Additive Manufacturing

After the Build Is Done Why Do the Bills Keep Coming?

When your additively manufactured part is done printing, you just pull it out of the machine and start using it, right? Not even close.

Read MoreStratasys Launches AM Certification Program

Stratasys has started the Additive Manufacturing Certification Program in North America, designed to bridge the AM skills gap.

Read MoreWhy Does My AM Part Cost So Much?

The machine, the facility and the material are just three costs behind the price tag.

Read MoreStratasys Spins Off STEP Technology into Independent Company

Evolve Additive Solutions will develop the technology, which aims to deliver high-volume additive manufacturing at speeds comparable to traditional processes.

Read More3D Printer Enables Toolmaker to Produce Fixturing, End-Use Parts

A 3D printer helped a tooling manufacturer quickly and cost-effectively create fixturing for its tools and, eventually, end-use parts for customers.

Read MoreStratasys, Eckhart Enter Three-Year Collaboration Agreement

Stratasys and Eckhart Inc. announced a three-year collaboration agreement to advance the adoption of 3D printing for factory tooling in North America.

Read MoreEckhart Opens Advanced Technology Center

The company’s technology showcase will include engineering and assembly of its autonomous guided vehicles and an additive manufacturing laboratory, among other things.

Read MoreEnd-to-End Medical Manufacturing, Starting with Additive

The March 2018 issue of Additive Manufacturing magazine highlights a medical manufacturing process that begins with electron beam melting (EBM) additive manufacturing.

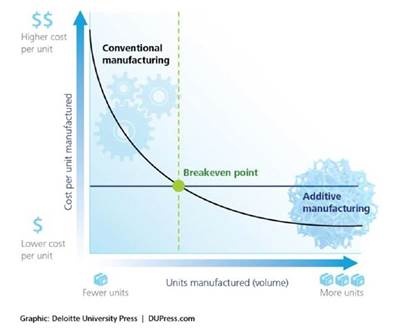

Read MoreA Benefit of Additive Manufacturing: No Tooling Is Required

Manufacturers need to understand the cost curves in regard to “conventional” manufacturing practices and those of additive manufacturing.

Read MoreMetal AM System's Four Lasers Increase Productivity

To improve additive manufacturing productivity and lower cost per part, Renishaw has launched the RenAM 500Q.

Read More

.jpg;maxWidth=300;quality=90)