Tooling

Quick-Change Tooling Available with C3/C4 Coupling

Tungaloy has expanded its TungCap PSC quick change tooling system to include cutting heads and clamping units in C3/C4 coupling size.

Read MoreBig Kaiser Celebrates 70th Anniversary

The company, which was founded in 1948 in Switzerland, has continued its founder’s mission of developing cutting tools that keep up with machine tool technology.

Read MoreInserts Add Flexibility to Grooving Tool Line

Tungaloy is growing its TetraMini-Cut grooving tool family by adding items to its TCG18 insert lines.

Read MoreReusable Master Jaws Reduce Setup Time

Kurt’s DoveLock master jaws are designed to be installed in replacement of standard cap screw jaws for quick-change capabilities.

Read MoreSolid Carbide Thread Mills Increase Life, Improve Thread

North American Tool Corp. has released a line of standard solid carbide thread mills with a helical flute design.

Read MoreSolid Carbide Micro Drill Meets DIN 1899 Standards

Walter USA has released the DB130 Advance, its smallest solid carbide micro drill

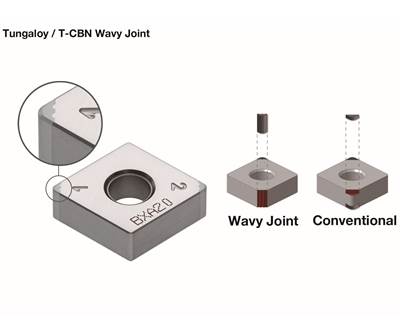

Read MoreInserts' CBN Brazing Treatment Enables Deeper Cuts

Tungaloy introduces WavyJoint cubic boron nitride (CBN) inserts with a CBN brazing technology for higher productivity in hard-turning operations.

Read MoreMore Flutes Give Thread Mill Greater Performance

Constructed of MT8 carbide with Carmex’s BLU coating, the FMT thread mill is designed to deliver accurate thread geometry and surface quality in shorter cycle times.

Read MoreHow Intelligent Clamping Technology Can Contribute to Process-Flow Optimization

Germany’s Metav 2018 trade fair presented various hands-on solutions in regard to Industry 4.0, automation, digitalization and data-driven manufacturing. One topic that stood out was intelligent clamping technology with integrated measurement capabilities to generate data to optimize machining processes.

Read MoreHaimer to Host Open House at North American Headquarters

The event will include speakers, demonstrations and technologies based around the theme of “Explore Industry 4.0.”

Read More