5 Ways to Use Slow Business Periods as an Opportunity

Start looking at slow business periods as an opportunity to make your shop better and to prepare for the economic turnaround.

Share

The machining world is always going through an up and down business cycle. We are now hearing and seeing a downturn in the economy, and I have seen this same pattern in manufacturing many times over the last 40 years. Some downturns lasted longer than 2 years, though I suspect this one will not be that long. When this happens, I do not dwell on the downsides of the economic downturn, but rather, I think about the upside and the opportunities that it represents.

For many, a downturn means a lot of belt tightening and cutbacks. Although I agree that some of that is necessary, it is not the best way to deal with business slowdown. I want to review some of the opportunities that a small downturn represents. Here are five ways to use the slow business period as an opportunity:

- Prospecting. Many small shops find it difficult to prospect when the machine shop is busy. A slowdown gives these shops time to engage with new and existing customers to explore future opportunities. When customers are busy, they are less likely to entertain new suppliers. There just is not the time to have those conversations and onboarding a new vendor. Slow times change this, since everyone wants to keep busy. A slow period is an excellent time to really work hard on expanding your shop’s contacts and opportunities.

- Process refinement. In busy times, machine shops do not have the time to refine production or machining processes. This is understandable, since deadlines prevent us from taking the time to try to improve cycle or throughput time. When things are slow, this provides the opportunity to invest in optimizing your cycle and throughput time so when things turn around you can be much more productive. This means, when the economy turns around, you can take advantage of it by being more proactive.

- Job Training. One of the most overlooked opportunities in an economic slowdown is training. Most companies are more interested in laying off workers to reduce costs. Machine shops are no exception. I find this to be the most short-sighted way of running a business. Shops invest a lot of money and time to recruit qualified workers, and yet, when business slows down, they shed these skilled workers quickly. I do not think this is the right way of running a machine shop. Unless business is very bad, I truly believe that the best option when business is slow is to do more training. This can be in the form of cross training or enhanced skills training. This will help the machine shop prepare for the next upturn. The other issue is that if you are quick to lay off employees, then they will be reluctant to return when business picks up.

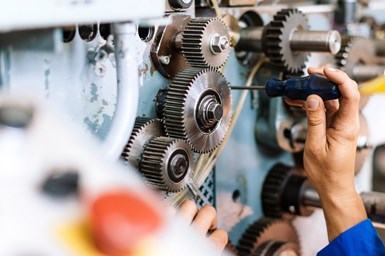

- Equipment Service. I cannot emphasize enough about equipment maintenance. When business is very busy, shops are very reluctant to do maintenance on equipment, and many only do maintenance during busy times because they have to. This usually means that a piece of equipment has broken down and it is mission critical. This type of decision making is not good, since it can lead to a failure to deliver to the customer on time and add unnecessary stress to the business. To mitigate customer disappointment and employee stress, double down on maintenance through the slow times so that equipment is less likely to have issues when your shop is busy.

- Future Planning. When shops are busy, they never seem to have the time to research and plan how to expand or optimize their services. Many machine shops do not have a vision on what they want the company to look like in the future. Equipment purchases are only contemplated when shops are extremely busy so shops can address bottlenecks or capacity issues. I believe that equipment purchases should be done when it is slow, which might be counterintuitive to how many shops operate. The reason I advocate for buying equipment when it is slow is that it relieves the stress of decision making. More rational decisions can be made in slow times and you can wait for delivery if needed. Shops need to make the big decisions without added pressure. Slow times are the best for this.

Many manufacturers look at slow times as losses, but it is important to start looking at slow times as an opportunity to make your shops better and to prepare for the turnaround. If you invest time and energy into the five points mentioned, your company will do well in the busy times even though it is slow today.

Read Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=300;quality=90)