Wintriss to Showcase New OEE and Data Collection Software Features

Eastec 2021: Wintriss claims the software can increase manufacturing capacity and profitability by identifying and quantifying excessive production losses and bottlenecks.

Share

Takumi USA

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

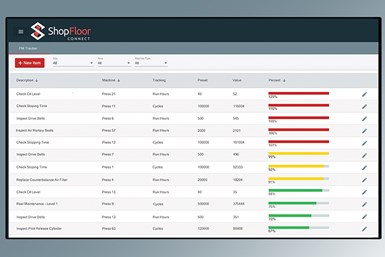

Wintriss Controls Group will demonstrate new features in its ShopFloorConnect overall equipment effectiveness (OEE) and data collection software at Eastec 2021, booth 5012.

Wintriss claims the latest functionality in ShopFloorConnect software promotes increased efficiency and reduced downtime, including when remote monitoring is required. The software can increase manufacturing capacity and profitability by identifying and quantifying excessive production losses and bottlenecks.

ShopFloorConnect collects downtime and production efficiency data from every machine in a variety of industries, including discrete manufacturing, metal forming, metal fabrication packaging, food and beverage. The data is displayed in real time, and manufacturing reports are produced in a variety of formats. At Eastec, Wintriss will introduce the new ShopFloorConnect preventative maintenance (PM) tracker, which enables users to track items by run hours or machine cycles, issue targeted alerts when an item requires PM and track the maintenance work history for all machines.

ShopFloorConnect 6.0 includes a new interface that Wintriss claims will enable users to set up two-way data sharing with any ERP or MES software.

Related Content

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

.jpg;maxWidth=300;quality=90)