3D-Printed Titanium Bike Frame Manufactured for Empire Cycles

An additive manufacturing technology supplier collaborates with a British bicycle company to create what the two companies say is the world’s first 3D-printed metal bike frame.

Share

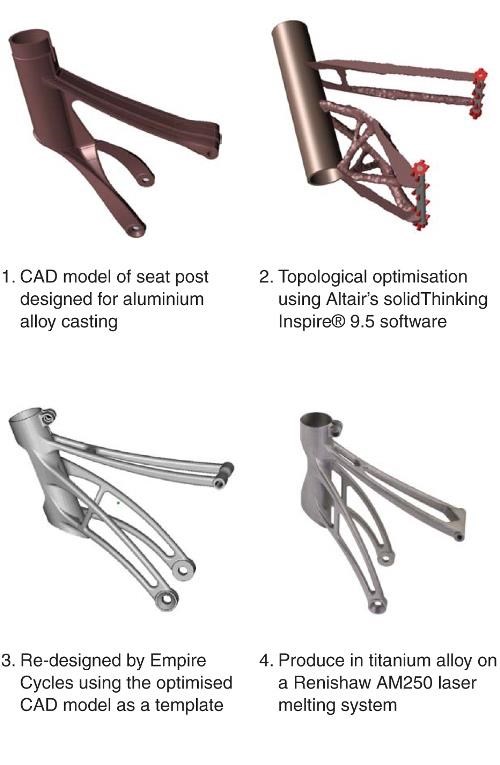

Renishaw, maker of a metal-based additive manufacturing machine, has collaborated with a British bicycle company to create what the companies say is the world’s first 3D-printed metal bike frame. Empire Cycles of northwest England designed the mountain bike to be stronger and lighter than previous designs, using a process called topological optimization along with Renishaw’s AM250 additive manufacturing system. The additive process offers design, construction and performance advantages that include: blending complex shapes or hollow structures with internal strengthening features, flexibility to make design improvements right up to the start of production, and the convenience of making customized one-off parts as easily as batches. The new titanium alloy frame, about 33 percent lighter than the frame that preceded it, was manufactured in sections and bonded together.

The two companies originally agreed to optimize and manufacture only the bike’s seat post bracket, but after the part’s successful production, improvement of the whole frame became the new goal. Starting with a full-size 3D printed replica of its current aluminium alloy bike, Empire sectioned the frame into parts that could be formed within the AM250’s 12-inch build height. The design was updated with guidance from Renishaw’s applications team and an optimized design—one that eliminates many of the downward facing surfaces that require wasteful support structures—was created using topological optimization.

Topological Optimization

Topological optimization software programs use iterative steps and finite element analysis to determine logical material placement. Material is removed from areas of low stress until a design optimized for load bearing is created, resulting in a model that is light and strong. Historical challenges in manufacturing these computer-generated shapes are overcome through the additive manufacturing process.

The AM250 uses a fiber laser to produce fully dense metal parts direct from 3D CAD data. Parts are built layer by layer, in thicknesses ranging from 20 to 100 microns, using a range of fine metal powders melted in a tightly controlled atmosphere. A fully welded vacuum chamber and low oxygen content in the build atmosphere allow processing of reactive materials, including titanium and aluminum.

The key benefit to Empire Cycles is the performance advantages derived from the additive process. The design has all of the advantages of a pressed steel “monocoque” construction used in motorbikes and cars, without the investment in tooling that would be prohibitive for a small manufacturer. “As no tooling is required, continual design improvements can be made easily, and as the component cost is based on volume and not complexity, some very light parts will be possible at minimal costs,” said Renishaw business manager Dave Bozich.

Light And Strong

The original aluminium alloy seat post bracket weighed 12 ounces. The first iteration of the hollow titanium version is 7 ounces. Comparison of the entire frame has the original bike frame weighing in at 4.6 pounds, with the redesigned additive-made frame at only 3.1 pounds. “There are lighter carbon fiber bikes available, but the durability of carbon fiber can’t compare to a metal bike,” says Empire Cycles managing director Chris Williams. “They are great for road bikes, but when you start chucking yourself down a mountain you risk damaging the frame. We over-engineer our bikes to ensure there are no warranty claims.”

Titanium alloys are denser than aluminium alloys. Therefore, the only way to make a titanium alloy part lighter than its aluminium alloy counterpart is to significantly alter the design to remove any material not contributing to the overall strength of the part. The companies believe further analysis and testing it could result in further weight reduction.

In addition to durability and corrosion-resistance, titanium alloys have an ultimate tensile strength of more than 900 MPa when processed using additive manufacturing. The seat post bracket was tested using the mountain bike standard EN 14766, and it withstood 50,000 cycles of 270 foot-pounds. Testing continued to six times the standard without failure.

Read Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More