Share

Autodesk, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View MoreConversations about the future of transportation tend to focus on electric vehicles (EVs), autonomous cars and electric air taxis — in other words, vehicles meant as alternatives to gas-powered cars that are largely intended for personal transportation. Additive manufacturing (AM) gets brought into these conversations for its ability to create lightweight geometries that support fuel efficiency and often assembly consolidation. But these very same benefits make metal AM an attractive production option to another sector that is facing “the race to zero emissions” in transportation too: the rail industry.

A train is complex mode of transportation with one locomotive potentially towing dozens of cars behind it. And unlike a personal automobile, the locomotive has to account for the terrain in front of it as well as behind; the front of the train might be climbing a hill while the back cars are still descending the previous one. Yet the rail industry is facing similar pressures to meet sustainability goals, reduce emissions and improve fuel economy, plus support new hybrid and fully electric locomotives. These are challenges that additive manufacturing can help meet.

Wabtec’s N91 space is dominated by its metal 3D printer, an SLM Solutions SLM 800 with a build volume of 850 × 250 × 500 mm.

I recently had a chance to visit Wabtec, a locomotive manufacturer with more than a century of history in this space, and see how they are applying metal 3D printing technology in support of more efficient rail transportation. The Pennsylvania-based company was the first tenant to move into Pittsburgh’s Neighborhood 91 ecosystem, a project that aims to bring all the pieces of the metal AM supply chain together on one campus. While Wabtec has additive manufacturing capacity elsewhere, its N91 facility is fully dedicated to production through laser powder bed fusion (LPBF; a process that uses one or multiple lasers to selectively melt powdered metal to build up a part).

As I learned, locomotives are complex machines that can have upwards of 200,000 unique parts. Today many of these components are made individually and welded, brazed or otherwise joined together; the total assembly process can take almost a month. Wabtec sees additive manufacturing as a way to help reduce that time by consolidating more of these pieces, as well as a means of reducing weight and improving the performance of the final vehicle. Lighter weight is not always a benefit — for freight trains, a heavier locomotive can be desirable — but for passenger trains, the main market that Wabtec’s N91 facility is serving, it is a boon to energy efficiency.

Below are several examples of parts now in production at this facility:

Engine Control Chassis

This chassis provides cooling to various engine control computer units for a dual-fuel locomotive (one that runs with both diesel and natural gas). Previously this chassis was produced by brazing various machined parts together; now, with Wabtec’s large-format metal 3D printer, it is possible to print each one as just one piece. This saves time in production and also reduces the cost of the component significantly, the company says.

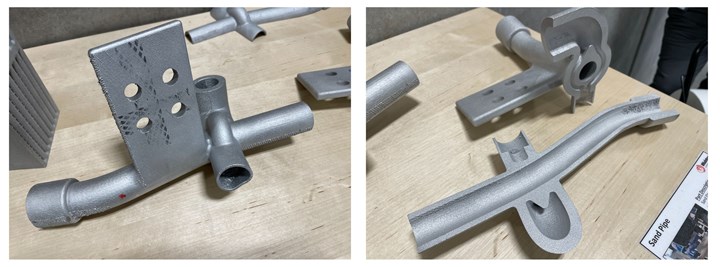

Sand Pipe

Because both train wheels and tracks are smooth steel, locomotives need assistance to gain traction. Pipes like this beneath the locomotive spray a blend of air and sand to create friction. In the past these parts would have been produced by bending and welding the pieces together in a time-consuming process, but 3D printing makes it easy to produce them in just one piece. Design changes (see the cutaway, right) have also been made to help reduce the weight of these components and improve the flow of media.

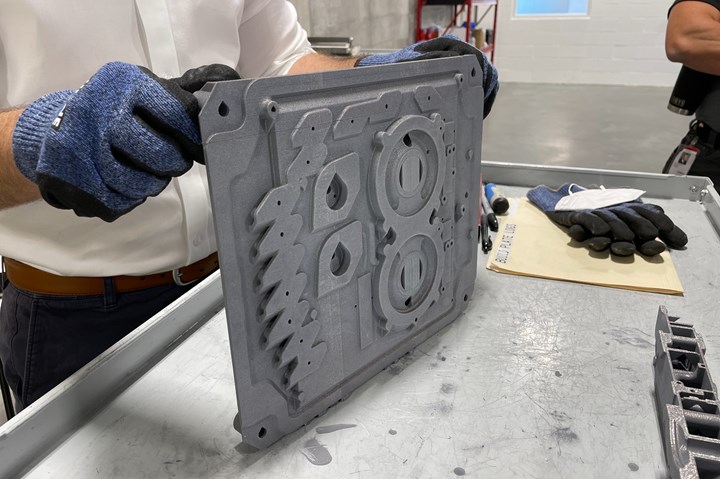

Brake Control Panel

This integrated brake control was previously assembled from 32 separate parts. Switching to 3D printing allowed Wabtec to produce the full panel in one piece and also reduced its weight from 7 to 2.3 kilograms. The company can now customize and change the design more easily because there is no tooling needed; redesign is possible by altering just the digital files associated with the part.

For more on how Wabtec is using metal additive manufacturing technology to improve the performance of its locomotives (as well as the role that machining plays in finishing these components), read the full story on AdditiveManufacturing.Media.

Related Content

6 Trends in Additive Manufacturing Technology

IMTS 2024 features a larger Additive Manufacturing Pavilion than ever before, with veteran suppliers alongside startups and newcomers at the front of the West Building. As you browse these exhibitors, as well as booths found elsewhere at the show, keep an eye out for these trends in AM.

Read MoreAdditive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreDigitalization and Done-In-One Reign Supreme at BIEMH 2024

European manufacturers may have a different balance of markets than their U.S. counterparts, but the practical challenges they must overcome are often similar — as are the solutions.

Read MoreThe Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D printed parts.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)