Manufacturing Association Aids Shop’s Pivot to Ventilator Parts

After reaching out to the Austin Regional Manufacturers Association, a shop that typically serves oil and gas and heavy industry was able to quickly fill an order for ventilator parts.

Share

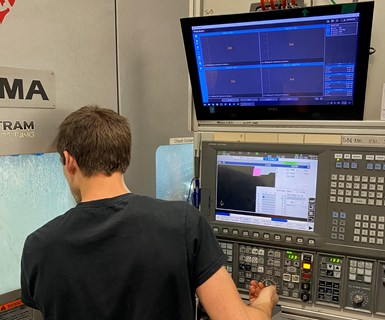

Five Wolfram Manufacturing employees quickly produced 60 ventilator parts using an Okuma Multus B400 multitasking machine and material the shop already had. Photo: Wolfram Manufacturing

Wolfram Manufacturing in Austin, Texas usually uses its multitasking machines to produce parts for oil and gas and heavy industry, but the coronavirus pandemic had the company wondering if it could produce parts for much-needed ventilators. It started reaching out to different organizations, including the Austin Regional Manufacturers Association (ARMA), to see if it could help. “I don't even know if there are parts that we can make in ventilators,” Wolfram Manufacturing President Nathan Byman said to ARMA Executive Director Ed Latson. “But if somebody has a need, please let us know. Pass it on to us.’” Within three days, the shop had an order for ventilator parts that needed to be complete by the next evening.

Wolfram got the call on a Sunday afternoon, and the parts needed to be ready to meet a critical shipping deadline at midnight on Monday. The order for 60 of these parts (which are roughly the size of a cell phone) came from SISU, an engineering firm that is helping to design a ventilator. Wolfram quickly mobilized five employees to open up the shop and start setting up to run the parts. “We got our setup done, we worked with raw material that we had in the shop, brought the part online and worked through the day and then hand delivered them to them Monday night,” Mr. Byman says.

While the timing was unusual, the parts themselves weren’t a challenge for the shop. “Our inspection requirements are very high, so that made the tolerances and everything on the parts very easy for us,” Mr. Byman explains. What did pose a problem was material, which led to the shop using its own stock. The customer managed to find a vendor that could get material to the shop by Monday morning, but it was all square. This wasn’t ideal, as the shop was using its Okuma Multus B400 — a lathe — to produce the parts. Fortunately, Wolfram had some 5-inch round drops in inventory from a project that was finished. The company worked to figure out how it could nest as many of the parts as possible into the barstock, around the turning and milling that had already been performed on the material. At first, Wolfram thought it was only going to be able to produce a portion of what the customer needed. “And then we figured out how to stack more so we could do half of what they needed. And then we figured out how to stack more,” Mr. Byman says. Eventually, by densely packing the parts and using all the material it had, the shop was able to fit 60 parts. “We were able to meet their whole demands on those,” he says. According to Mr. Byman, the ventilators with the parts Wolfram Manufacturing produced were deployed in New York, one of the areas hardest hit by the pandemic.

Related Content

-

WFL Milling Machines Feature Smart Sensors, Control System

M50 Millturn / 3,000 mm and M80X Millturn / 4,500 mm turning-boring-milling machines come equipped with a grinding attachment and a vibration-damped Silent ToolsTM Plus boring bar.

-

TTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.

-

Multitasking Machines Cut Days From Shop’s Setups

Adopting WFL Millturn machines enabled BWXT to condense operations and setups while also providing a simple way to simulate and secure processes.

Related Content

WFL Milling Machines Feature Smart Sensors, Control System

M50 Millturn / 3,000 mm and M80X Millturn / 4,500 mm turning-boring-milling machines come equipped with a grinding attachment and a vibration-damped Silent ToolsTM Plus boring bar.

Read MoreTTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.

Read MoreMultitasking Machines Cut Days From Shop’s Setups

Adopting WFL Millturn machines enabled BWXT to condense operations and setups while also providing a simple way to simulate and secure processes.

Read MoreIntegration, Automation and Green Tech Highlight JIMTOF 2022

Known as one of the largest machine tool trade shows in the world, the Japan International Machine Tool Fair (JIMTOF) has a reputation for being a machining technology show more than a machine tool sales event. And this year’s show in Tokyo — the first in-person Japanese machine tool trade show in four years — did not disappoint.

Read MoreRead Next

Shop Starts Work on Custom Drill for Ventilators Before Purchase Order Came

When this Indiana toolmaker saw an order for cutting tools to make ventilators for coronavirus patients, his workers started grinding before the customer officially hired them.

Read MoreAerospace Machine Shop Uses Past Prototype for Quick Ventilator Part Turnaround

Win-Tech Inc. is one of the many manufacturing facilities shifting focus to fulfill urgent medical needs during the coronavirus pandemic.

Read MoreAerospace Supplier Shifts to Tight-Tolerance Ventilator Parts: "We Weren't in This Business Two Weeks Ago"

Skilled Manufacturing Inc. is running seven days a week to produce ventilator parts that will help healthcare workers battle the coronavirus.

Read More