At Purdue University, Emergency Production of PPE and Ventilator Fittings

After campus had largely shut down, several labs and departments at the venerated engineering school organized with local hospitals to manufacture critical parts needed to fight the coronavirus.

Share

The mask components in front are Purdue’s first two prototype designs working toward a final design to injection mold. Designed by second year grad student Kevin Del Rey. Background: the face shields and glasses, produced by second year grad student Soho Yun, are laser/water jetted out of sheets of plastic. All photos: Purdue University.

Through a Herculean display of institutional coordination, the Indiana Manufacturing Competitiveness Center (IN-MaC) — using its new digital manufacturing testbed at Purdue University — has pooled its resources with several other university departments and hospitals to manufacture critical parts needed by healthcare workers to battle the coronavirus, such as personal protective equipment (PPE) and ventilator fittings to increase overall ventilator capacity at regional and state hospitals. The Purdue collective is now involved in designing and manufacturing multiple ventilator fittings, developing a prototype fitting for hazmat suits, and producing up to 1,000 sets of face shields and glasses per day. The group is also in prototype development for a reusable N95-compliant mask with interchangeable filter cartridges.

Beginning around March 20th, after the university had largely shut down its campus, faculty, staff and students at Purdue University began coordinating with Purdue’s College of Health and Human Services, the Purdue Polytechnic Institute, the College of Engineering, the College of Pharmacy and its School of Nursing, as well as six research labs that all have design and production capability.

Secondary operation for female hazmat fittings produced at Purdue University.

Dr. Nathan Hartman, Purdue’s Dauch Family Professor of Advanced Manufacturing and co-Executive Director of IN-MaC, now leads a group of more than 50 people who are coordinating with regional and state hospitals to manufacture PPE parts via CNC machining and additive manufacturing technologies located on campus.

Dr. Hartman likens the university’s response to the federal Defense Production Act, albeit executed at the county level. “We're in direct connection with four of our hospital systems in the state of Indiana as well as Indiana University Medical Center and the Indiana University School of Medicine, who have been advising us a lot on the technical and clinical details about all of this so that we’re making things that can actually be used. We’re not just out here winging it as hobbyists.”

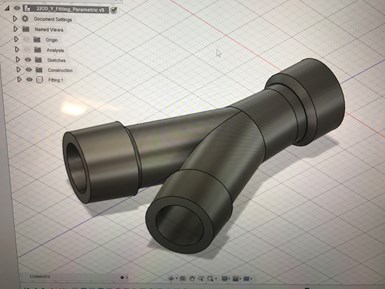

This CAD model, designed by a Purdue graduate student, is a Y fitting for splitting ventilators.

Jacob Coffing, a senior engineering tech for IN-MaC, says some of the parts being manufactured at Purdue are the result of a local hospital’s urgent problem: The hospital had two different types of hazmat suits with fittings that were not interchangeable. With the help of a graduate student, IN-MaC came up with a fitting that could interchange across the different suit types, allowing the hospital to use the same hoses on all 200 of its suits rather than only half of them. IN-MaC is machining the fittings on a Haas VF-2 VMC.

Meanwhile, Purdue is producing ventilator fillings — specifically smaller, straight inline fittings — at a clip of 60 per hour. More advanced fittings like elbow and Y fittings that require certain profiles to be milled can take anywhere from a minute to five minutes apiece in machining cycle time. Mr. Coffins says that all of these fittings are being produced via lights-out machining on a bar-fed Haas ST-20 lathe, with some parts moving on to a Haas VF-2SS machining center with an add-on fourth axis for final operations such as 3D profiling.

Jacob Coffing at Purdue University operates a Haas ST-20 lathe to machine hazmat suit fittings.

Overall production at Purdue ramped up quickly in mid-April, although Dr. Hartman warns that acquiring materials is already beginning to be a challenge as the materials supply chain begins to tighten.

“Purdue has a really wide industrial and community partner network, as well as tens of thousands of living alumni,” Dr. Hartman says. “And so, a lot of different channels basically asked us, what is Purdue doing to help? And it was a number of faculty members who simply just took it upon themselves to try to try to do something. Our state has not been hit as hard as New York or California or Seattle. Yet. But we are fairly certain it's coming. And we're trying to equip our health care systems as best we can. I don't believe that here at Purdue we’ll be anyone's sole supplier, but we can very much put a finger in the dike so the dike doesn't break.”

Related Content

-

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Related Content

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreRead Next

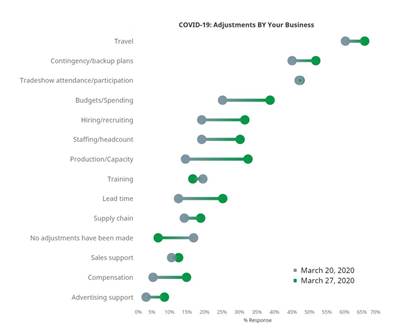

Manufacturers Begin Making Significant Adjustments to Production

As automotive OEMs closed facilities and states closed non-essential businesses to help combat the coronavirus, significantly more manufacturers made adjustments to production/capacity in last week’s survey.

Read MoreAdditive Manufacturing in the Age of COVID-19

Reporting from the front lines of the fight against Coronavirus — how my journey began.

Read More