Open Mind's HyperMill 2020.1 Provides Improved Five-Axis Strategies

Open Mind Technologies has introduced HyperMill 2020.1, featuring enhancements to 3D and 5-Axis Machining for complex part manufacturing.

Share

Open Mind Technologies’ HyperMill 2020.1 features enhancements to 3D and 5-axis machining as well as new automation and additive manufacturing strategies.

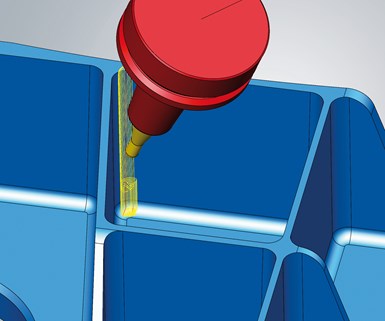

Corner Rest Machining strategies for 3D and five-axis techniques are said to provide benefits in complex machining applications, including mold and die. Corners can be machined largely by vertical stroking motions. Afterward, traditional Z-level steps can be used to blend with the vertical section and the lower floor area. The top section has an automatic surface extension to enable the production of sharp edges.

A new 5-Axis Blade Tangent Milling strategy is designed to improve surface quality when milling with conical barrel cutters that have a large primary angle.

The Mill-Turn module’s Automatic Contour Feature Splitting functionality enables HyperMill to automatically determine the area to be machined based on the turning contour. The grooving job will automatically recognize if a contour is a groove, making it faster and easier to program certain areas, the company says.

HyperMill’s Automation Center enables users to automate the job list creation processes in hyperCAD-S, serving as both a development and runtime environment. New features also include the ability to select and position the clamping device, as well as to define a uniform process for all programmers.

HyperMill’s Additive Manufacturing process provides efficient hybrid processing with simultaneous additive manufacturing and subtractive machining on one machine tool. The software offers flexible strategies for additive material applications, including filling strategies for both planes and freeform shapes and in 2D and 3D sections. Applications also include hybrid machining to fix damaged parts and additive machining of an existing component.

Related Content

-

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

-

Automated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

.jpg;maxWidth=300;quality=90)