Tooling

Dillon Manufacturing Launches New Line of Vise Jaws

Dillon Manufacturing’s new line of vise jaws comes in a variety of materials, blanks and hardnesses, with an option for a wear-resistant Carbinite coating.

Read MoreBig Kaiser Releases Smallest Yet EWN Boring Heads

Big Kaiser has debuted two smaller sizes of its EWN Smart Damper precision boring heads, which it says eliminate vibration in deep-hole finish boring.

Read MoreWalter Xtra-tec XT M5012 Comes Fully Ground or Sintered

Walter’s Xtra-tec XT M5012 ships in fully ground and sintered configurations, increasing the cost-effectiveness and precision of this versatile face mill.

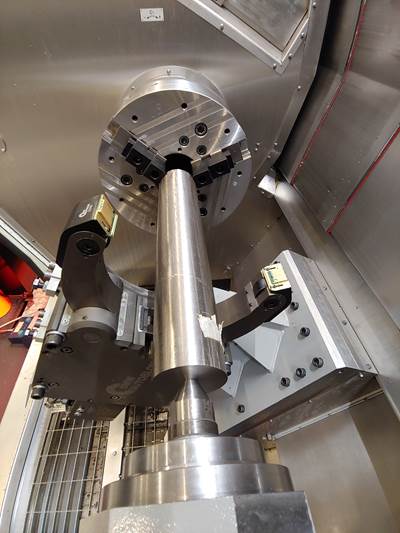

Read MoreClamping Solution Facilitates Large-Part Vertical Machining

Mitee-Bite Products’ fixtures demonstrated their powerful clamping support in a project with Akron Gear & Engineering to vertically hold a 1-ton ring during machining.

Read MoreMidaco Hydraulic Docking System Requires No Hoses

Midaco has updated its automatic pallet changer system with a simple-to-use hydraulic docking system that requires no hose management.

Read MoreRoyal Products Releases Free 2021 Product Catalog

Royal Products' free, 168-page 2021 Machine Tool Performance Accessories catalog includes new additions to enhance precision metalworking productivity.

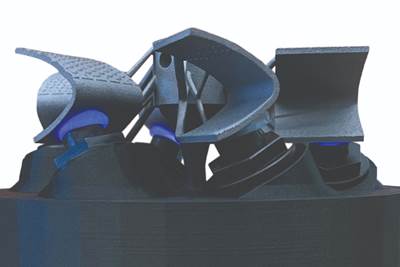

Read MoreChoosing Workholding to Meet Machining Challenges

When it comes to workholding, shops can choose from options that can provide flexibility, help increase throughput and enable five-axis machining.

Read MoreRoyal Products Hires New Regional Business Manager

Royal Products has hired Kendal Glotzbach as its new regional business manager for Indiana and Michigan.

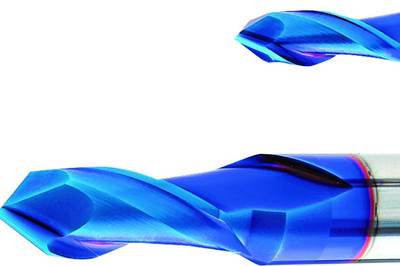

Read MoreWhy Binderless CBN Inserts Turn Titanium Faster

A new formulation of cubic boron nitride could provide a more solid alternative to cemented carbide as finish-machining becomes more demanding.

Read MoreCarmex Multi-Function Milling Tool is Versatile, Durable

Carmex’s Multi-Function Milling Tool performs six milling operations on a single tool, while maintaining high performance and durability.

Read More