CAD/CAM Software Helps Shops Shift to Coronavirus Work

A sampling of CNC machine shops serving a variety of industries have this in common: They are using Mastercam CAD/CAM software to shift their focus and quickly produce medical supplies necessary to aid in responding to the coronavirus.

Share

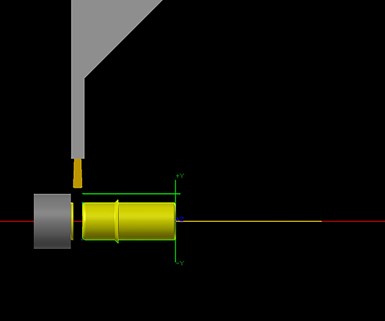

“I face the reducer orifice with a grooving tool, turn the OD rough and finish it with a grooving tool. I then drill the

two holes, part it off and I’m done,” says U.K. Precision’s Darren Vosper. He runs the entire operation through Mastercam’s Verify function to ensure it will work.

For the past five years, U.K. Precision Inc. has been making brass reducer orifices for oxygen concentrators. Under normal circumstances, these portable machines are used to deliver oxygen to people who have breathing-related illnesses — think chronic conditions such as asthma or chronic obstructive pulmonary disease (COPD), or even short-term conditions due to surgery or the flu. Recently, the devices have played a critical role in treating COVID-19 patients. They filter the surrounding air, compressing it to a specified density, and deliver purified oxygen to the patient via a nasal cannula or mask. Oxygen can flow fast, however, and the reducer orifices help regulate its speed.

As demand for this medical equipment increased, U.K. Precision responded. The small shop in Dallas, Georgia, makes complex parts in aluminum, titanium, 17-4 and 18-8 stainless, and exotics using several three- through five-axis machining centers, a small CNC plasma cutting machine, a surface grinder, and other manual equipment. It machines the brass reducer orifices on its Colchester Storm CNC lathe programmed with Mastercam CAD/CAM software from CNC Software Inc.

“It’s a very simple part with two ODs, front and back, between the flange that seals to the ID of the half-inch flexible tubing,” says shop owner Darren Vosper. Because the reducer orifices are necessary for the precise operation of the concentrator, they need to be made to spec. Each regulator orifice has a #17 (0.173-inch-diameter) hole at one end and a #50 (0.070-inch-diameter) hole on the other. “I face it with a grooving tool, turn the OD rough, and finish it with a grooving tool. I then drill the two holes, part it off and I’m done,” he explains. “The OD flange is finished to 0.297-inch diameter, and I’m using a 3/8-inch stock, so I’m not really taking off a lot of material. I’m able to machine all of it with one little tool.”

Mr. Vosper has many years of experience working with Mastercam. Over time, he developed a system whereby he adds manual code entries at the end of his programs, effectively creating his own posts. “I know when I pull the code out on my machine, I’m making parts quickly.” He also adds manual notes underneath each tool path. He notes the part geometry when he starts the machining process and how much material is removed at various stages, all back to the point where he touches off at the front of the part after he’s faced it. At that point, he knows how far he can feed the stock into the machine as the last part is cut. He can even determine how many pieces he can cut, depending on the length of the stock fed into the machine. “I add it as a note in my geometry file so I know straight away and can have the operation set up and running in less than 10 minutes,” Mr. Vosper says. Each piece takes about 90 seconds to machine.

Mr. Vosper was able to deliver the first batch of 50 reducer orifices in two days rather than the week he had originally proposed. Also, because the setup is so easy, he was able to churn out an additional 150 pieces the next day, and 175 pieces after that using the remaining stock.

“We are not on the front lines, but we are glad to do our part,” he says.

Providing Better Coverage

Another Mastercam customer, Century Mold, located in Rochester, New York, normally produces parts for the automotive industry. The injection molding company specializes in under-the-hood components for engine cooling, air-flow management, engine timing and HVAC. However, it redirected its energy when Rochester Regional Health called with an urgent request for better protective masks for its medical staff. Using Mastercam, the Century Mold team quickly designed a new mask that expands the protected area by wrapping from ear to ear and covering the user’s face, even past the chin.

Century Mold used Mastercam to design a new face mask to provide local healthcare workers with better coverage.

Within 24 hours, Century Mold had a mask prototyped. Only nine days after first beginning the project, the injection molder started mass production on the enhanced protective masks. The company uses both three- and five-axis machines programmed with Mastercam to complete orders. Currently, the shop is running seven days a week, producing 2,500 masks each day. The goal is to produce 1 million masks.

“We are thankful for everyone on the front lines fighting the coronavirus and happy we can contribute in some fashion. We are also extremely proud and truly grateful for our Rochester team who have been working endless hours, putting themselves at risk and spending time away from their families,” says Business Development Manager Jeff Ricotta.

Working Around the Clock

A Mastercam customer since its founding in 1999, Mechanical Drive Components Inc. in Chicopee, Massachusetts, is no stranger to long days of manufacturing. President and owner Joseph Giffune often completes most of the programming himself to make precision machined parts for the medical, industrial equipment, aftermarket automotive and aerospace industries.

Mechanical Drive Components relies on CNC milling to produce manifold blenders, which are used inside medical ventilators.

The ISO 9001:2015- and AS9100D-certified shop machines a variety of materials including aluminum, titanium, stainless steels, plastics, copper, brass and bronze. In addition to producing parts, the contract shop also offers turnkey processes for its customers, including fixture/process design in Mastercam, fixture production, part programming in Mastercam and preproduction sampling.

Recently, the company has switched most of its focus to producing components for use in the gas-mixing devices in ventilators used to treat COVID-19 patients. The shop has been running seven days a week with employees working 60 hours each week. “Our goal is to stay on this as long as possible,” Mr. Giffune says. Right now, he says it looks like the shop will be producing ventilator components into June or July.

Free Learning Available from Mastercam

While many aspects of life have been drastically changed since the coronavirus emerged, CNC Software is endeavoring to bring back a sense of normality. Several courses in Mastercam University will be offered for free until June 30, along with a free download of Mastercam Home Learning Edition. Free courses include: STEM: Principles of Machining, Mastercam Essentials, 2D Mill (Mastercam 2019 and 2020), 3D Mill (Mastercam 2019 and 2020), and Lathe (Mastercam 2019 and 2020).

Related Content

-

Five-Axis Turnkey Machine Halves Medical Shop’s Cycle Times

Horizontal five-axis machines cut cycle times in half at ARCH Medical Solutions – Newtown. But its leadership gives equal credit to a surprising factor: the OEM’s service department.

-

Kyzen Solvents Provide Ease of Cleaning for Medical Parts

The Metalnox line of solvent products are designed to improve reliability and increase the ease of cleaning in vacuum and vapor degreasing processes.

-

The Producto Group Appoints New Member to Board of Directors

Dean Schauer, the newest appointee to the company’s board of directors, is the current CEO and president of Confluent Medical Technologies.

Related Content

Five-Axis Turnkey Machine Halves Medical Shop’s Cycle Times

Horizontal five-axis machines cut cycle times in half at ARCH Medical Solutions – Newtown. But its leadership gives equal credit to a surprising factor: the OEM’s service department.

Read MoreKyzen Solvents Provide Ease of Cleaning for Medical Parts

The Metalnox line of solvent products are designed to improve reliability and increase the ease of cleaning in vacuum and vapor degreasing processes.

Read MoreThe Producto Group Appoints New Member to Board of Directors

Dean Schauer, the newest appointee to the company’s board of directors, is the current CEO and president of Confluent Medical Technologies.

Read MoreArch Cutting Tools Acquires Custom Carbide Cutter Inc.

The acquisition adds Custom Carbide Cutter’s experience with specialty carbide micro tools and high-performance burrs to Arch Cutting Tool’s portfolio.

Read MoreRead Next

Aerospace Machine Shop Uses Past Prototype for Quick Ventilator Part Turnaround

Win-Tech Inc. is one of the many manufacturing facilities shifting focus to fulfill urgent medical needs during the coronavirus pandemic.

Read MoreNew Business Plan Enables Shop to Increase Ventilator Part Production

KrisDee and Associates was able to increase production of a ventilator manifold from 90 parts per week to 780 parts per week thanks to changes the company started making months earlier.

Read MoreAerospace Supplier Shifts to Tight-Tolerance Ventilator Parts: "We Weren't in This Business Two Weeks Ago"

Skilled Manufacturing Inc. is running seven days a week to produce ventilator parts that will help healthcare workers battle the coronavirus.

Read More