Automotive

An Analytical Approach To The Outsourcing Decision

The decision to manufacture in-house or send work overseas should not be based solely on labor cost. After an honest evaluation of its machining processes, this OEM found it was more profitable to bring work back in-house.

Read MoreHow Clean Is "Precision" Clean?

Specially engineered aqueous cleaning equipment is normally necessary to obtain the cleanliness levels automakers demand. There are general system attributes that a precision cleaning system should possess.

Read MoreAuto Supplier Uses System To Gage Thread Depth And Reduce Costs

Each of the thousands of output axle shafts machined by American Axle&Manufacturing (AAM) (Detroit, Michigan) has at least six mounting holes, permitting the half shaft to be bolted securely to the flange. The proper location, depth and thread in each hole is so critical that each hole must be inspected completely-without compromising production rates of more than 200 parts per hour, per gage. Manual inspection was proving to be slow, unreliable and tedious for the operators. That's when the company's plant engineers began searching for an automated thread verification system.

Read MoreCylinder Head Porting On A Turn/Mill Machine

This complex milling operation is performed effectively on a machine that does turning.

Read MoreUnattended Honing On A Vertical Chucker

An air-gage-monitored honing system added to an inverted vertical spindle chucking lathe allows unattended turning, boring and honing on one machine for greater process flexibility.

Read MoreHow To Machine Pure Abrasion

Powder metal parts have become the darling of the auto industry, but they can be a demon for the shops that must machine the finishing touches. This shop has found that the keys to success machining such abrasive materials are proper cutting tool selection and continuous tool wear monitoring.

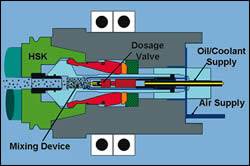

Read MoreUnderstanding MQL

Minimum quantity lubricant can save money, improve tool life and improve the part finish. But it may involve changes to both the equipment and the processing strategy.

Read MoreVertical Machining Centers For Volume Production

At this model plant for lean manufacturing, Parker Hannifin personnel became convinced that the simple approach was the strongest choice for the application. Part of the lesson learned at this plant is that the most difficult part of going lean may lie in the discussion.

Read MoreSteering To Greater Flexibility

Re-tool aging dedicated machines? For this plant, it makes more sense to spend a bit more to replace them with new, more flexible, machining centers.

Read MoreHumility, Inc.

This shop has capabilities similar to others. It hires employees who have no experience. What sets the shop apart and accounts for its success is an unusual attitude of service toward customers.

Read More

.jpg;maxWidth=300;quality=90)