Winco Introduces Two New Spirit Level Types

J.W. Winco Inc. has added a new cross spirit level, GN 2276, and screw-on spirit level, GN 2283, to its offerings. Both come in two sensitivity ratings.

Share

Takumi USA

Featured Content

View More

Cross spirit levels GN 2276

According to J. W. Winco Inc., spirit levels can be used almost anywhere. In addition to needing no power supply or data lines, they are robust, simple to adjust and can be added at any time. Winco has expanded its selection of bull’s eye and screw-on spirit levels with two new models.

The cross spirit levels GN 2276 combine two perpendicular linear levels within a single, round aluminum housing. This design shows the alignment in two planes at once, which is meant to make installation and leveling easier and faster. Winco offers two versions: One with a flat underside for direct installation and a second version with an alignment ball on the bottom side for adjustment. The second type, designated “JV,” allows the spirit level to be adjusted using the three installation screws to set a zero point adapted to the situation with a variance of ± 2 degrees.

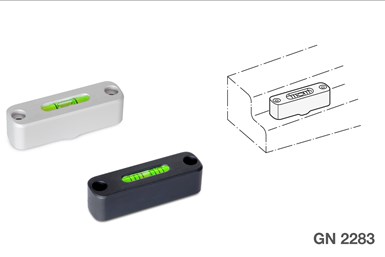

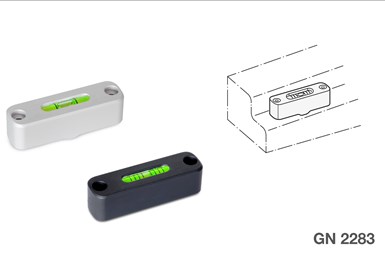

Screw-on spirit levels GN 2283

The company also offers screw-on spirit levels in an aluminum housing. While the existing screw-on spirit levels GN 2282 have been in a deep-drawn, non-adjustable sheet metal housing, the new GN 2283 has the same properties as the right-angle spirit level GN 2276. The new screw-on spirit level is available both as a directly mountable, flat version, “AV,” and as an adjustable version, “JV,” with an alignment cam on the bottom. The spirit level is adjusted during installation using the two socket cap screws.

Both the new linear and cross spirit levels are available in two sensitivity ratings: Two millimeters of bubble movement correspond to either six or 50 minutes of arc. Winco offers a detailed conversion table to illustrate which sensitivity is best for various applications, which is meant to simplify comparing height differences, degrees and minutes of arc.

Related Content

-

Help Operators Understand Sizing Adjustments

Even when CNCs are equipped with automatic post-process gaging systems, there are always a few important adjustments that must be done manually. Don’t take operators understanding these adjustments for granted.

-

The Link Between CNC Process Control and Powertrain Warranties

Ever since inventing the touch-trigger probe in 1972, Sir David McMurtry and his company Renishaw have been focused on achieving process control over its own manufacturing operations. That journey has had sweeping consequences for manufacturing at large.

-

The Many Ways of Measuring Thickness

While it may seem to be a straightforward check, there are many approaches to measuring thickness that are determined by the requirements of the part.

.JPG;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)