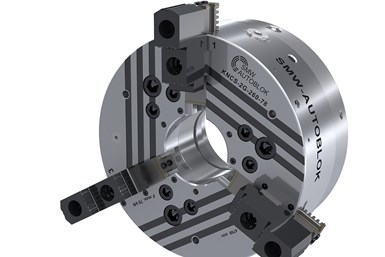

SMW Autoblok Releases Quick-Change Power Chuck

SMW Autoblok claims the KNCS-2G enables users to change jaws in under one minute, reducing downtime during changeovers.

Share

Takumi USA

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

SMW Autoblok, a designer and manufacturer of rotational chucks, stationary workholding, tooling and custom engineered solutions for the machine tool industry, introduces the KNCS-2G power chuck. According to the company, the KNCS-2G enables users to change jaws in under one minute, reducing downtime during changeovers.

The KNCS-2G is said to be ideal for lathe and mill-turn applications where frequent part changes are prevalent; it features an optimized lubrication system with additional channels and grease pockets that are integrated into the jaw guide ways to enable the chuck to operate for three shifts before additional lubrication is needed. The additional sealing and new lubrication system reportedly makes the KNCS-2G suitable for mass production in all working conditions and ensures constant clamp force and extended life.

SMW Autoblok claims the wedge bar system guarantees unmatched accuracy and rigidity. In addition, a low loss of grip force due to centrifugal force compensation, along with no counterbalance weights, makes the chuck vibration-free for high-speed applications.

The chamfered guide ways of the KNCS-2G are designed to enable quick change of jaws, making it flexible for operations needing multiple jaw changes and setups. The Proofline sealed chuck body, base jaws and wedge bars also provide additional protection against chips, lubricants and other debris.

The chuck body and internal parts are case hardened for increased chuck life and high rigidity, precision and durability. The KNCS-2G is interchangeable with SMW Autoblok’s standard KNCS-N chucks and existing master jaws can still be used without sealing. Sizes are available in 170-630 mm.

Related Content

-

Rego-Fix’s Center for Machining Excellence Promotes Collaboration

The new space includes a showroom, office spaces and an auditorium that will enhance its work with its technical partners.

-

Simulation and Tooling Secure High-Value Work

Simulation software and careful attention to tooling parameters have enabled Major Tool to take on ambitious projects with its complex machinery.

-

PowRgrip Responds to Three Tooling Trends

Rego-Fix’s PowRgrip tooling system has expanded over the past 20 years to incorporate a wider range of tool sizes, as well as automation.