Tungaloy Expands Turning Tool Lines With Left-Handed Inserts

The TCS18 and TCL18 inserts are designed for left-hand cuts, expanding product lines that previously offered only right-hand inserts.

Share

Takumi USA

Featured Content

View More

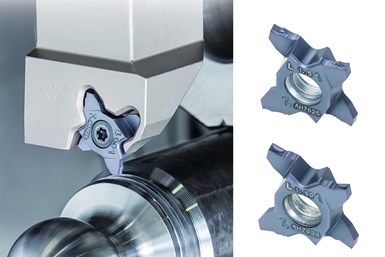

Tungaloy has added 37 left-hand inserts to the TCS18 and TCL18 insert lines of the TetraMiniCut grooving and parting tool series.

Featuring parting and grooving inserts with four economical cutting edges, TetraMiniCut offers an insert clamping method that is said to ensure secure retention and high edge repeatability, machining accuracy and tool life predictability.

The series is now introducing TCS18 and TCL18 inserts designed for left-hand cuts, expanding the product lines that, until now, has offered right-hand inserts only. Grooving and parting tools commonly used in most of the operations performed in conventional CNC lathes and Swiss machines are right handed. As highly advanced multitasking machines with multiple spindles and turrets are gaining popularity to maximize productivity, the need for left-hand tools is increasing as well, which enable simultaneous machining on the right and left-hand spindles of such machines.

TetraMiniCut’s TCS18 and TCL18 geometries feature pressed-to-form 3D chipbreakers that increase chip control. TCS18 incorporates four cutting edges with an optimal rake angle that provides the cutting edge with a good balance of strength and sharpness. TCL18 has cutting edges with a large rake angle that generates light cutting action and reduced cutting load for machining stability.

With this expansion, TetraMiniCut left-hand tooling can now be purchased off the shelf at less costs, while enabling more end users to use the full capabilities of TetraMiniCut’s tool stability and accurate edge repeatability and productivity over an expanded range of grooving and parting operations.

Related Content

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

Form Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

-

How to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

.jpg;maxWidth=300;quality=90)