Milling Tools

Sandvik Coromant Milling Tool Boosts Productivity in Steel Machining

CoroMill MR80 is designed for challenging roughing operations in a wide range of face and profile milling applications in steel and stainless steel.

Read MoreEmuge-Franken End Mill Wins ANCA's Tool of the Year Award

Emuge-Franken received the award for its specialized tool based on the new Cera-Cut end mill design.

Read MoreGreenleaf End Mills Provide High Metal Removal Rates

Westec 2023: Xsytin-360 end mills provide high material removal rates and result in increased productivity on a wide range of materials.

Read MoreIMCO End Mills Enable Aggressive Cutting Parameters

Westec 2023: M936 Pow-R-Feed end mills enables users to make toolpath moves without slowing down.

Read MoreSumitomo Milling Series Promotes Stable Machining

Westec 2023: The DMSL delivers excellent surface finish even at high feed rates of 0.138 IPT or more due to its arc-shaped edge.

Read MoreWalter Milling Tools Cut Difficult-to-Machine Materials

Walter has expanded its solid carbide milling offering with new inch tools for hard, high-temperature alloys.

Read MoreEmuge-Franken End Mills Provide Optimized Vibration Dampening

Cera-Cut end mills are designed to produce high metal removal rates in challenging nickel-based alloys.

Read MoreHorn Milling System Provides Stable, Smooth Milling

The M409 tangential milling system features precision-ground inserts to achieve a high surface quality at the bottom of the groove and on the flanks.

Read MoreTungaloy Drills, Milling Inserts Provide Enhanced Stability

Tungaloy has expanded its DrillForceMeister and TecMill lines with new drill bodies and milling inserts.

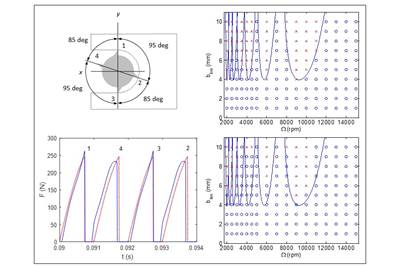

Read MoreThe Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

Read More

.png;maxWidth=300;quality=90)