skiving cutter can produce the gear in one or more cuts. Each cut performs a radial in feed, or depth of cut, followed by an axial advance movement on every tooth over the entire gear face. The rotating skiving cutter intersects the rotating gear at an angle (the cross-axis angle). The cutting speed, which is the speed of the cutter tooth tip along the gear tooth gap, is a result of both the circumferential speed and the cross-axis angle of the cutter.

While this concept seems practical, an economical and effective skiving solution proved to be elusive for more than 100 years. Machines and cutting spindles simply weren’t robust and rigid enough to minimize vibrations caused by the high spindle rpms and significant cutting forces generated by the skiving process; cutting conditions were such that tool life was prohibitively low; tool substrate and coating materials were not yet at today’s advanced high levels; and, most significantly, no method existed for end users to adequately simulate and optimize the skiving process in advance. Today, Gleason Power Skiving completely solves all of these century-old challenges, and more.

From Concept to Reality

The vibrations caused by the dynamic nature of the skiving process and the need to machine at high rpms made it very difficult to perform the process on older mechanical machines.

The mechanically connected axes and spindles in those machines act like an elastic spring system, thus exacerbating the vibration challenge. Fortunately, the company’s latest generation of gear manufacturing machines offers a particularly stiff and rigid starting platform. For example, on the smaller end of the part-size spectrum, Gleason now offers the 100PS, a horizontal-spindle machine built on the P 90 machine platform currently used in hobbing and grinding applications worldwide. Working in conjunction with new direct-drive spindles equipped with oversized bearings to increase rigidity, as well as a tailstock, the inherent rigidity of the 100PS makes it a highly versatile solution for power skiving smaller disc- and shaft-type parts. A gantry loader also is available to automate workpiece loading/unloading to minimize non-productive change-over time.

In a similar fashion, the larger 400PS and 600PS power skiving machines are built on Gleason’s vertical large hobbing machine platform, using the same massive frame and rigid guideways. Like the 100PS, these machines also are equipped with specially designed spindles, all with oversized diameters and larger, more-rigid bearings.

On these larger machines, Gleason decided not to offer a tailstock because it would have meant compromising the size and rigidity of the tool spindle. Now, the tool spindle has a large diameter that is ideal for power skiving, but too large to allow for a tailstock. Similarly, the table spindle’s use of particularly large and rigid bearings means that it can’t operate at the high rpms necessary for smaller pinions, but makes it a very well-suited machine for power skiving larger internal gears.

Power skiving produces “V”-shaped chips, which are extremely aggressive because they easily stick to any machine surface or corner and don’t slide well on sloped surfaces in the direction of the chip conveyor. Gleason’s power skiving machines operate wet to enhance chip evacuation and avoid chip accumulation as much as possible. On the large 400PS and 600PS machines, the vertical machine concept, together with a workholding concept that has been specially designed for improved chip evacuation, helps to move the chips down and away from the gear. In addition, the workholding is flushed with oil to keep it clean from the inside during the entire machining cycle, including loading/unloading.

Improving Tooling

Previous skiving attempts often proved impractical or failed altogether because of very poor tool life. This was the result of several different factors: Machining conditions were not ideal, there was no effective way to really understand cutting conditions for various process settings, and cutting tool substrates and coatings had not advanced to the levels they are today.

Now, engineers from the Gleason Cutting Tool Corp. in Rockford, Ill.—together with application engineering at Gleason Pfauter, Ludwigsburg, Germany—have developed a new generation of power skiving cutting tools that consider the detailed requirements of the power skiving process. During this tool development, the results from the detailed simulations of the entire process along with the results from numerous cutting trials were incorporated into the new cutter design.

This resulted in a successful design, generally similar to a shaping cutter, yet different in various important aspects. In many cases, the G50 PM HSS substrate is used which, in combination with Gleason’s AlCroNite Pro advanced coatings, delivers the high hardness and toughness characteristics needed for both productivity and extended tool life during power skiving. Machine setup, cutter handling and logistics remain as simple as in shaping.

When resharpening is needed, the end user sends it out to a local resharpening source that resharpens the face, strips, recoats and returns the cutter within a few days. The profile quality remains untouched.

Also note that operating in conjunction with new machines and the power skiving process, Gleason’s cutting tools are designed to provide higher quality and better surface finishes than shaping has traditionally delivered. The power skiving generating motion provides a “softer,” less-abrupt chip formation that is smoother and more consistent throughout an entire cut. Profile modifications as well as a tooth tip chamfer can be built into the cutter while lead modifications are realized by additional movements of the machine axes. The cutting cycles can be modified for aggressive roughing and fine finishing to maximize both productivity and quality. Profile, lead and tooth thickness can be corrected according to the results shown on the inspection charts. Ultimately, a quality of DIN 7 or better and surface finishes of Rz 4 μm (Ra 0.6 μm) are possible.

Simulation Software

Until recently, it was impossible to effectively establish the boundaries at which the skiving process exceeds its limits and won’t work well. Nor was it possible to truly optimize the process in advance due to the lack of appropriate software. Anticipating chip formation and collision points was difficult, if not impossible, to evaluate without the appropriate software.

Today however, Gleason offers comprehensive Power Skiving Technology Software that enables end users to easily simulate the entire cutting process and plan the most effective process strategy. The software can analyze the influence of different cutting tool geometries and process parameters on chip formation, gear quality, collision situation and cycle time. Now, the total cost per gear can be calculated considering the best-suited cutter size, the cost for a new cutter, and the cost for resharpening in combination with the expected cutter life. The software allows end users to decide if a given part can be safely and economically power skived or whether it would be better shaped. Ultimately, it makes the implementation and application of power skiving as simple and familiar as shaping.

Closing the Loop

Gleason Cage and G-age software helps optimize bevel gear production operations and connect Gleason gear inspection equipment to Gleason production machines to streamline part program corrections.

A similar software capability exists for users of Gleason Power Skiving machines, in conjunction with the company’s line of GMS gear metrology equipment. Measurements and corrective actions can be performed quickly and automatically, all monitored by the operator.

Geared for the Future

Still, many jobs remain for shaping that aren’t particularly well-suited for power skiving. And it generally is neither faster nor more economical than hobbing, which in some cases limits applications for external gears to gears that have interfering contours.

Yet, for many gear applications—ranging from small internal gears to internal gears as large as 600 mm in diameter as well as for a variety of external gear applications that cannot be hobbed—Gleason Power Skiving will finally deliver on the potential that Wilhelm von Pittler saw for his skiving patent more than 100 years ago.

Read Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More