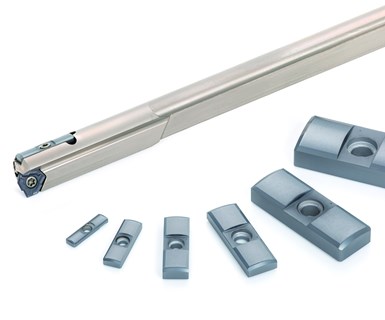

Tungaloy Adds Fracture-Resistant Guide Pads to DeepTri-Drill Line

Tungaloy’s DeepTri-Drill line of indexable deep hole drills now includes FH3135 grade guide pads.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Tungaloy’s DeepTri-Drill line of indexable gundrills now includes FH3135 grade guide pads. These guide pads were developed specifically to enhance thermal crack resistance when machining with water-emulsifiable oils.

DeepTri-Drill is a line of indexable-insert gundrills designed for productivity and application security when drilling deep holes while eliminating the need for regrinding.

The tribological conditions during gundrilling between the guide pad surfaces and the wall of the hole being drilled are far more severe than those during other applications, Tungaloy explains. While straight cutting oils have long been preferred, more manufacturers are using more environmentally conscious water-emulsifiable or soluble oils over petroleum-based coolants. These oils have lower lubricity and can adversely affect the guide pad quality during gundrilling.

The dedicated carbide substrate of the FH3135 guide pad provides enhanced resistance to fracturing and thermal cracking, reducing the risk of guide pad breakage for use with these lower-lubricity oils. In addition, the new guide pad features a double-chamfer geometry on the corners of both ends, smoothing entry into the guide bushing or pilot hole to limit vibration impact and further decrease the risk of rupture.

Related Content

-

Emuge-Franken's New Drill Geometry Optimizes Chipbreaking

PunchDrill features patent-pending geometry with a chipbreaker that produces short chips to control machining forces.

-

Kennametal's Expanded Tooling Portfolio Improves Performance

The company has launch eight new products that expand on and support existing platforms across multiple applications.

-

Ceratizit Product Update Enhances Cutting Tool Solutions

The company has updated its MaxiMill 273-08 face mill, WPC – Change Drill, as well as the HyPower Rough and HyPower Access 4.5-degree hydraulic chucks.