Machines

High-Production Multitasking Becoming More Flexible

Platforms such as multi-spindles and rotary transfer machines remain well-suited for high-volume production but are now more accommodating to smaller batch sizes.

WatchMetal Additive Manufacturing: Multitasking’s Latest Trend

Why are an increasing number of machine tool builders adding additive manufacturing to their equipment’s already versatile machining capabilities? Because additive and subtractive are complementary.

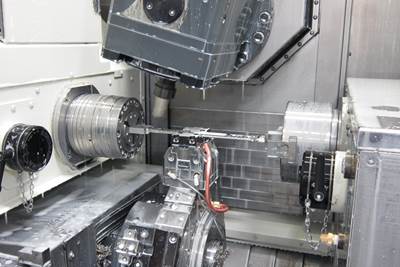

WatchTurn-Mills: Being About the B-Axis

With the addition of powerful B-axis milling spindles and automatic toolchangers, turn-mills combine the best of milling and turning worlds.

WatchMultitasking Machining Equipment: Now the New Normal

Machine tools that can perform turning, milling and other operations on one platform offer process efficiencies that more and more shops are leveraging to their advantage.

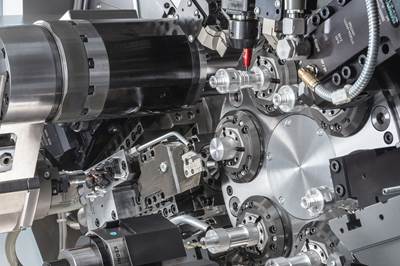

Read MoreSwiss-Types Offer Advantages Beyond Watchmaking

CNC sliding headstock lathes are becoming more popular among traditional machine shops for their multitasking capabilities, some offering B-axis milling spindles.

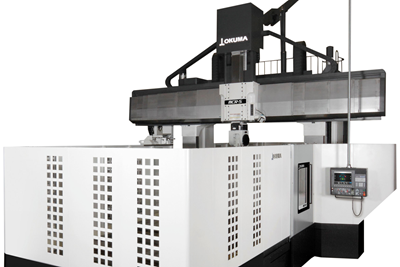

WatchOkuma’s MCR-S Roughs, Finishes Press Dies in One Setup

Okuma's MCR-S double-column machining center reduces cycle time to rough and finishing press dies in one setup.

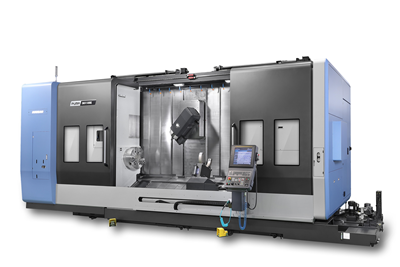

Read MoreDoosan Puma SMX5100L Turn-Mill Has More Chuck Sizes

The Doosan Puma SMX5100L is a twin-spindle, multi-tasking turn-mill center designed to complete complex parts in a single setup, with chuck sizes available in 15, 18 and 21 inches.

Read MoreStandardization Leans the Way to High-Mix Automation

An increasingly digitalized, lean manufacturing process begins with a common selection of cutting tools and five-axis machining fixtures.

WatchHermle USA Expansion Doubles North American Headquarters

The additional 15,000 square feet of space includes a Technology and Innovation Center, an apprenticeship and training area, additional warehouse space, and a customer hospitality area.

Read MoreKitamura Announces New VP of Sales, Distributor

Kitamura has announced that Dave Lucius is joining its leadership team as vice president of sales for the Americas, and that Tipton Technologies is its new exclusive representative in northern Ohio.

Read More

.jpg;maxWidth=300;quality=90)