Machining Centers

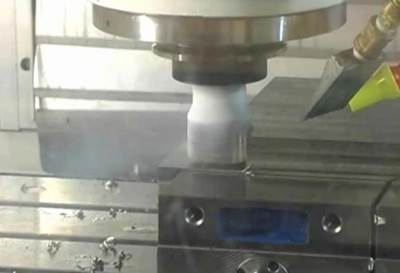

Micromachining Powder Metal on a VMC

By refining its micromachining process for powder metal tool steels, this shop has reduced production costs, lead times and secondary bench work for complex tooling components.

Read MoreFully Expandable HMC

The Akari HS-450i 400/500-mm HMC features X-, Y- and Z-axis travels measuring 25.2" × 24.0" × 26.8" and a work envelope measuring 29.5" × 39.4".

Read MoreBig Machining for a Big Gear

Here’s an example in which MAG demonstrates it knows how to use machine tools as well as build them.

Read MoreDesign the Parts Around the Process

To guarantee that components for a new helicopter could be readily produced, the company looked at the capabilities of available machine tools in the market first, and then finalized the design of the components accordingly. It created a Precision Components Technology Center to embody this concept as a process for R&D prototype work. What has emerged is a flexible production model that can be duplicated at its other facilities.

Read MoreHow Electro-Chemical Machining Works

Machine tool builder EMAG has produced a very nice video that explains and illustrates how the electro-chemical machining (ECM) process is able to perform simple deburring operations as well as produce precision surfaces and shapes.

Read MoreCell Works the Night Shift

At this aerospace and medical component manufacturer, a Doosan HMC paired with a flexible pallet magazine and cell controller from Fastems has increased production and part quality while eliminating variation throughout the production chain.

Read MoreVideo: Cryogenic Machining of Titanium

Through-tool liquid nitrogen turns the tool into a heat sink, extending tool life.

WatchVideo: Machining Long Parts Through a Small Machining Center

Video from Chiron America demonstrates the company’s Multi-Profile System, which combines a machining center with in-feed and out-feed accessories so that the compact machine can mill and drill long parts.

WatchHow Cameras Improve Capacity

Web cameras provide an inexpensive way to bring remote processes together, and to improve timing and confidence in unattended machining.

Read MoreMachining Complex Parts on a Five-Axis VMC

Makino’s F5-5XR VMC combines high-performance hard milling with multi-axis capability for increased accuracy, speed, flexibility and productivity.

Read More

.jpg;maxWidth=970;quality=90)