Horizontal Machining Centers

HMC Designed for Rapid Metal Removal for Aerospace, Automotive

Doosan Machine Tools introduces the NHP horizontal machining center series, built for rapid metal removal rates.

Read MoreHMC Skiving Consolidates Gear Machining

A rigid machine platform and the right CNC promise to reduce stackup error and cycle times for both established gear-making operations and new players.

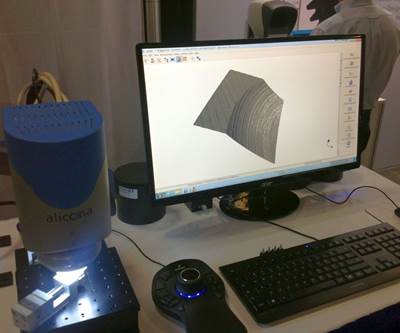

Read MoreHot Temperatures (and Technologies) at Eastec 2017

Eastec’s peculiar Massachusetts venue offered the chance to sample a broad variety of advanced manufacturing technologies. Here is a slideshow and some impressions from the trade show.

Read MoreMachines Combine Deep-Hole Drilling, Milling for Moldmaking

Amerimold 2017: Unisig USC and USC-M deep-hole drilling and milling machines are designed to allow moldmakers to combine operations, reduce setup time, increase accuracy and eliminate mold design restrictions associated with traditional machining centers.

Read MoreToyoda Opens Technology Center in Michigan

The center shares space with the company’s machine remanufacturing division and will serve the Great Lakes region.

Read MoreSMTCL Americas Hosts Open House Event

The company offered a number of discounts on the machine tools in its offering in collaboration with its partners.

Read MoreMitsui Seiki USA Appoints Chairman, CEO, COO

Together, they will manage inventory mix, business strategy development and implementation, and financial oversight.

Read MoreFive-Axis Machine Features Inverting Mill-Turn Table

Eastec 2017: Based on a horizontal machining center platform popular with automotive OEMs, Grob Systems’ G-series universal machining is designed for manufacturers in medical, aerospace, tool and mold, and other industries.

Read MoreAutomated Deep Drilling for Medical Applications

Eastec 2017: Available from Advanced Machine & Engineering, Tibo Tiefbohrtechnik’s E10 series of deep-drilling machines is designed to offer the precision required for bonescrews and other medical parts.

Read MoreComplete Machining of Large Aerospace Parts

Machine Specialties Inc. needed to produce large parts with a constantly increasing degree of complexity. The M120 Millturn from WFL enables the shop to process large components in only one clamping.

Read More

.jpg;maxWidth=300;quality=90)