Why Y?

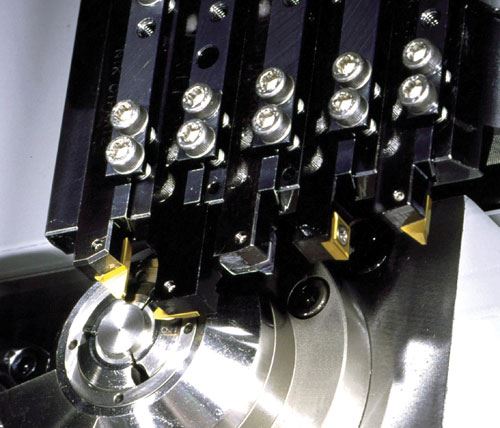

This toolholder takes advantage of a Swiss-type’s Y-axis motion to approach and engage the barstock from the side, which helps prevent “bird nesting.”

Share

Takumi USA

Featured Content

View More

Better chip control on Swiss-type lathes, for one. “Y” refers to the Y-axis/gang-tool-slide motion these machines use primarily to bring a different tool into position for a different turning operation. Once the new tool is positioned, the X axis moves it straight down into the top of the barstock to perform the operation.

That’s how it works using conventional tools, anyway. However, depending on the workpiece material, chip control can be an issue with this traditional approach. This spurred NTK Cutting Tools to develop its Y-Axis Control toolholder. Instead of approaching the barstock from the top, it takes advantage of the Swiss-type’s Y-axis motion to approach and engage the barstock from the side. Aided by gravity, the downward-facing chipbreaker on the tool’s insert directs chips down and away from the cutting zone. This helps prevent “bird nesting” around the workpiece during front-turning, back-turning and grooving operations. Plus, the tool’s rigid design is said to minimize vibration to ensure precise machining operations and quality surface finishes.

Although the company admits the Y-Axis Control tools look chunky (that’s the company’s word, not mine), each occupies only one slot on a gang-tool slide. Because of their bulkier design, though, only one or two tools can be installed on the slide, and a pair of them can’t be located side-by-side. Barstock size can vary depending on the tool’s position on the slide as well as the difference in overhang from a conventional X-axis tool (Y-Axis Control tools are slightly longer). The tools accept 35- and 55-degree ISO inserts.

Related Content

-

Form Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)