Workholding

Workholding Options Enhance Productivity

Hardinge Style-S master collets use interchangeable pads that can be changed without removing the master collet from the spindle, thus reducing change-over time. When loading bars, the shoulder of the pad locates against the front of the groove in the master collet.

Read MorePins: The Alternative To Parallels

These vise jaws use protruding, mechanical pins to repeatedly support workpieces either horizontally or at angles. They are said to allow quicker setups than conventional parallels.

Read MoreHigh-Density, Long Vises Available In Two Additional Capacities

Kurt Manufacturing says its high-density, long vises with two clamping stations can increase machining center productivity. Manual and hydraulic models are available in 4" and 6" capacities to increase existing machining center output.

Read MoreThe Part Is Longer Than The Lathe

Here is one custom machine builder’s system for producing a 40-foot part that has to be passed through the turning center and out the other side. INCLUDES VIDEO.

WatchFixturing Pull Clamps Precisely Locate Workpieces

Fixtureworks’ line of Imao pull clamps are said to feature an ergonomic design and precise, secure holding power. The clamps accurately locate workpieces using precision ground clamping pins and fixture-mounted clamp mechanisms, the company says.

Read MoreCold Clamping For Small, Delicate Parts

Icing plates use the adhesive power of ice to securely clamp parts of virtually limitless shapes and materials for milling and turning operations.

Read MoreA Deeply Holistic Approach

In its effort to streamline every step of the mold building process, this company has upgraded its deep-hole drilling capability with a new six-axis machine. A rotary table with magnetic workholding enhances this machine’s flexibility.

Read MoreHigh/Low Chucking

Northfield Precision announces the development of two methods of high/low chucking: “on the fly,” and “cycle interrupt. ” Using a proprietary valve system, delicate parts can be rough machined and finished in one chucking. The cycle starts with the jaws clamping at high pressure for roughing, then dropping down to low pressure for finishing.

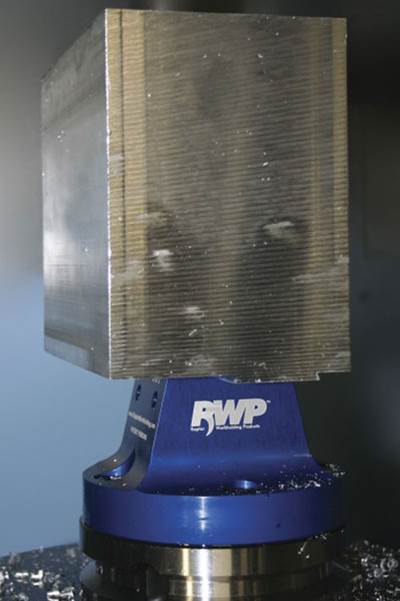

Read MoreZero-Point Clamping System

Quick Point, the zero-point clamping system from Lang Technovation, is said to be simple, safe and precise. Features include a holding power of 13,227-lbs down force, repeatability of less than 0. 00019" and overall pallet height of 1.

Read MoreJob Shop-Developed Dovetail Fixture Takes Wing

Two aerospace job shops in California collaborated to produce a workholding fixture that allows any shop to set up a fully fixtured pallet dedicated to a five-axis job and then store the fixtured pallets for immediate use whenever the job repeats.

Read More

.jpg;maxWidth=300;quality=90)