Tormach xsTech and PathPilot Hub Enable Remote CNC Learning

Tormach’s xsTech provides a small, fully featured option for CNC machining, and is fully compatible with PathPilot Hub, Tormach’s free digital twin software.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

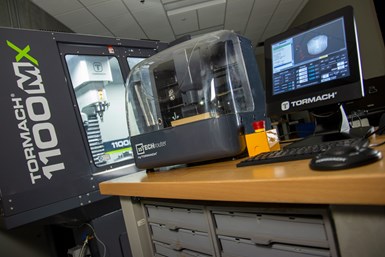

Tormach Inc’s xsTech Router Mill, a ready-to-use tabletop system with full CNC capabilities, is a small-but-versatile CNC system for cutting plastics, wood and aluminum.

Tormach recommends xsTech, which comes ready to run and requires no assembly, for students learning CNC fundamentals. It plugs into a standard 120V wall outlet, with an available 230V version for customers outside of the US. The xsTech comes with a wide variety of features including a 10.4” Touchscreen PathPilot Controller; keyboard, mouse and jog shuttle; WiFi module; electronic tool setter; 16-piece carbide cutting tool set; see-through enclosure for dust control and safe use; and several ER11 collets.

“The xsTech is small and easy to use, and like all Tormach CNC machines, it uses our award-winning PathPilot control software,” says Andrew Grevstad, Tormach’s business development director. “PathPilot is intuitive and provides newcomers with the perfect entry into understanding CNC fundamentals.”

Tormach particularly recommends PathPilot Hub for teachers and remote educators. It provides a full software interface for any Tormach machine, including the xsTech, and allows students to learn CNC programming from a virtual hub. According to Lori Morrison Bufalo, Tormach’s marketing director, teachers have been able to make use of the free software during the COVID pandemic.

“Teachers are using PathPilot Hub to teach students remotely,” she says. “When they are able to come into school to use the Tormach mills, the students have already learned their programming skills and can make their proven parts.”

PathPilot Hub provides a virtual digital twin, allowing users to test anything they might wish to do on a physical machine like the xsTech.

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

-

Automated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.